Mold for leveling aluminum plate for special-shaped curved face quick former

A special-shaped curved surface and forming machine technology, which is applied in the field of aluminum plate leveling molds and metal sheet metal processing, can solve the problems of high cost, waste of time and effort, and low efficiency, and achieve the effect of smooth surface, small damage, and easy and free forming of workpieces

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] Below the present invention will be further described in conjunction with the embodiment in the accompanying drawing:

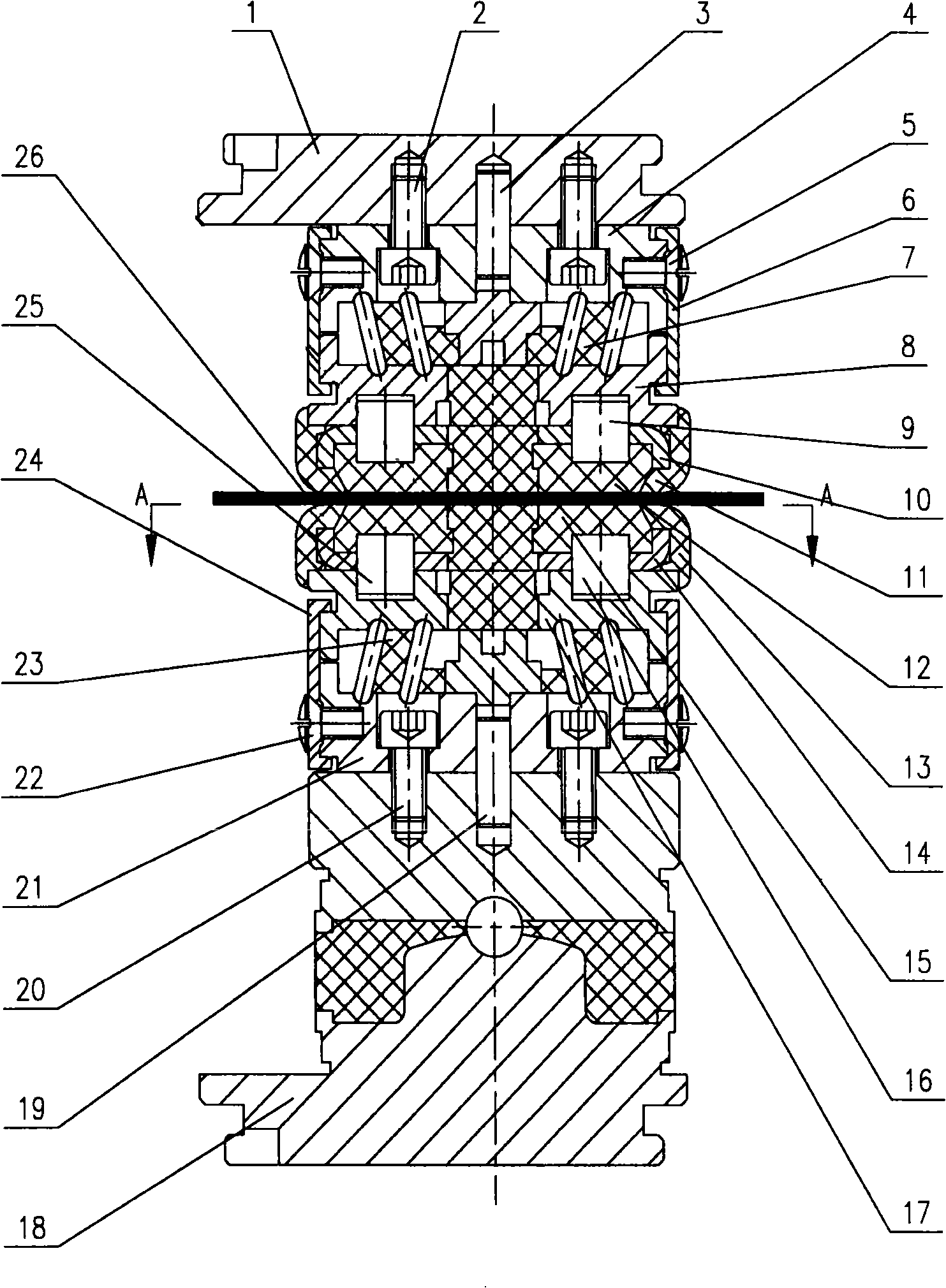

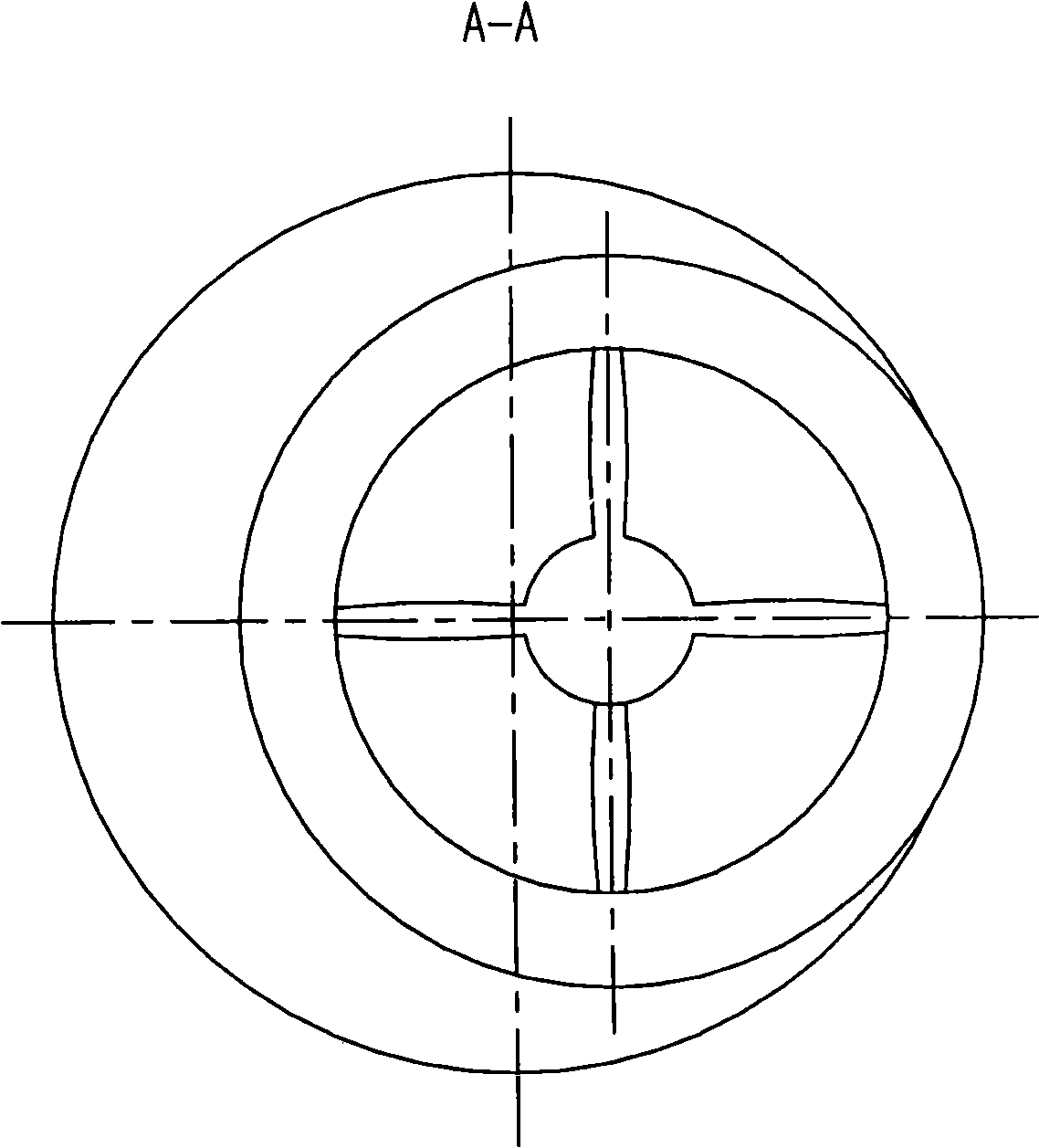

[0011] like figure 1 As shown, the present invention includes upper die connecting seat 1, upper hexagon socket head screw 2, upper die positioning pin 3, upper die force transmission ring seat 4, upper die shield screw 5, upper die shield 6, upper die transmission Force ring 7, upper die connecting plate 8, upper die connecting pin 9, upper die connecting plate 10, upper die rubber sleeve 11, upper die sheet 12, lower die rubber sleeve 13, lower die connecting plate 14, lower die sheet 15, lower die Connecting pin 16, lower mold connecting plate 17, lower mold connecting seat 18, lower mold positioning pin 19, lower hexagon socket head cap screw 20, lower mold power transmission ring seat 21, lower mold shield screw 22, lower mold force transmission ring 23. Lower mold shield 24 and so on.

[0012] The upper die connecting seat 1 and the lower die c...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap