Assembled method of electric connector and structure thereof

An assembly method and technology for electrical connectors, applied in the directions of assembly/disassembly of contacts, connection/disconnection of connecting devices, fixation/insulation of contact members, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The assembly method and structure of the electrical connector of the present invention will be further described below with reference to the drawings and specific embodiments.

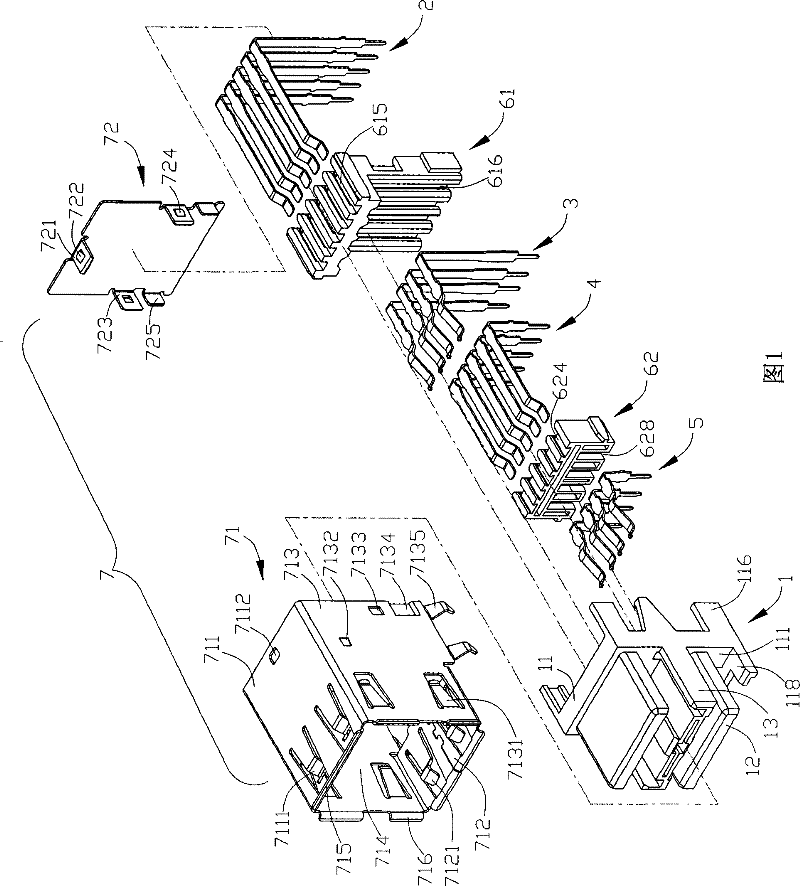

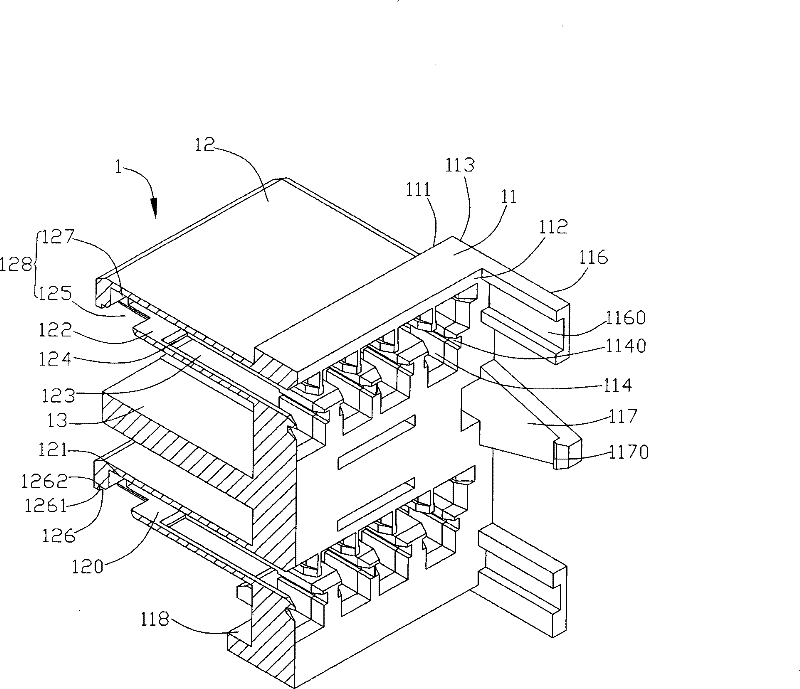

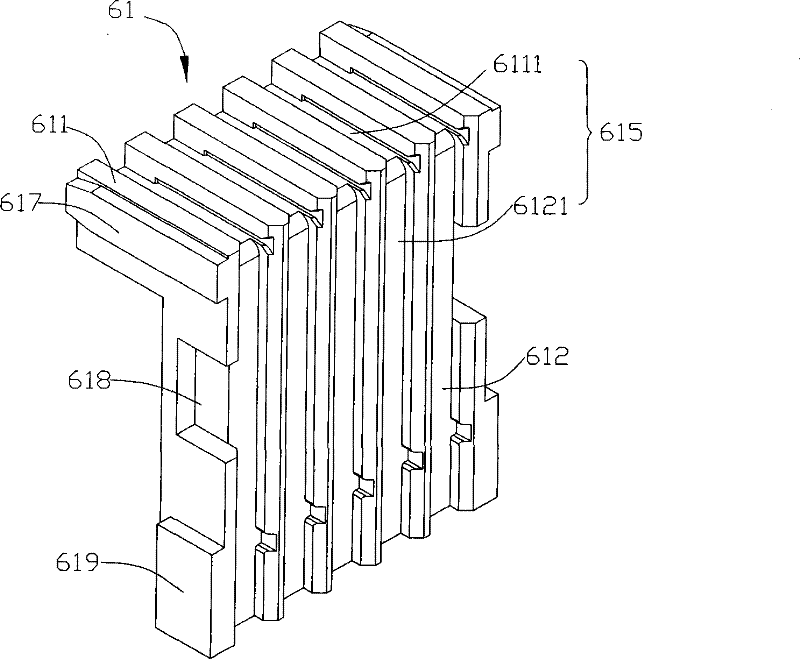

[0021] Please refer to Figure 1 to Figure 11 , the electrical connector in the present invention includes a first body 1, a first conductive terminal group 2, a second conductive terminal group 3, a third conductive terminal group 4, a fourth conductive terminal group 5, two second The main body and a shielding case 7 . Wherein, the second conductive terminal group 3 and the first conductive terminal group 2 are conductive terminals for transmitting signals at two different speeds, and the third conductive terminal group 4 and the first conductive terminal group 2 are the same a kind of conductive terminal, the fourth conductive terminal group 5 and the second conductive terminal group 3 are the same kind of conductive terminals, and the two second bodies are respectively a first rear plug 61 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com