Leather ball producing technique

A production process and ball technology, applied in the field of ball production technology, can solve the problems affecting the appearance and quality of finished balls, unnatural and beautiful arc, discontinuity, etc., and achieve the effect of perfect three-dimensional sense, smooth connection, and neat butt edges.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

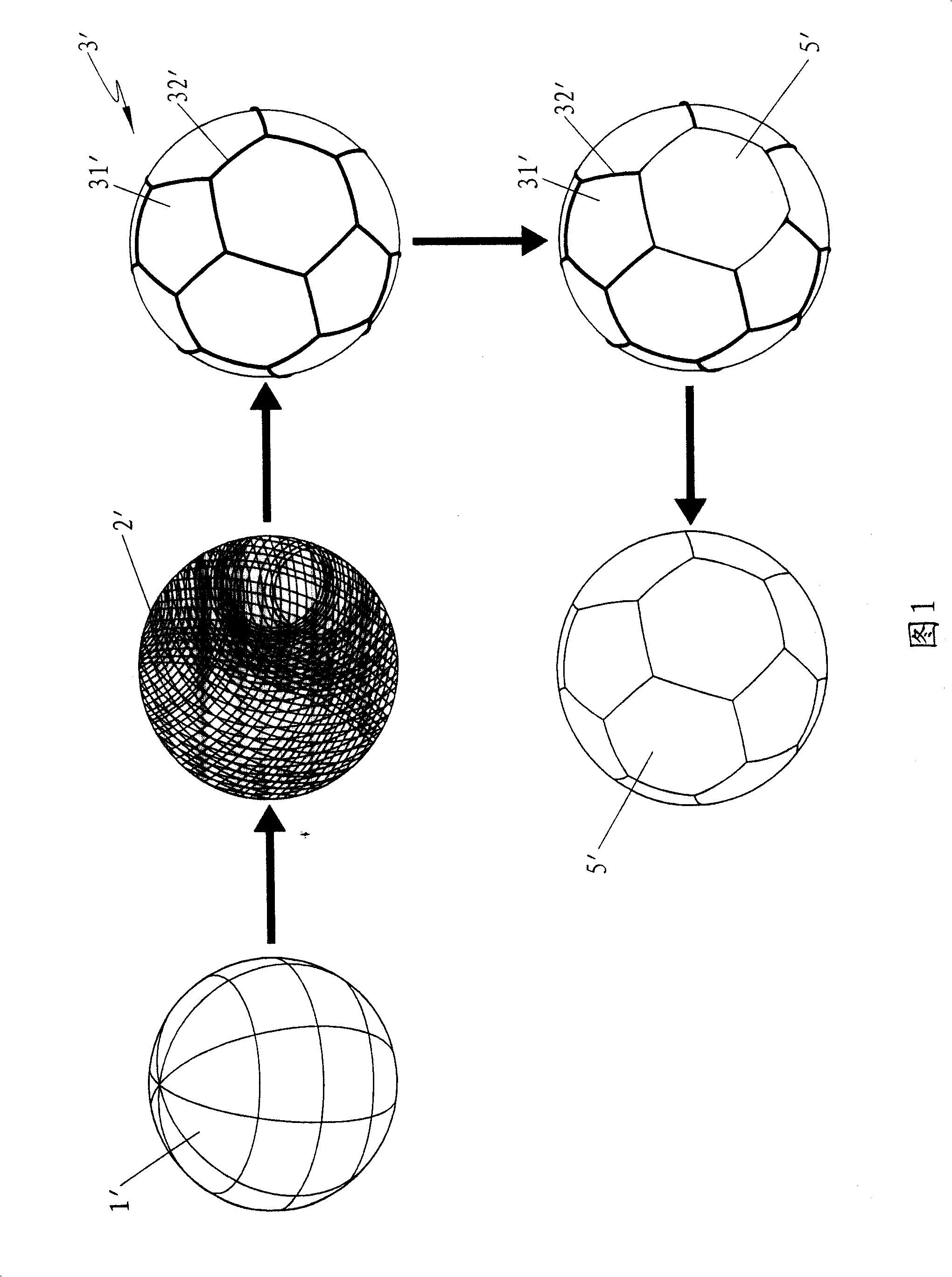

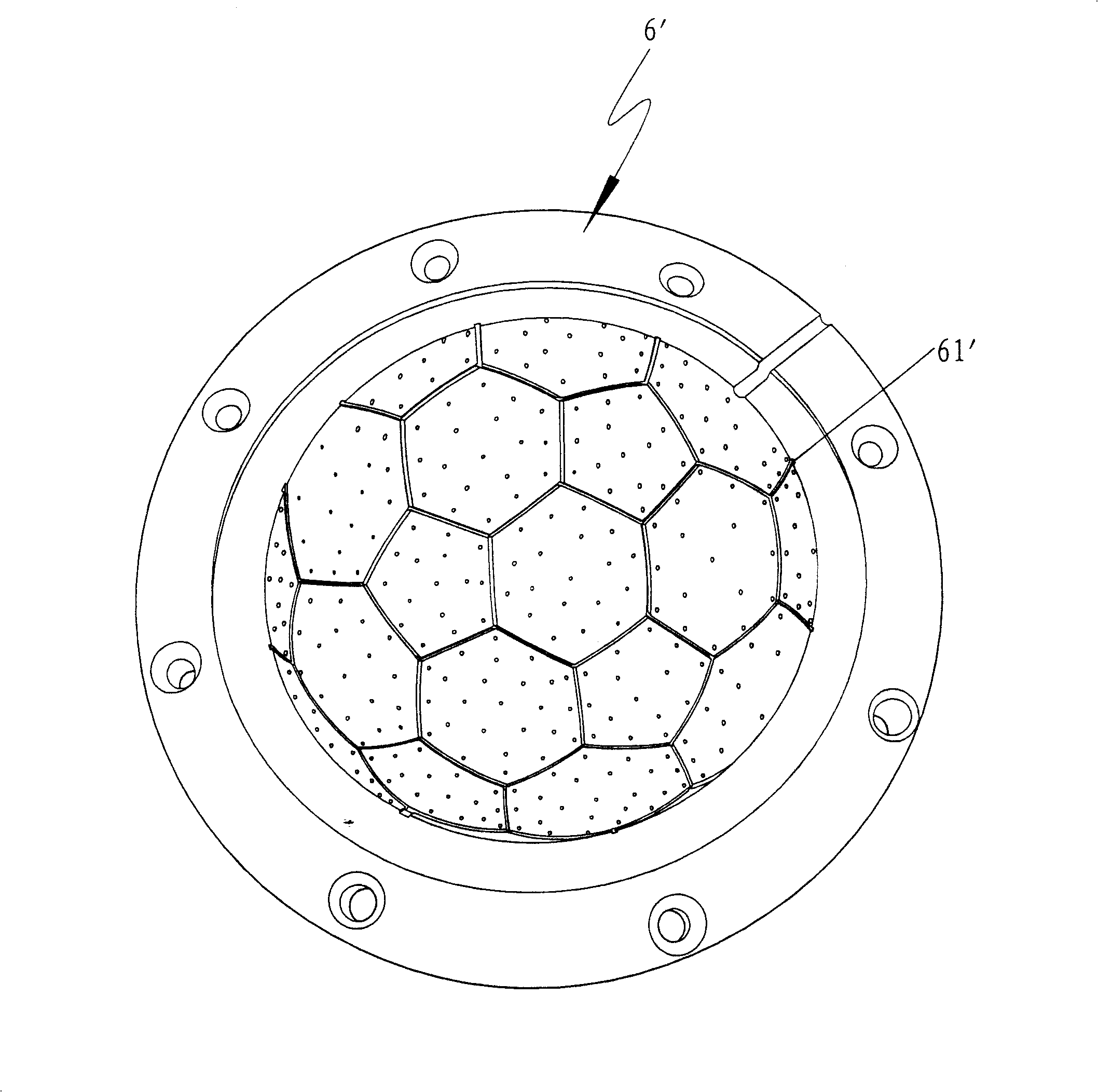

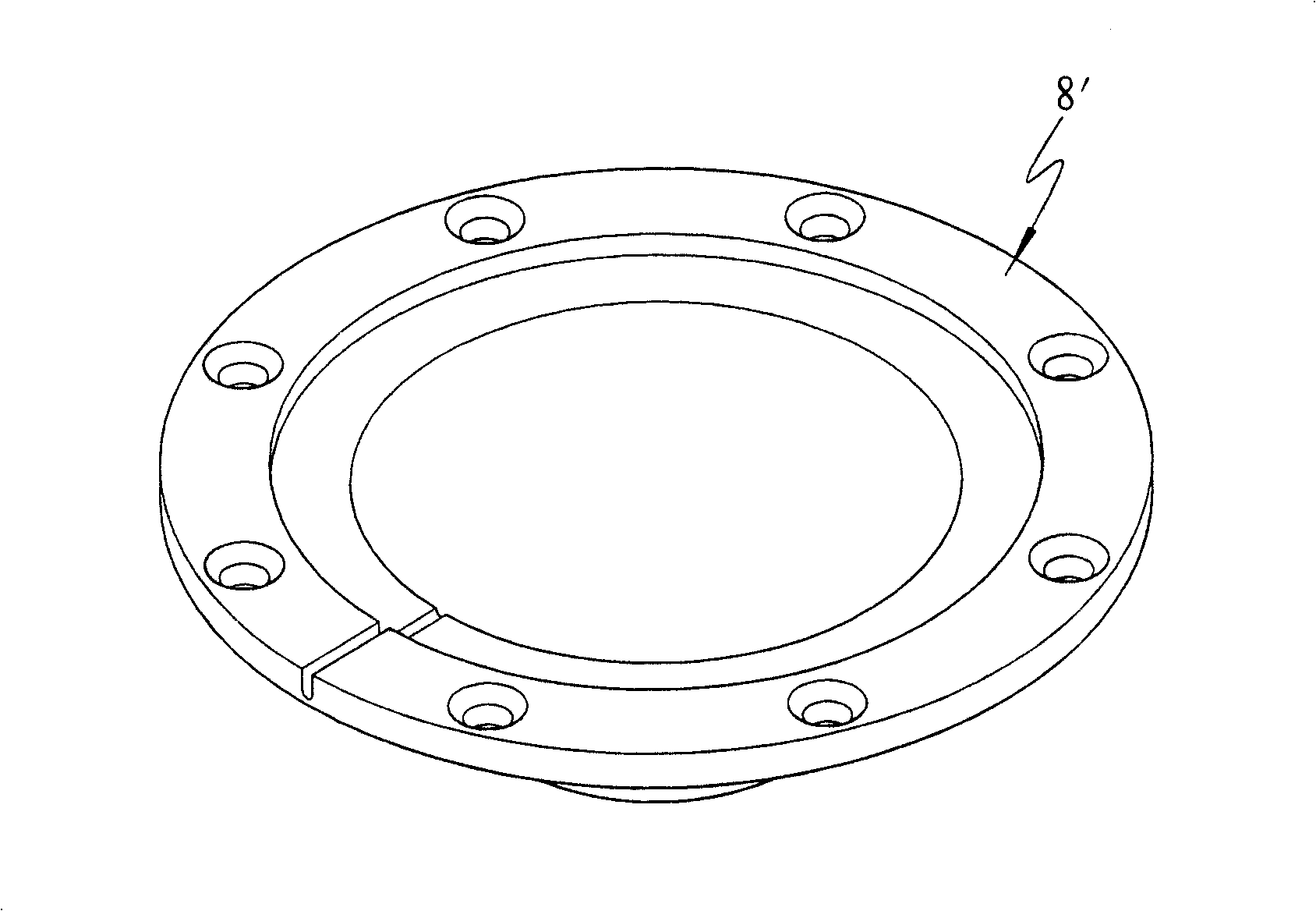

[0033] like Figure 4 As shown in FIG. 9 and FIG. 10 , the production process of the rubber ball of the present invention mainly includes: making inner tube→wrapping silk→forming middle tire→gluing→applying skin→printing. in:

[0034] (1) Making the inner tube:

[0035] The inner tube 1 can be made of rubber material with high elasticity and good air tightness, so that the inner tube made has excellent bounce and excellent air tightness, thereby realizing that the finished ball also has excellent elasticity and superior air tightness. Tightness.

[0036] (2) Wrapped silk:

[0037] Wrap uniform yarn on the outside of the inner tube 1 that has been made to form a silk wrapping layer 2, so that the middle tube and the finished ball with skin have a stable and fixed range of circumference and excellent roundness, and at the same time it has high durability. The impact strength also enhances the bounce of the mid-tyre. And be coated with viscose glue on the yarn, it not only c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com