Eccentric chamfering and method of processing the same

A processing method and chamfering technology, applied in metal processing equipment, manufacturing tools, details of milling machine equipment, etc., can solve problems such as incomplete chamfering, and achieve the effect of ensuring the use effect and removing burrs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

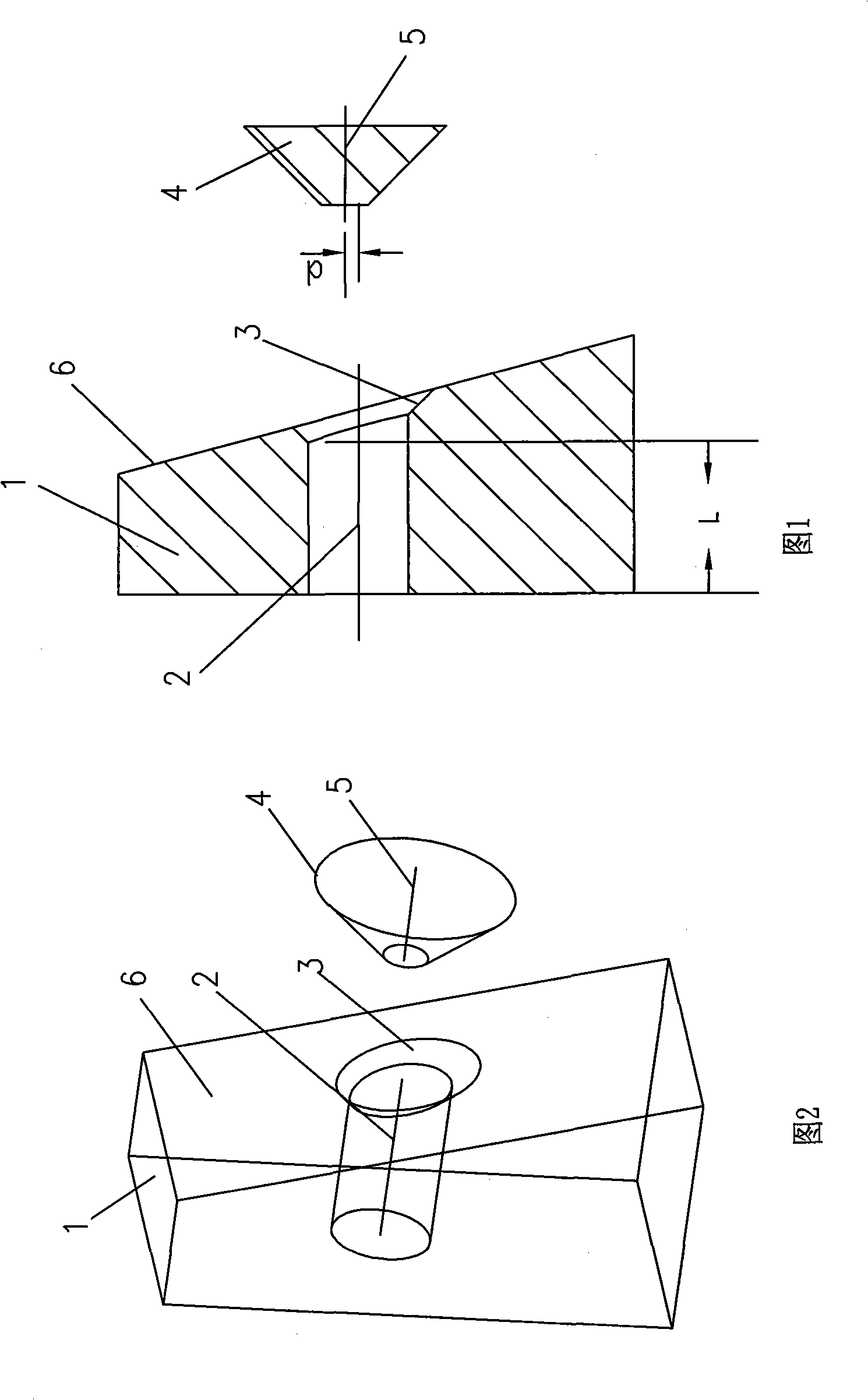

[0021] Referring to Figure 1 and Figure 2, the chamfer on the shaft hole opening on the side of the draft slope 6 on the casting 1 is set as an eccentric chamfer, and the eccentric chamfer is the central axis 5 of the chamfered cone surface and the central axis 2 of the shaft hole. Parallel with eccentricity, it is located on the periphery of the shaft hole, and the chamfer is complete throughout the circumference.

[0022] In specific implementation, the eccentricity is the deviation of the central axis 5 of the chamfered cone surface towards the upper top direction of the casting 1, and the longitudinal section of the casting 1 parallel to the central axis 2 of the shaft hole is a trapezoidal structure with a narrow upper top and a wider lower bottom.

[0023] The amount of eccentricity can also be that the central axis 5 of the chamfered cone deviates toward the upper top direction of the casting 1, and is in the same longitudinal plane as the central axis 2 of the shaft hol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com