Machine barrel liquid additive agent spray gun device

A liquid additive and additive technology, which is applied in the field of liquid additive spray gun device of twin-screw plastic extruder barrel, can solve the problems affecting the production process, decomposition phenomenon, explosiveness, etc., and achieves remarkable application effect, unique mechanism, and improved The effect of processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

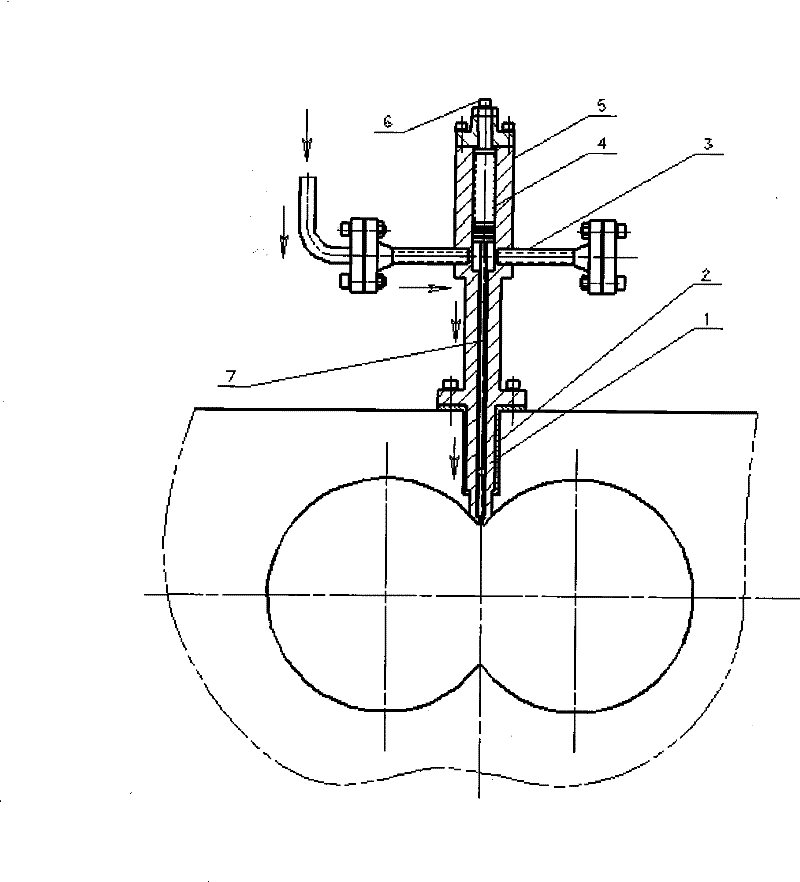

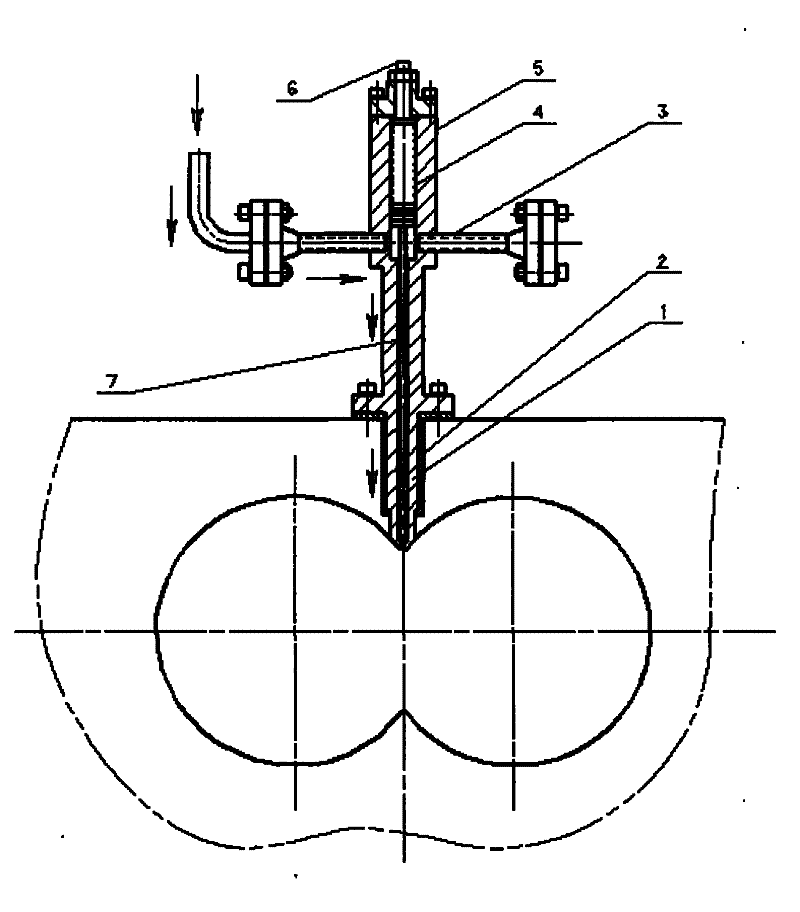

[0009] Such as figure 1 The liquid additive spray gun device shown in the machine barrel liquid additive spray gun device has a piston needle valve installed in the piston body, an adjusting screw 6 is installed at the end of the piston body 5, a spring 4 is installed in the piston body, one end of the spring is connected with the adjusting screw, and the other end is Connected with the piston needle valve 7, the piston body is perpendicular to the piston needle valve with a connecting body 3, the connecting body is connected to the additive hydraulic pump, the connecting sleeve 1 is connected to the connection between the piston body and the machine barrel, and the connecting sleeve is covered with a sheath 2 .

[0010] When working, first determine according to the process conditions to ensure that the additive and the melt do not decompose and paste, punch a hole at a certain position of the machine barrel, install the liquid additive spray gun device of the present inventi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com