Vertical hammock type air shockproof sleeve

A hammock-style, shock-proof sleeve technology, applied in the direction of preventing mechanical damage, packaging of vulnerable items, containers, etc., can solve the problem of gas packaging bags losing cushioning protection, etc., to achieve the effect of preventing gas leakage and good cushioning protection function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

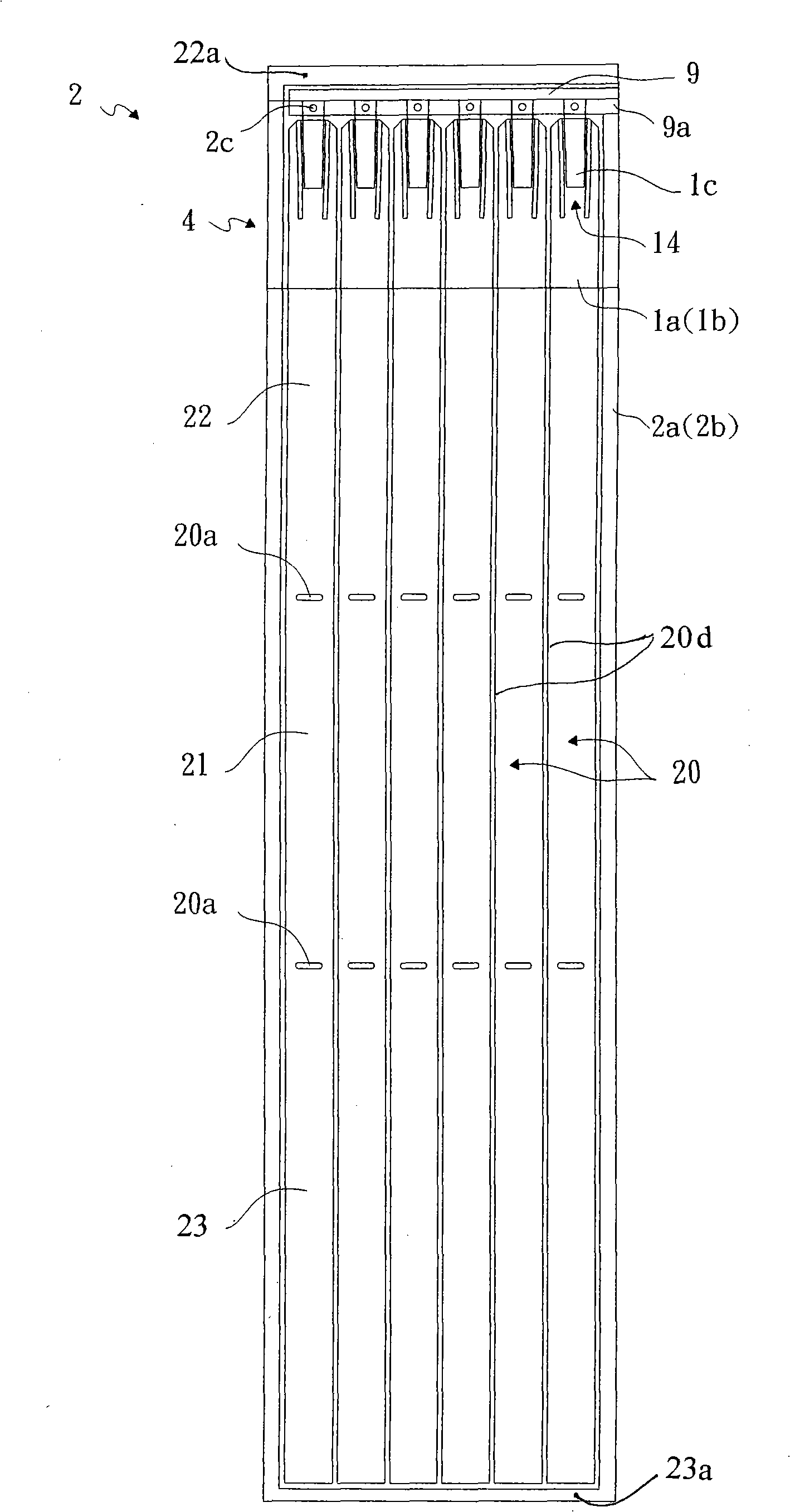

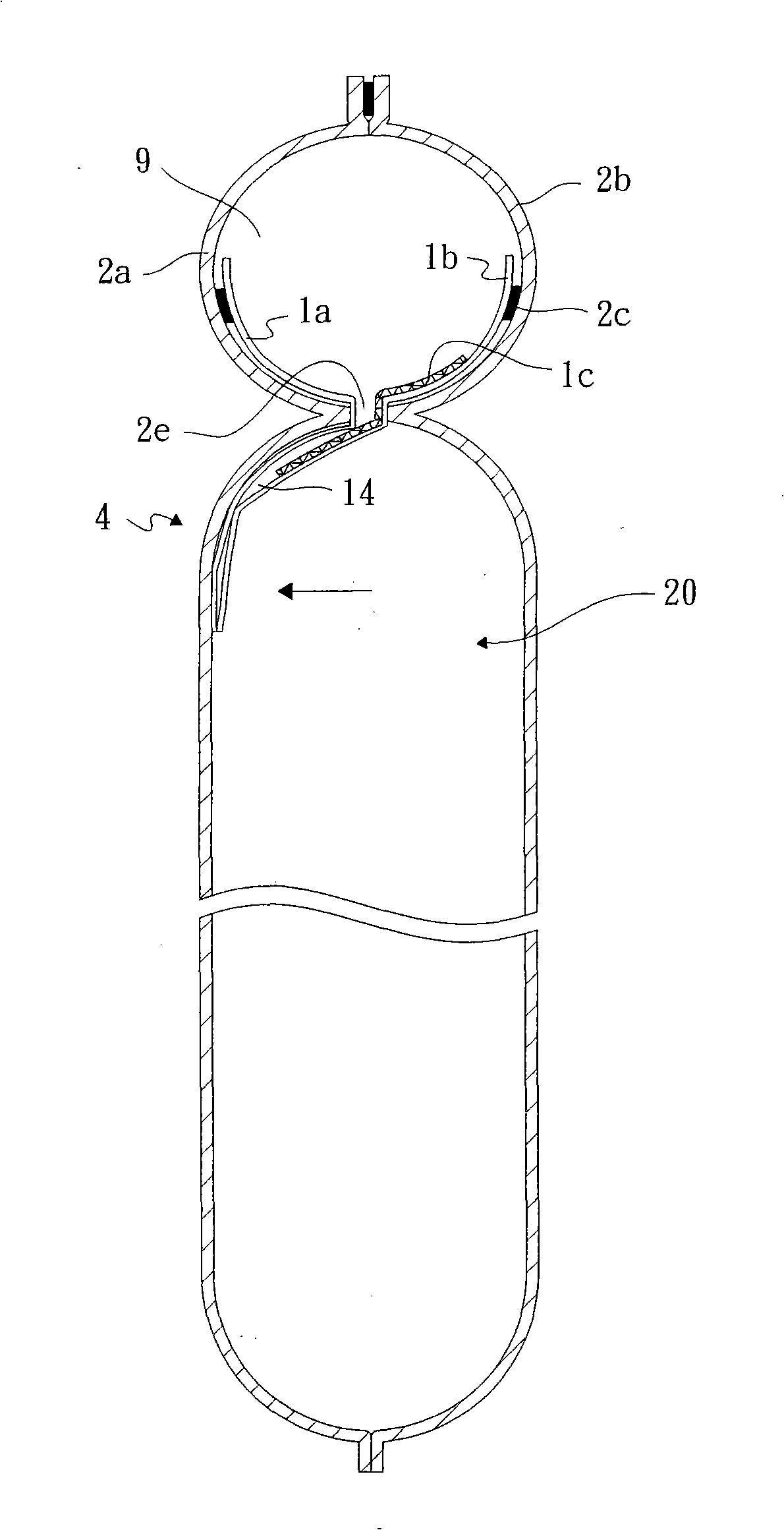

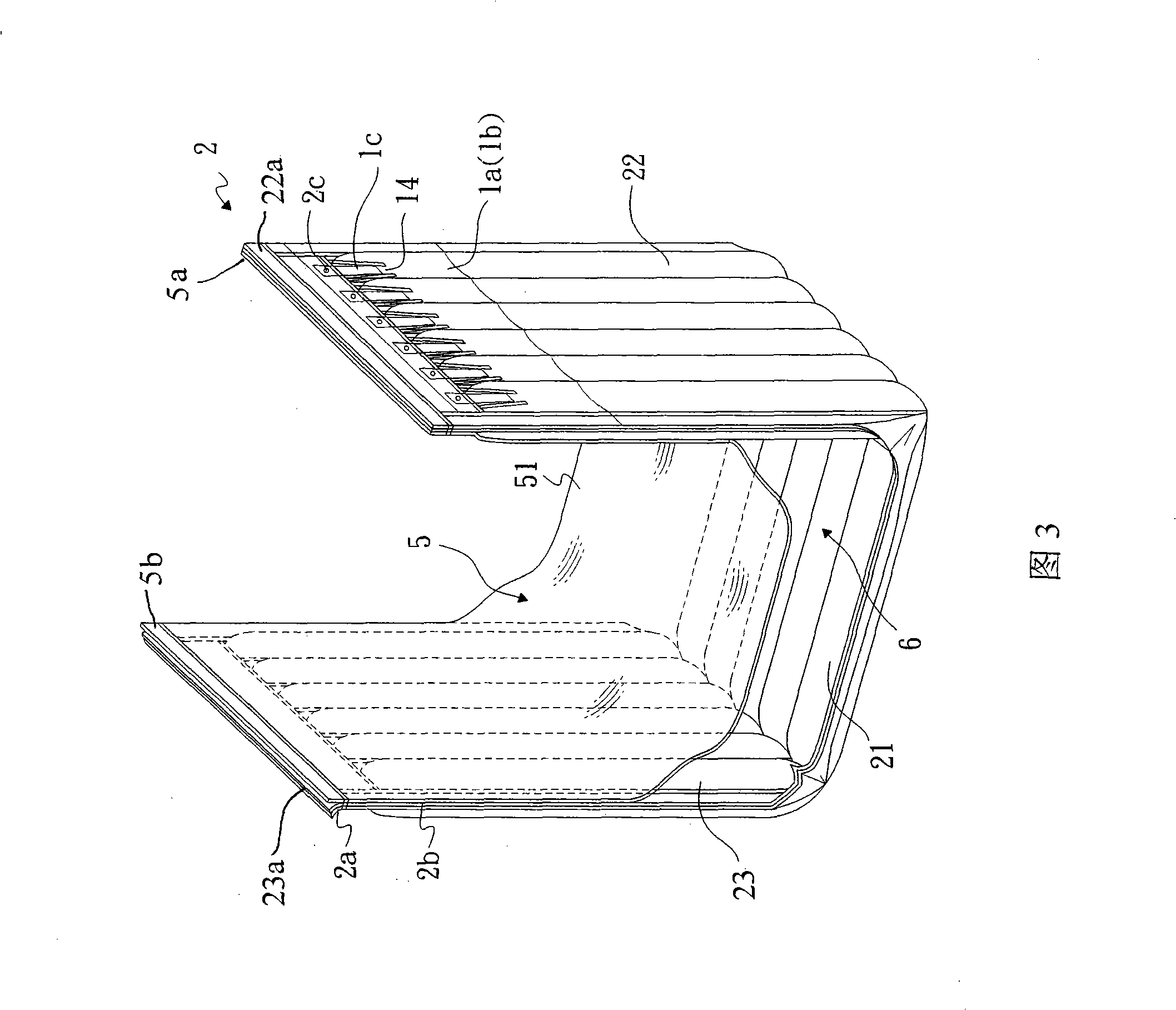

[0043] figure 1 , figure 2 , Fig. 3, Fig. 4A, Fig. 4B and Fig. 4C are the first embodiment of the present invention.

[0044] The upright hammock type air shockproof cover of the present invention comprises: an air column sheet 2 and a buffer sheet 5 .

[0045]The air column sheet is composed of a plurality of air columns 20, wherein the plurality of air columns 20 are formed by heat-sealing and bonding two outer films 2a and 2b, and an air column heat-sealing line 20d is formed between each air column. The outer films 2a and 2b are made of polyethylene (PE), but not limited thereto. In addition, at least two rows of bending nodes 20a are formed on the air column sheet 2, and each bending node is formed by heat-sealing and bonding two outer films 2a and 2b. Each air column 20 is provided with at least two bending nodes 20a. The air columns between the two rows of bending nodes 20 a form the base 21 , and the air columns on both sides of the base 21 respectively form the f...

no. 2 example

[0053] Figure 5 Shown is an upright hammock type air shock boot according to a second embodiment of the present invention. The air column sheet 2 is bent into a U shape along the two rows of bending nodes 20a, and the two sides of the bent air column sheet are heat-sealed and bonded. A plurality of buffer sheets 5 are arranged in the accommodation space 6, and at least two points of the front edge 5a of each buffer sheet 5 are heat-sealed and bonded to the first heat-sealed edge 22a of the air column sheet or heat-sealed between the air columns. On the line 20d, similarly, at least two points of the rear end edge 5b of the buffer sheet 5 are also heat-sealed and bonded to the second heat-sealed edge 23a of the air column sheet or on the heat-sealed line 20d between the air columns, thereby enabling Wrap multiple items 100 at the same time.

no. 3 example

[0055] Figure 6 Shown is an upright hammock type air shock boot according to a third embodiment of the present invention. Wherein, the bearing part 51 of the buffer sheet 5 is suspended in the accommodating space 6 , and the bottom of the bearing part 51 is attached to the air column of the base part 21 . When the article 100 is placed on the bearing part 51, the buffer sheet 5 can slow down the shaking of the article 100 and provide it with the first stage buffer protection, and the base 21 of the air column sheet 2 and the first and second buffer parts 22, 23 can continue to buffer The item 100 is protected, thereby providing a second stage of cushioning protection to the item.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com