Automatic shape inspection apparatus

An appearance inspection device and automatic technology, applied in the direction of measuring devices, installations, instruments, etc., can solve problems such as limiting the rotation range, shortening the life of cables, and degrading the freedom of camera magnification, so as to achieve the goal of not losing freedom and extending life Effect

Inactive Publication Date: 2010-11-10

TORAY ENG CO LTD

View PDF1 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

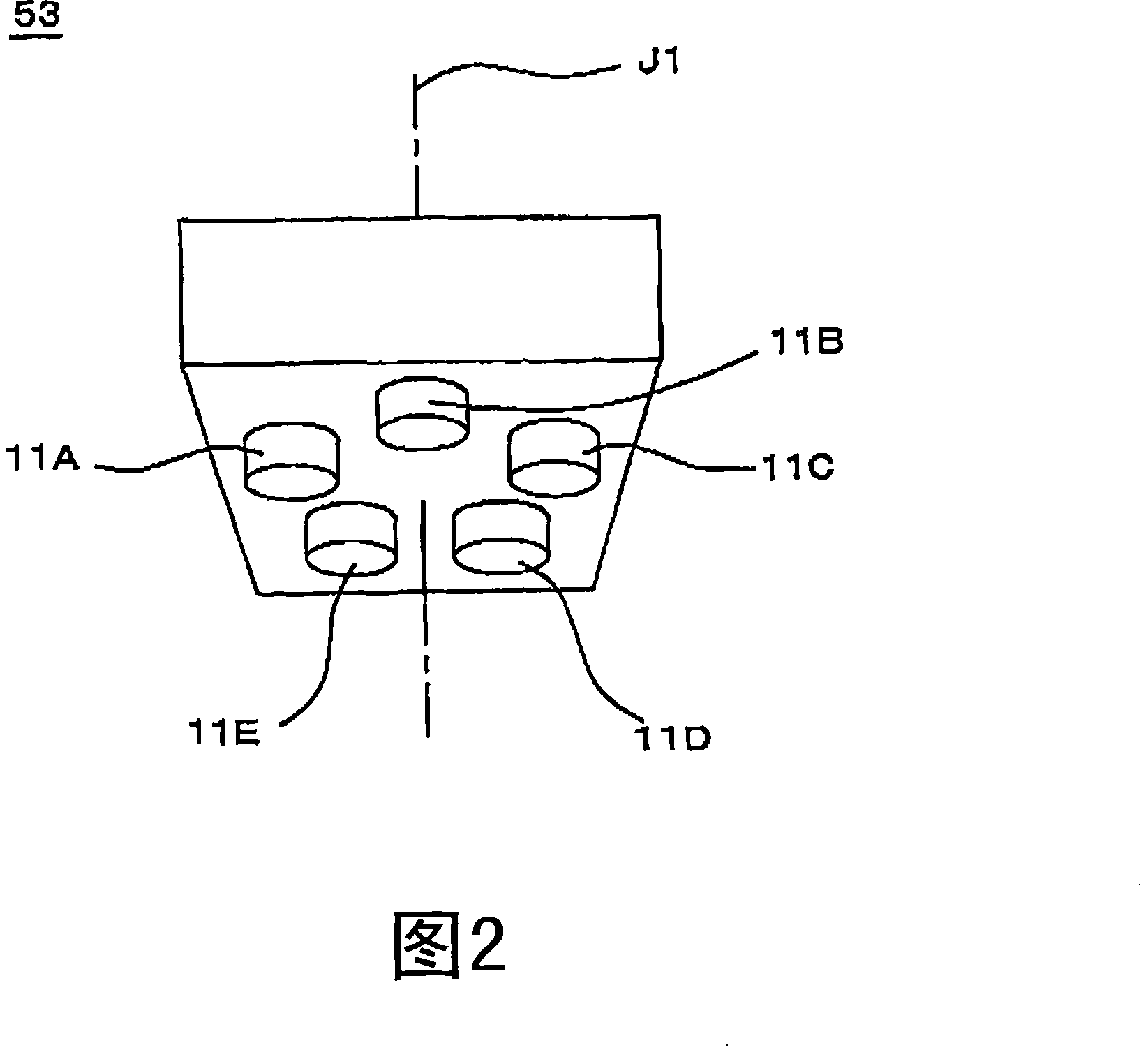

In other words, one objective lens 11 that should be present is reduced by one, and the function is naturally deteriorated at the point of reducing the freedom of imaging magnification.

Furthermore, since the cable 136 for taking out the signal from the displacement sensor 12 to the outside in the automatic appearance inspection device 1A moves together with the converter 53A, the rotation of the converter 53A twists the cable, resulting in shortening the life of the cable.

In addition, the converter 53A itself may rotate more than 360° in a certain direction, but it is limited by the existence of the cable of the displacement sensor 12, which limits its range of rotation.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

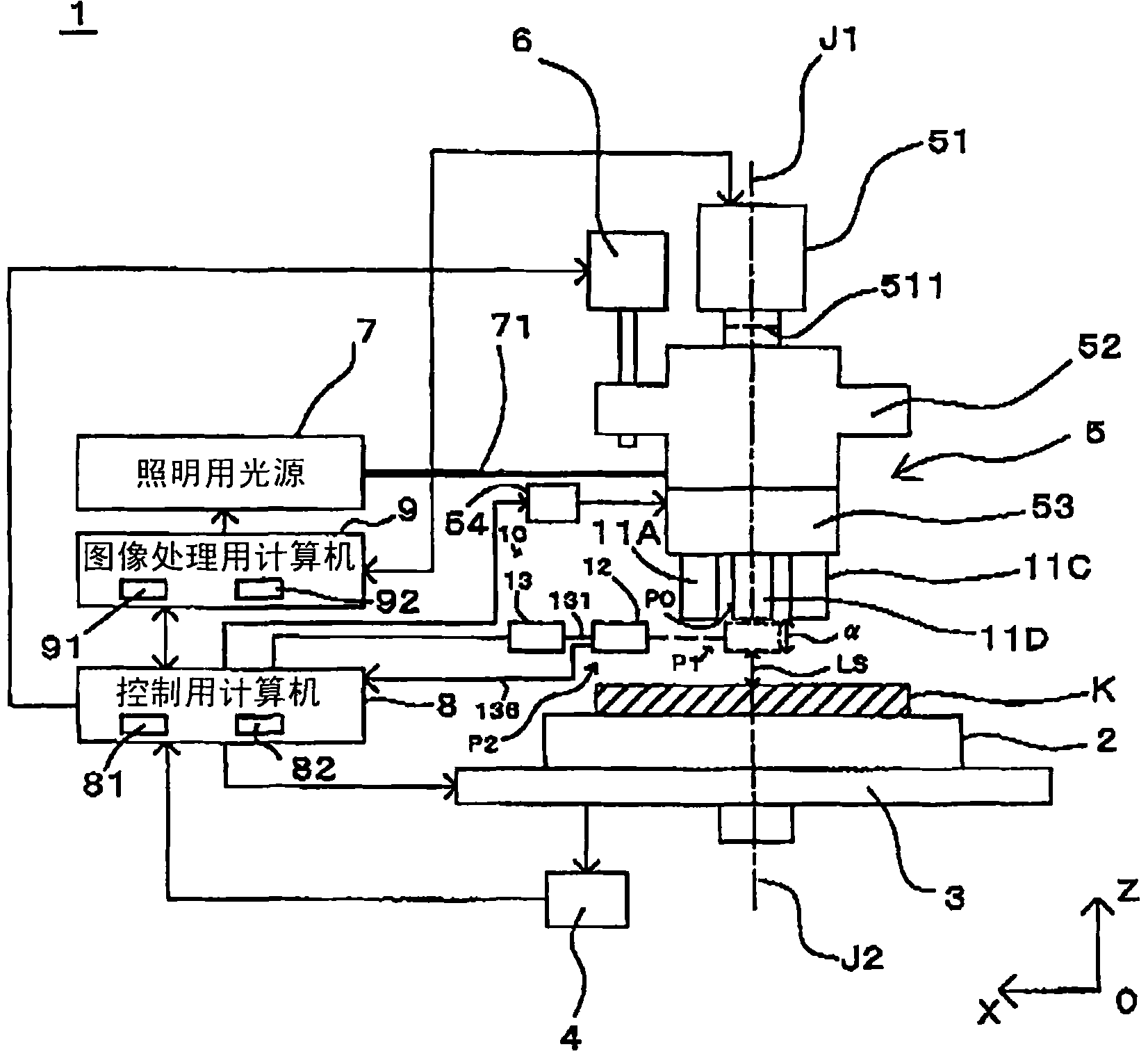

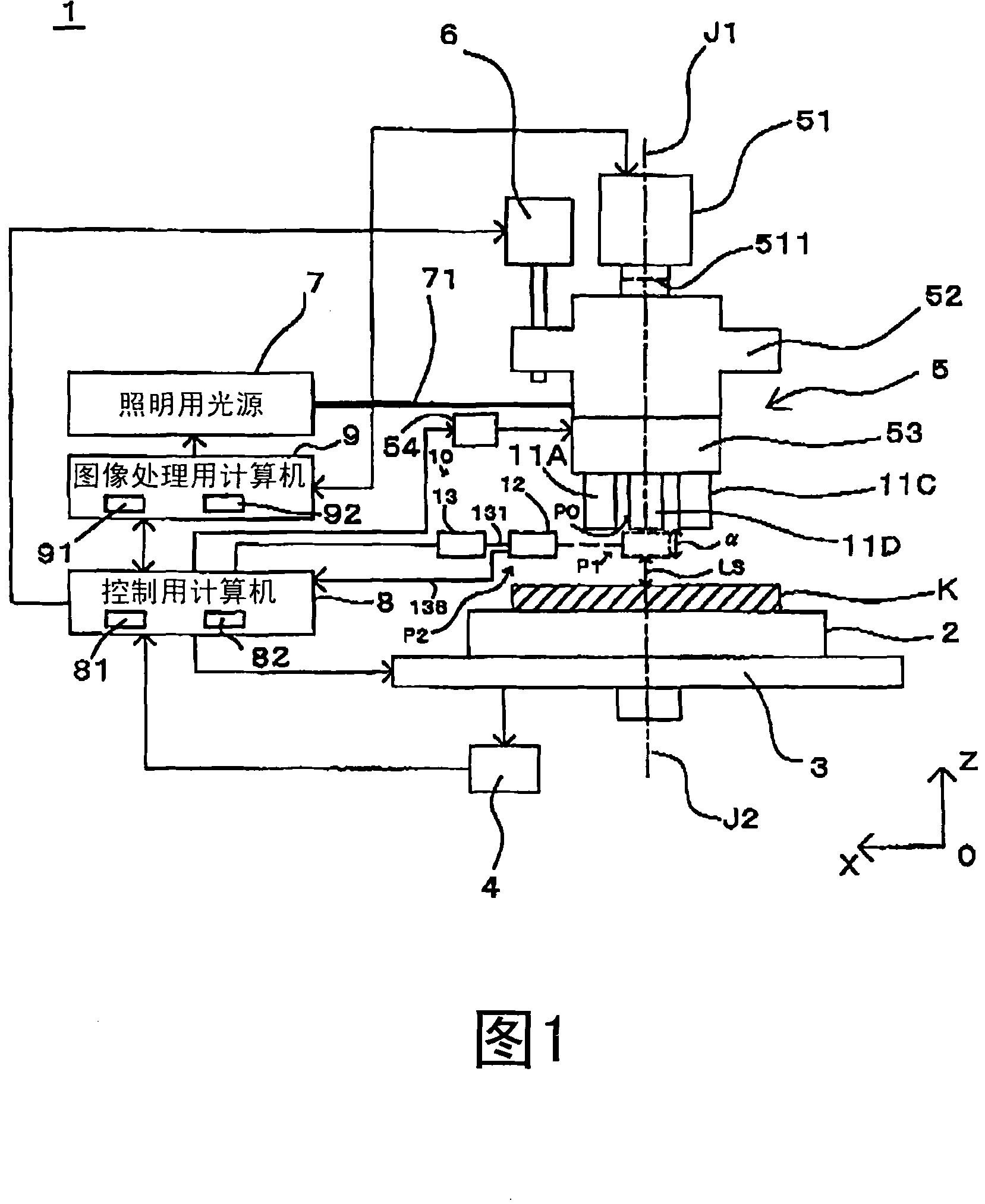

The invention provides an automatic appearance inspection device without losing the freedom of the photographic scaling factor and free of the restrain of the converter action caused by the existence of the sensor cable. The automatic appearance inspection device for automatic focusing before inspecting the appearance of the object work pieces (K) includes: a converter (53) keeping a plurality ofobject lens (11) and selecting one object lens used for inspection; a photographic unit (51) for photographing the image obtained by the selected object lens; a displacement sensor advance and retreat unit (13) leading the displacement sensor (12) to advance and retreat between the selected object lens and the object work pieces; a storing unit (81) for storing the object lens on the reference position (PB) of the object work pieces in advance beat for the focusing displacement as the reference position (LB); and an up and down driving unit (6) making the object lens best for focusing displacement along the up and down direction to drive the converter according to the displacement (LS) of the object work pieces measured by the displacement sensor and the reference displacement stored in the storing unit.

Description

Automatic Appearance Inspection Device technical field The invention relates to an automatic appearance inspection device. In particular, it relates to an automatic appearance inspection device configured to automatically focus before imaging the appearance of a workpiece to be inspected. Background technique In the manufacturing process of semiconductors or FPDs (FlatPanelDisplays, flat panel displays), it is necessary to automatically check whether there are defects such as scratches, spots, peeling, and stains on the patterns formed on silicon wafers or glass plates. Such an automatic appearance inspection device for inspection includes, for example, an imaging unit such as a metallographic microscope and a CCD camera, an image processing device, and the like. The magnified image of the pattern obtained by the metallographic microscope is captured by an imaging unit and converted into image data. The image arithmetic processing device judges whether the graphics appea...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): G01N21/956

CPCG02B7/09G01N21/8806G01N21/9501G01N21/956G01N21/958G01N2021/8809

Inventor 河崎喜代司

Owner TORAY ENG CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com