Method and device for introducing end of yarn into spinning nozzle of jet spinning machine

A spinning machine and yarn technology, applied in the field of auxiliary devices of jet spinning machines, can solve the problems of slow yarn introduction speed and high complexity, and achieve the effects of reducing cost and improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

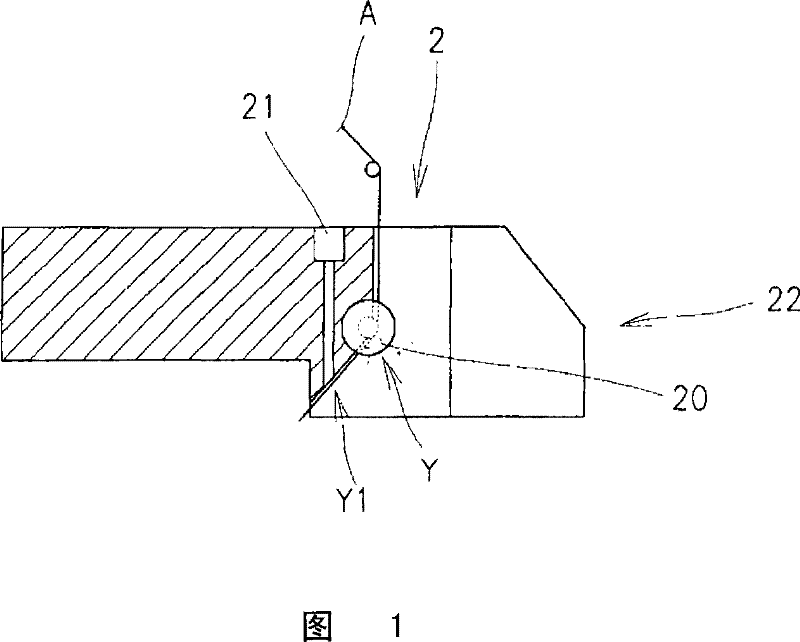

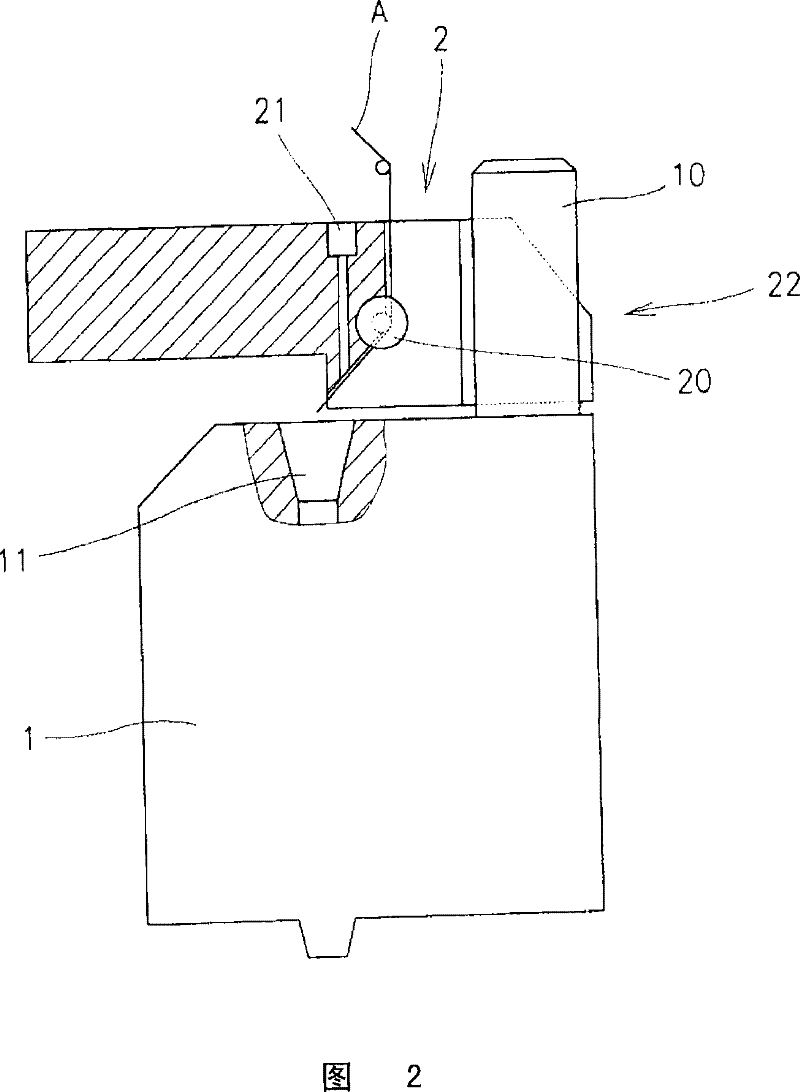

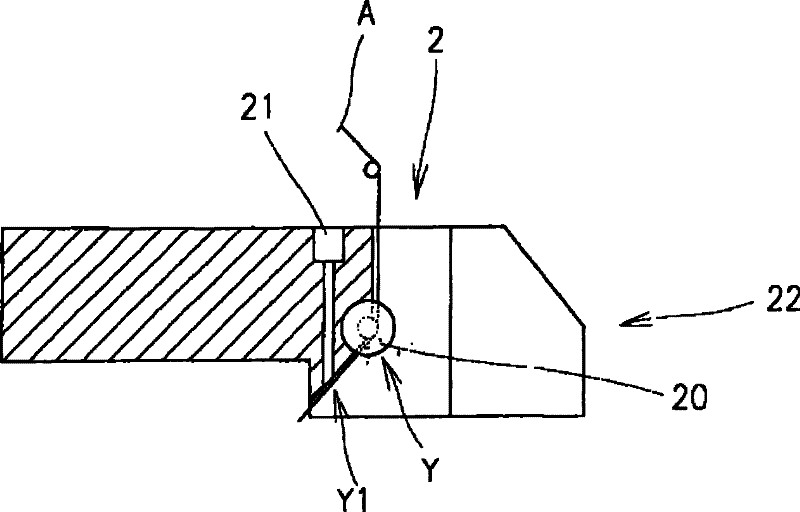

[0021] The method of introducing the end of the yarn A into the spinning nozzle 1 of the jet spinning machine takes place after a spinning interruption, e.g. due to a break of the yarn A in the operating unit or after completing the winding of a bobbin and replacing it with an empty bobbin After the wound bobbin. To resume spinning, use the end of yarn A found on the bobbin (respinning after yarn break) or use the auxiliary yarn on the auxiliary bobbin of the auxiliary device (after the package of a bobbin is completed or when resuming spinning after bobbin replacement).

[0022] The introduction of the end of the yarn A is carried out in such a way that after the interruption of spinning, the auxiliary device first finds the end of the yarn A wound on the bobbin or prepares an auxiliary yarn before the auxiliary device reaches the handling unit. This prepared or found yarn A is guided to the introduction at the part between the bobbin (an auxiliary bobbin or on which the for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com