Fire arm collimating tool

A technology of sights and light weapons, applied in the field of n-type front sight guards, can solve the problems of low accuracy, difficult repair, increase in volume and weight, etc., and achieve the effect of improving aiming accuracy and saving aiming time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

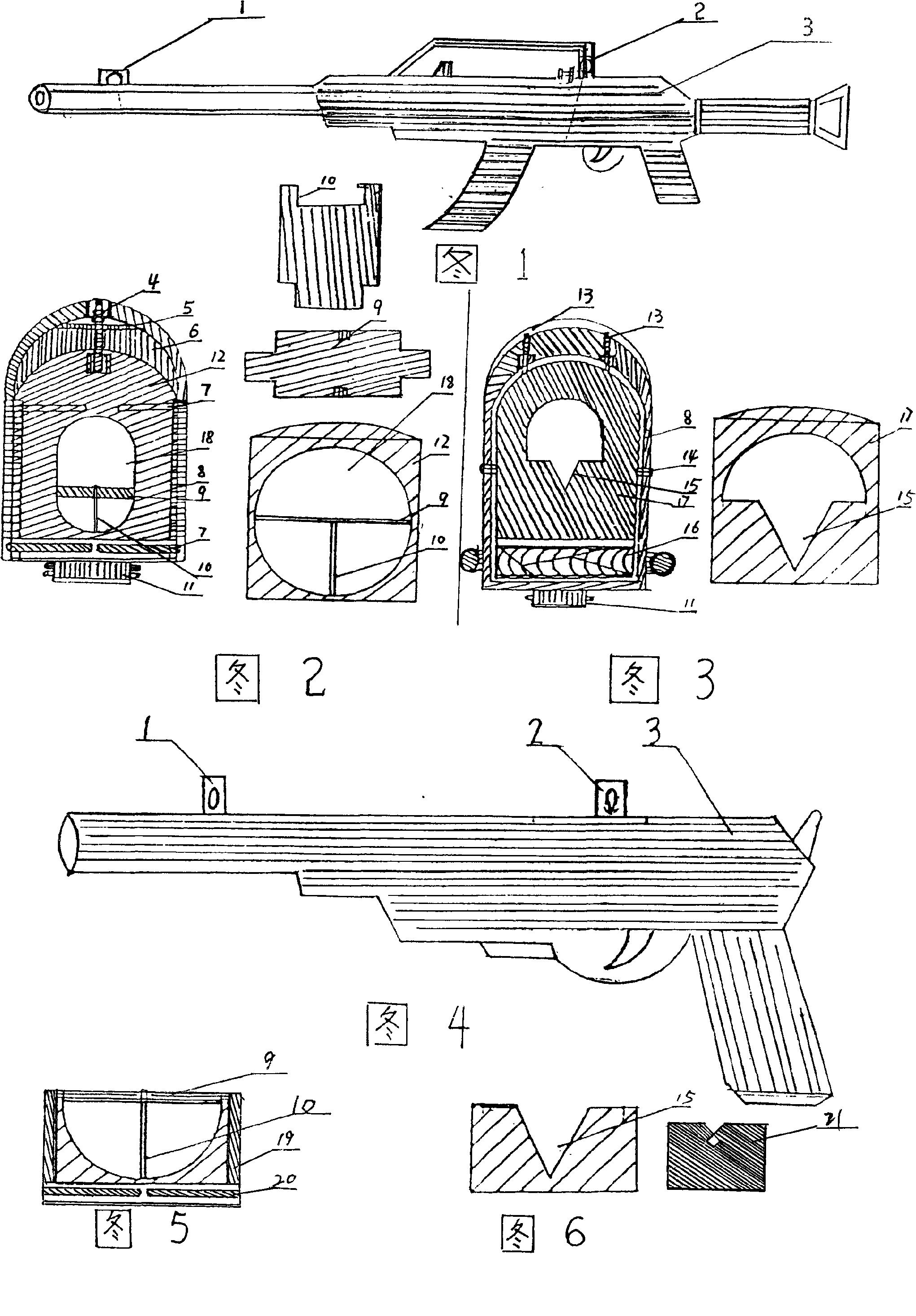

[0015] As shown in Figures 1-6, Figures 1-3 show the configuration diagram of the charging aiming device. A screw 7, the top screw 4 is inserted from the draw-in groove slide plate 5 at the top of the nail hole to connect the front sight plate 12, and adjusted in the n-type retainer 8, which is the front sight device and fixed tightly. And be connected with gun body 3 connecting shaft 11. Notch position: set the V-shaped plate 17 of the iron sheet round cover with the inner groove of the n-shaped retainer 8. Tighten the two positioning nails and telescopic spring 13 at the top, put the scale roller 16 into the lower end of the n-type retainer, adjust and fix the V-shaped plate 17 and n retainer 8 with rivets 14, turn the scale roller to move the gap height up and down, and then the gap device 15 Combining with the charging notch 2, the installation is complete. Wherein Fig. 4-Fig. 6 shows pistol sight device configuration diagram, the T-type front sight plate 9,10 in Fig. 5 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com