Automatic shape inspection apparatus

An appearance inspection device and automatic technology, applied in the direction of measuring devices, installations, instruments, etc., can solve problems such as limiting the rotation range, shortening the life of cables, and deteriorating the freedom of camera magnification, so as to achieve the goal of not losing freedom and extending life Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

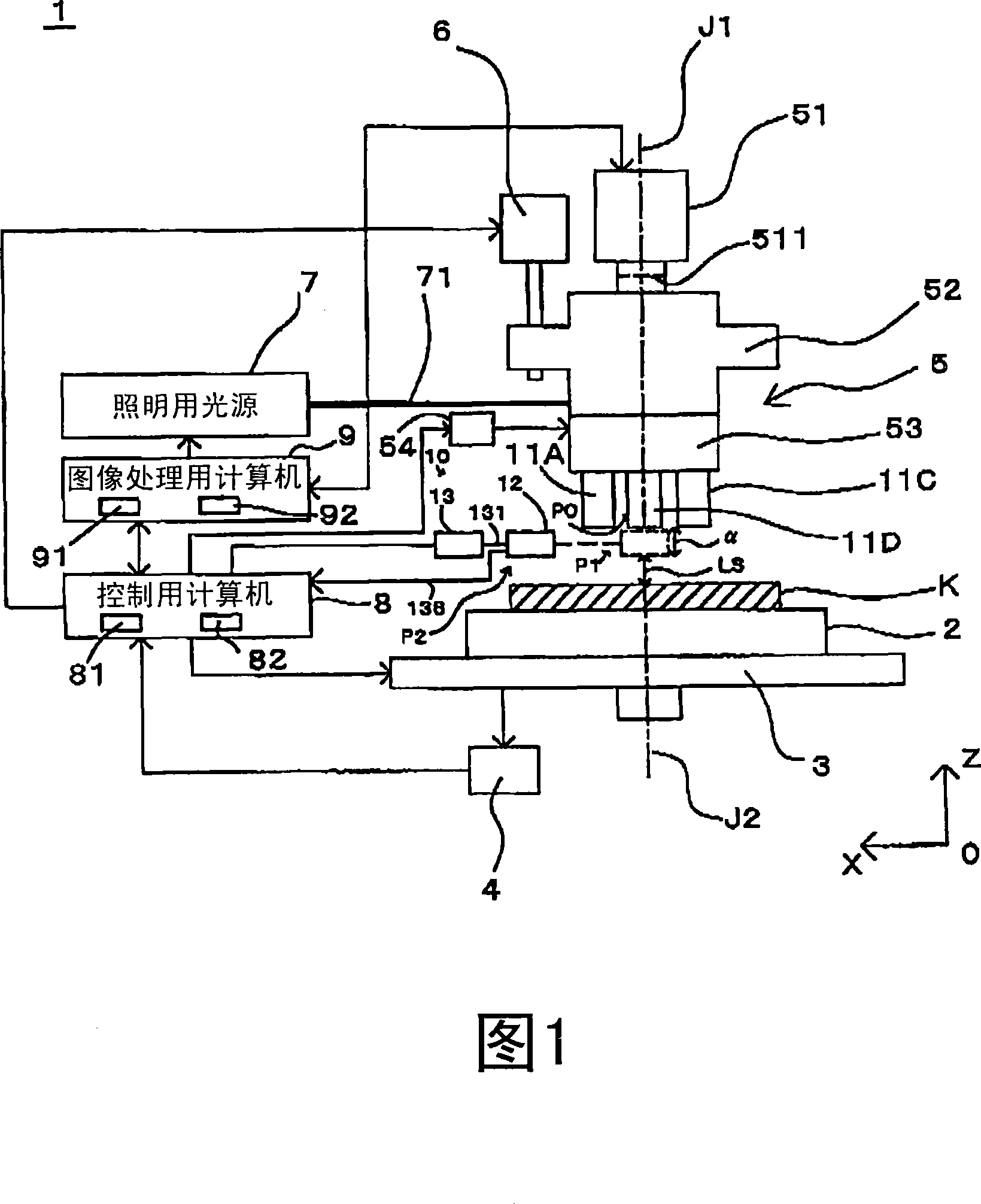

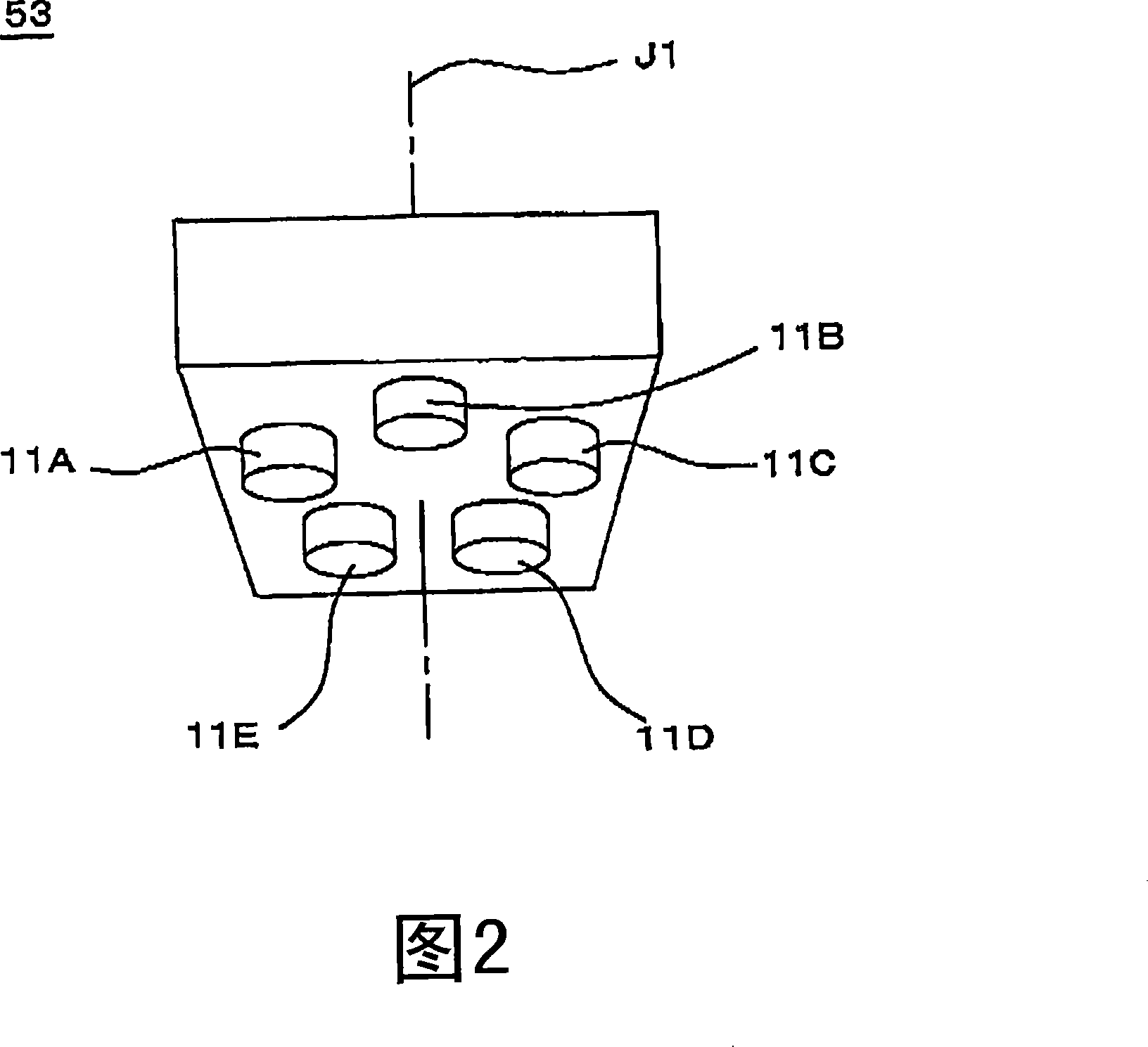

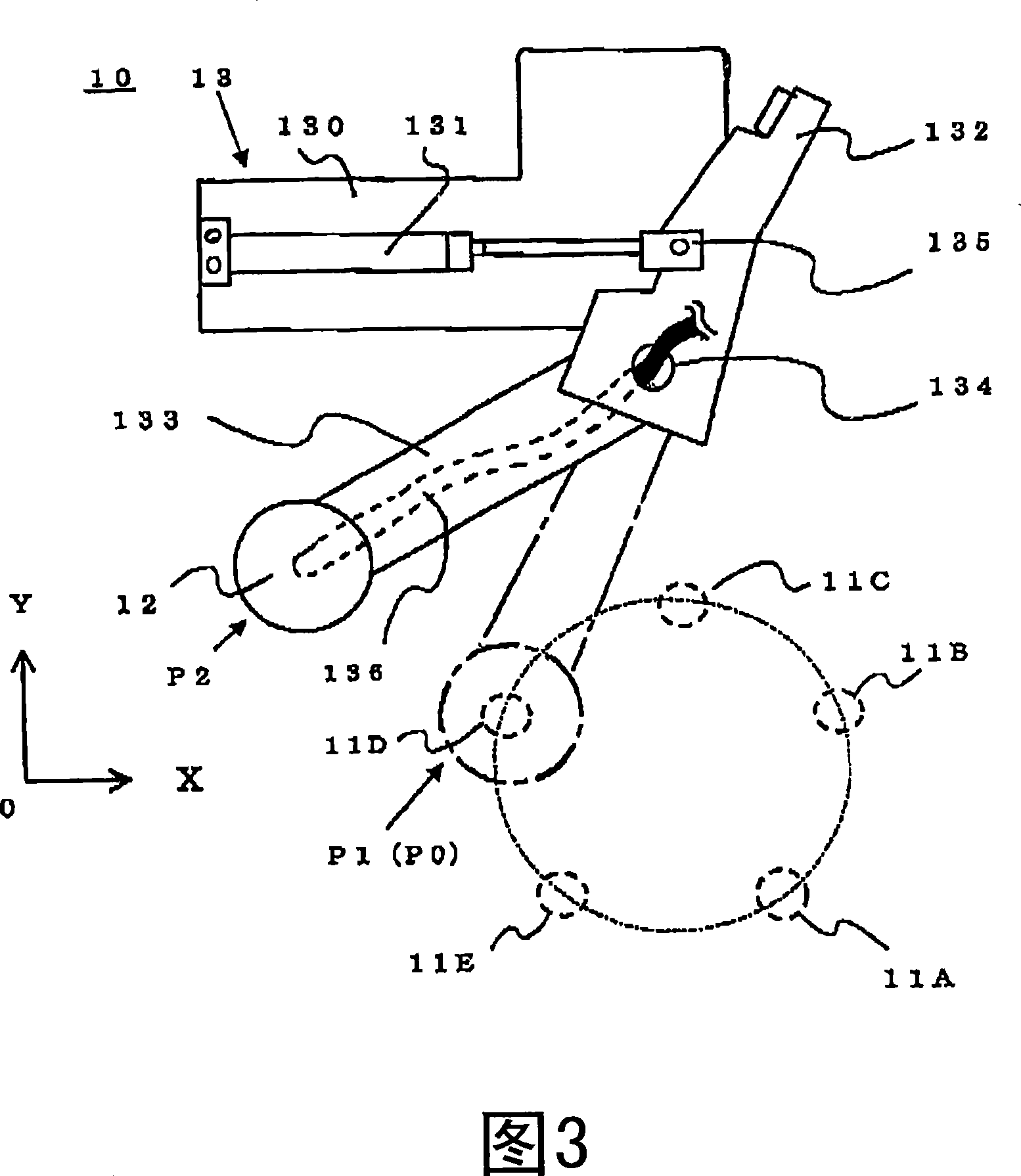

[0023] Preferred modes for carrying out the present invention will be described below with reference to the drawings. 1 is a schematic front view of the automatic visual inspection device 1 of the present invention, FIG. 2 is a perspective view of the appearance of the converter 53, and FIG. 3 is a view of the distance measuring unit 10 viewed from above. In each figure, the three axes of the orthogonal coordinate system are represented as X, Y, and Z, the XY plane is a horizontal plane, and the Z direction is a vertical direction.

[0024] As shown in Figure 1, the automatic appearance inspection device 1 is composed of a workbench 2, an inspection workbench driving unit 3, a position detection unit 4, an imaging optical assembly 5, an imaging optical assembly driving unit 6, a light source 7 for illumination, a distance measuring unit 10, The computer 8 for control, the computer 9 for image processing, etc. are comprised.

[0025] The inspection table 2 is a disk-shaped tab...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com