Electrical connector with spike protection and method for production of a spike protection for electrical connectors

A technology of electrical connectors and connectors, which is applied to the parts, connections, circuits, etc. of the connection device, and can solve the problems of shrinkage hose damage and non-replacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

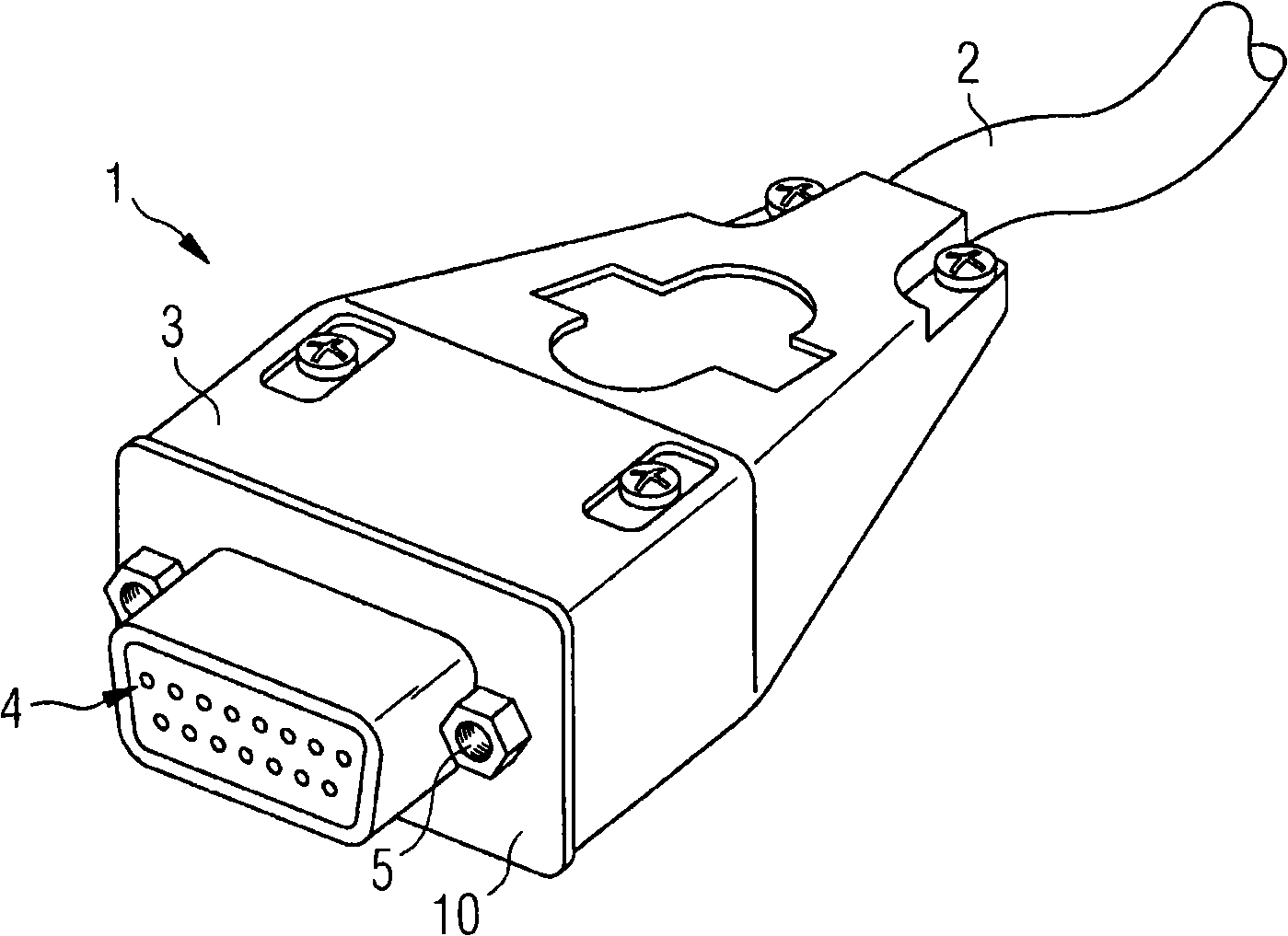

[0027] figure 1 Represents an electrical connector 1 and a cable 2 fixed thereon. The housing 3 of the connector 1 is entirely made of metal. Located on the end side of the connector 1 is a plug-in face 4 which, in the example shown, is a matrix-shaped contact socket. On both sides of the receptacle part of the connector there are threaded holes into which screws provided on the mating plug can be inserted in order to secure the receptacle connection.

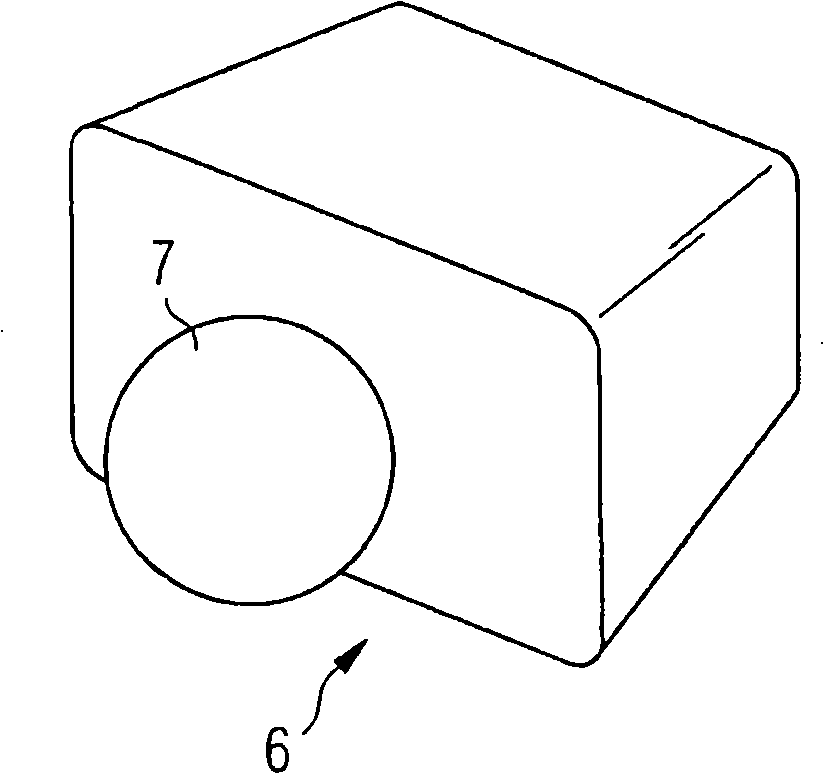

[0028] Figure 2A It shows a perspective view of the insert cover 6 obliquely downward. For easy handling of the plug-in cover, a knob is fixed on its rear side, which makes it easy to remove the plug-in cover from the connector 1 when the shrink hose is put on.

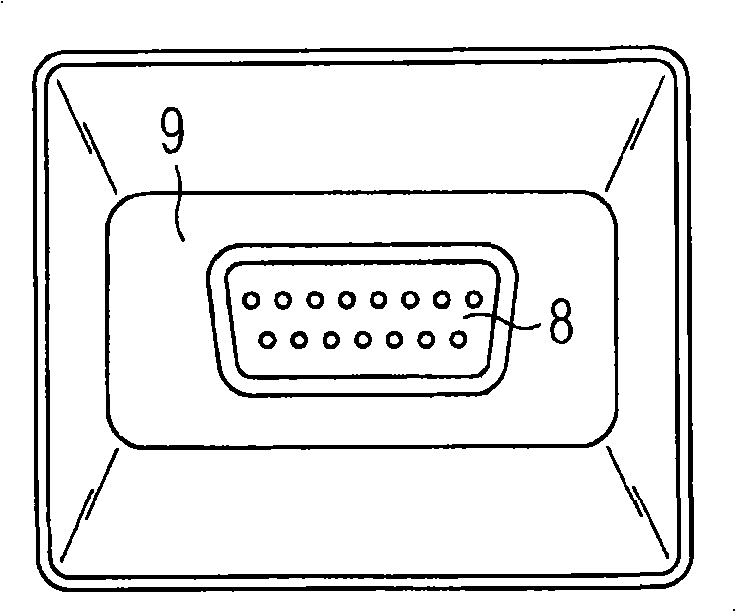

[0029] Figure 2B The front of the insert is shown. The figure shows a plug 8 complementary to the socket 4 with contact pins. However, the plug 8 does not have to be designed to have an effective contact function. Even if it only has a skirt, it is also suffi...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap