Vehicle roof with at least two cover elements

A technology for covering parts and roofs, which is applied to road vehicles, passenger vehicles, vehicle parts, etc., to achieve the effect of increasing the amount of adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

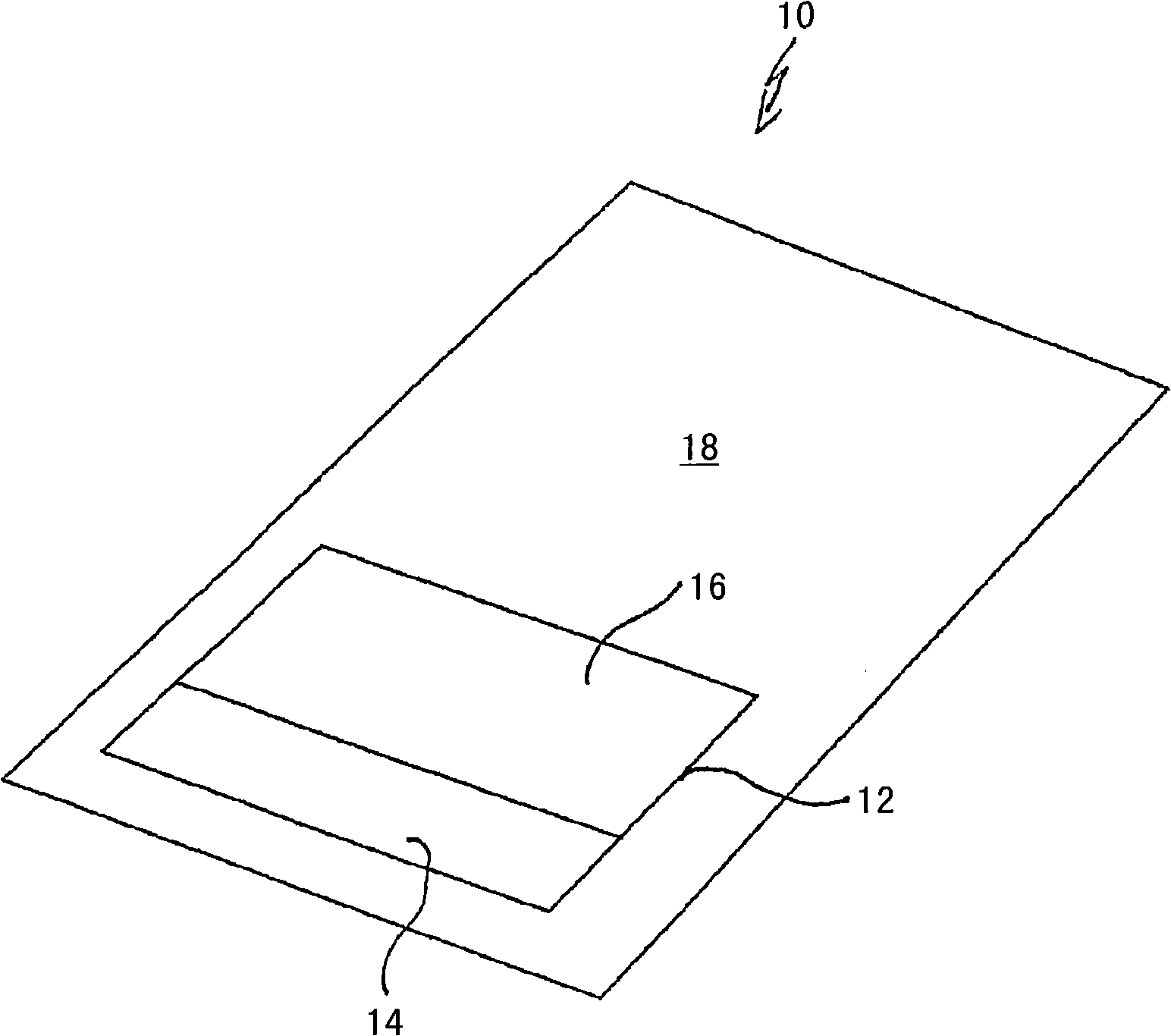

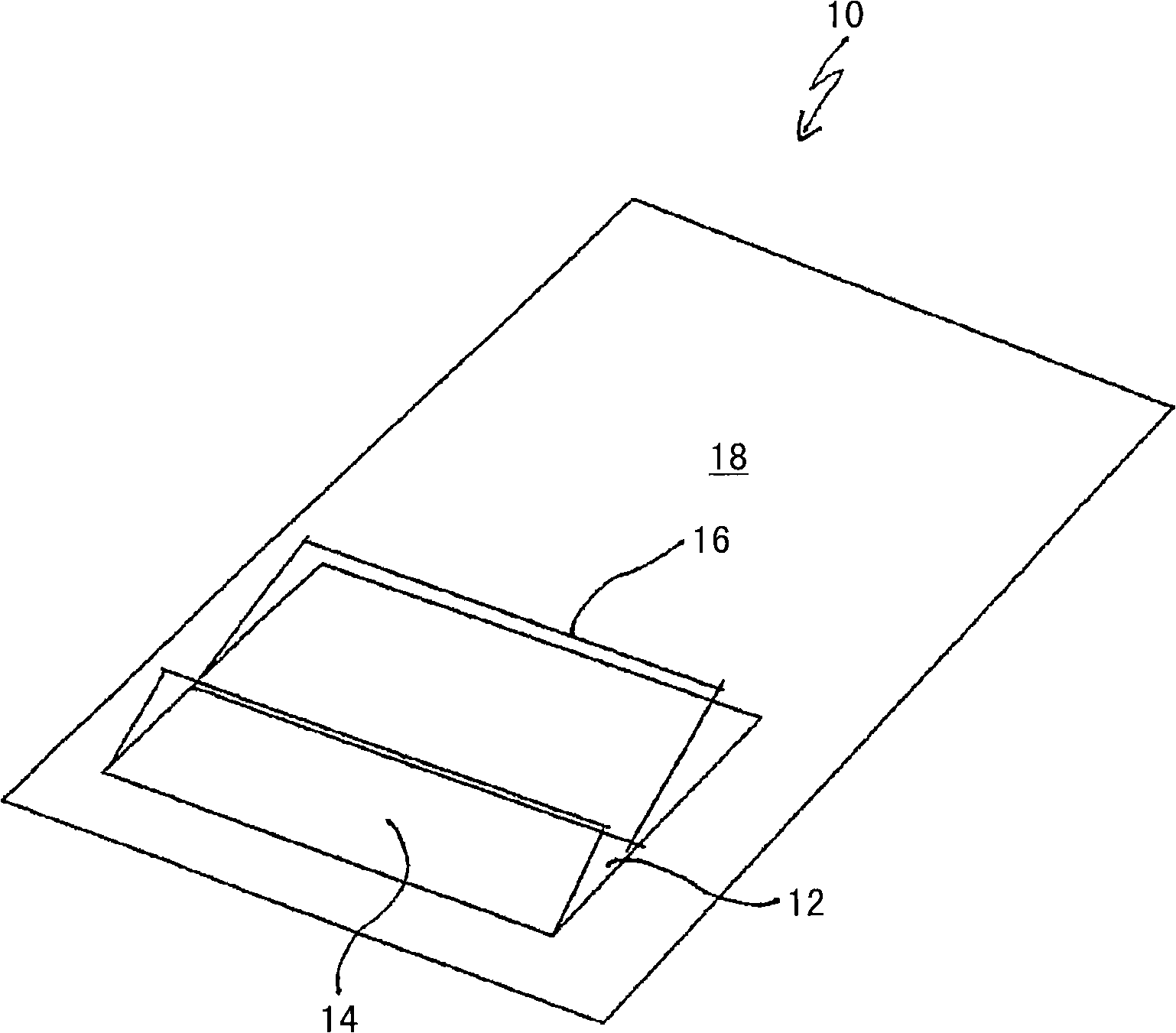

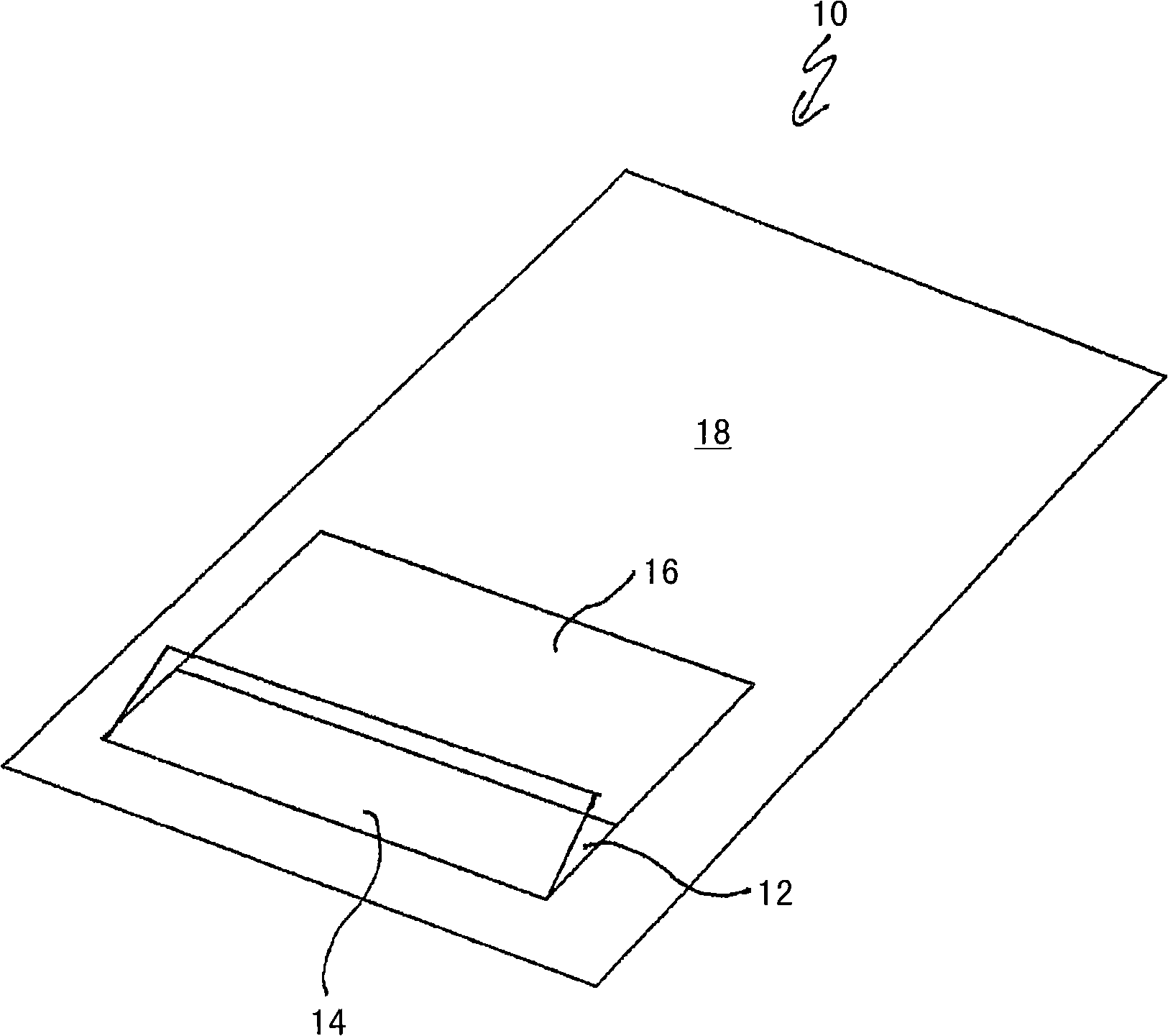

[0042] The drawing shows a vehicle roof 10 with a roof opening 12 which can be closed optionally by means of a cover part 14 located at the front in the direction of travel and a cover part 16 located at the rear in the direction of travel Or at least partially open. In this case, the two cover parts 14 and 16 can assume different positions. From figure 1 Starting from the closed position of the two cover parts 14 and 16 shown, such an arrangement of the two cover parts 14, 16 can be realized, wherein the two cover parts 14, 16 are opened and thus occupy a "ventilation position". ". exist figure 2 This vent position is shown in , which is also known as the dual vent position. Furthermore, an arrangement can be realized in which only the front cover part 14 is opened and thus in the ventilation position, while the rear cover part 16 is closed. exist image 3 This arrangement of the cover parts 14, 16 can be seen in FIG.

[0043] as especially in Figure 4 As can be see...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com