Method for saving energy through injection air suction in thermodynamic process

A thermal process and thermal energy technology, applied in jet pumps, separation methods, jet propulsion devices, etc., can solve the problems of restricting extensive development, difficult to increase pressure parameters, poor investment cost and efficiency, etc., to simplify the jet device and shorten the jet length. , the effect of avoiding throttling loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0054] Embodiment 1, structure and principle of composite jet pumping:

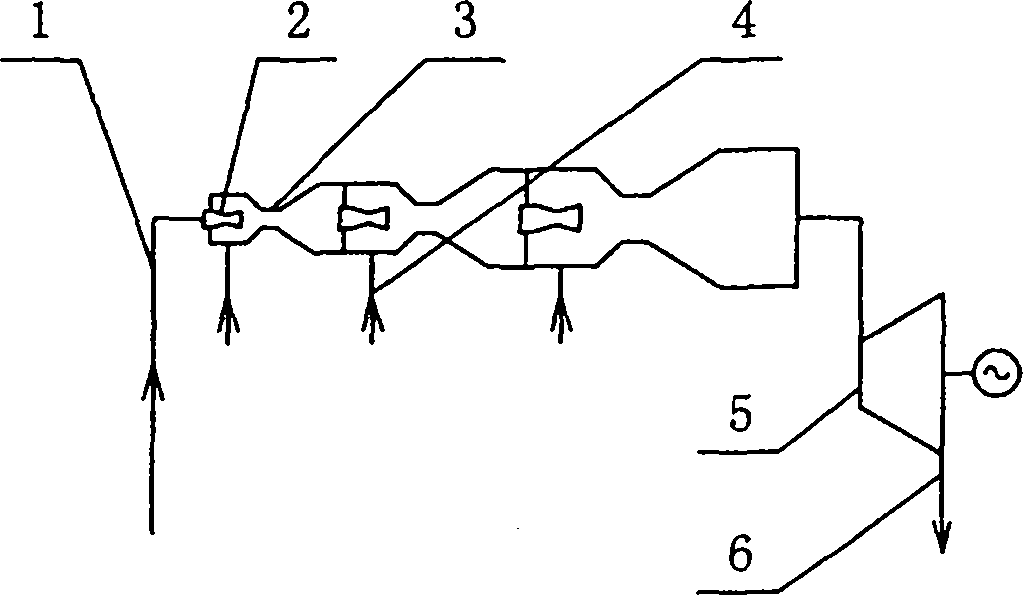

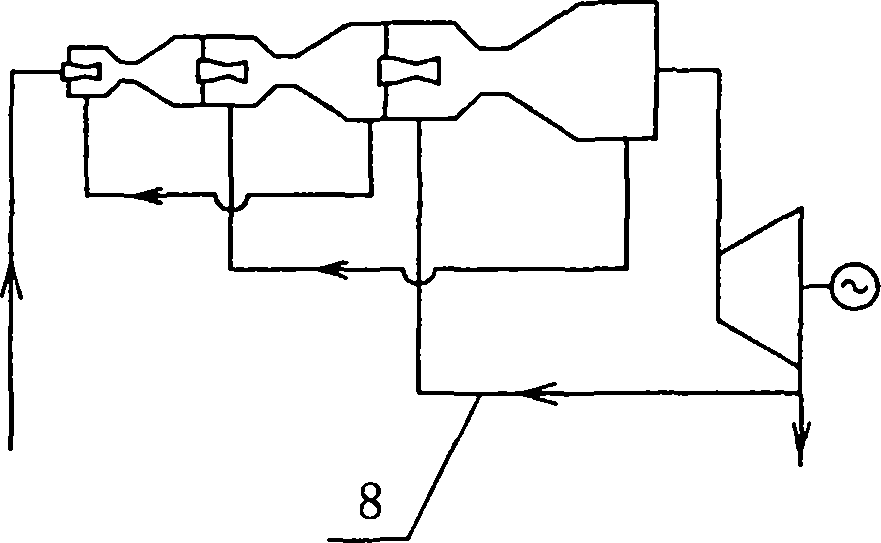

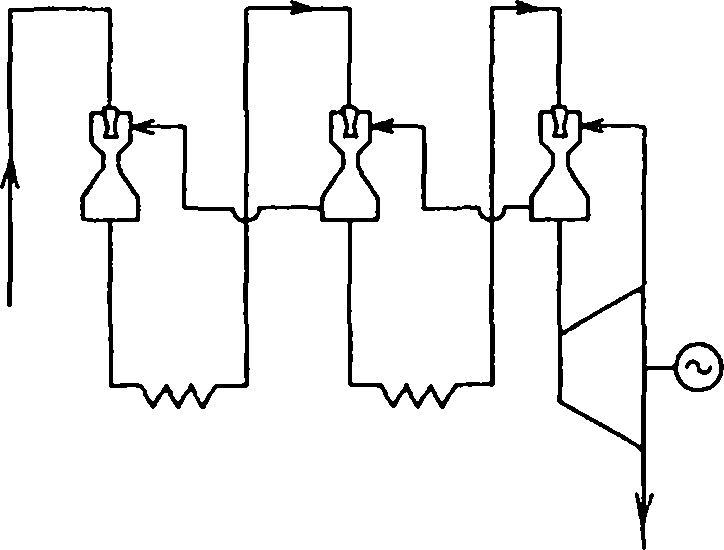

[0055] as attached figure 1 In the three-stage series structure of the jet extractor shown, the high-parameter power source enters the main air inlet of the extractor through the pipeline 1, and after spraying through the nozzle 2, the low-parameter gas source is drawn into the low-parameter gas source through the suction pipeline 4, and then passes through the throat 3 Together enter the deceleration diffuser chamber to complete the first-stage pumping, then enter the second-stage and third-stage pumping process, and finally enter the turbogenerator set 5 to expand and perform work, and then discharge the exhaust gas through the pipeline 6. The arrow in the figure indicates the direction of the air flow. attached figure 2 It is a three-stage series series and adopts a circular jet pumping structure. Each stage extracts the gas source after the mixed and diffused air of the lower stage, and the final st...

Embodiment 2

[0058] Embodiment 2, heat blower:

[0059] as attached Figure 7 The multi-stage cycle compound jet extractor shown is generally used for vacuum extraction, and can also be used for thermal induction or thermal blast when the power source is air or flue gas, especially for large fans, which avoids the need for electric power. Process and wind wheel efficiency loss, can fully play the role of energy saving.

Embodiment 3

[0060] Embodiment 3, jet pumping water source heat pump:

[0061] as attached Figure 8 In the water source heat pump or refrigeration system shown, the composite jet pumping system using hot compressed air as the power source extracts the steam in the raw water tank 17 and then mixes and compresses the steam to condense the heat and increase the temperature. After providing heat for the heat user, the steam in the airflow Further condensed water enters the condensed water tank 19 through air-water separation, air is discharged, and the condensed water is collected and reused. In the raw water tank during operation, a large flow rate is generally required to maintain a stable temperature and liquid level. After the raw water is discharged from the water tank, it can be used for direct cooling or by adding heat exchanger 18 for indirect cooling.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com