Eyeglasses frame elastic hinge

An elastic hinge and spectacle frame technology, which is applied to glasses/goggles, optics, instruments, etc., can solve the problems of inseparable elastic hinges and scrapped temples of spectacle frames, and achieve the effect of convenient and quick loading and unloading and saving resources.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

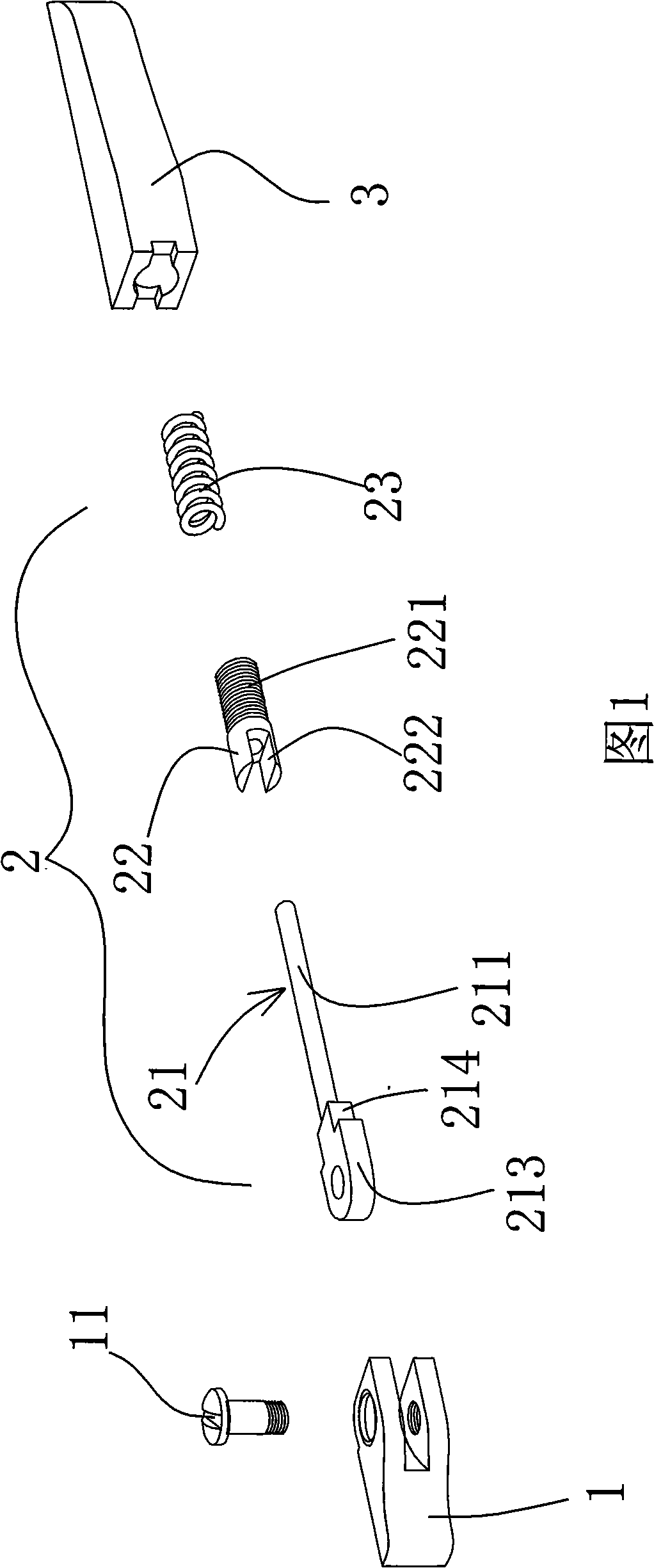

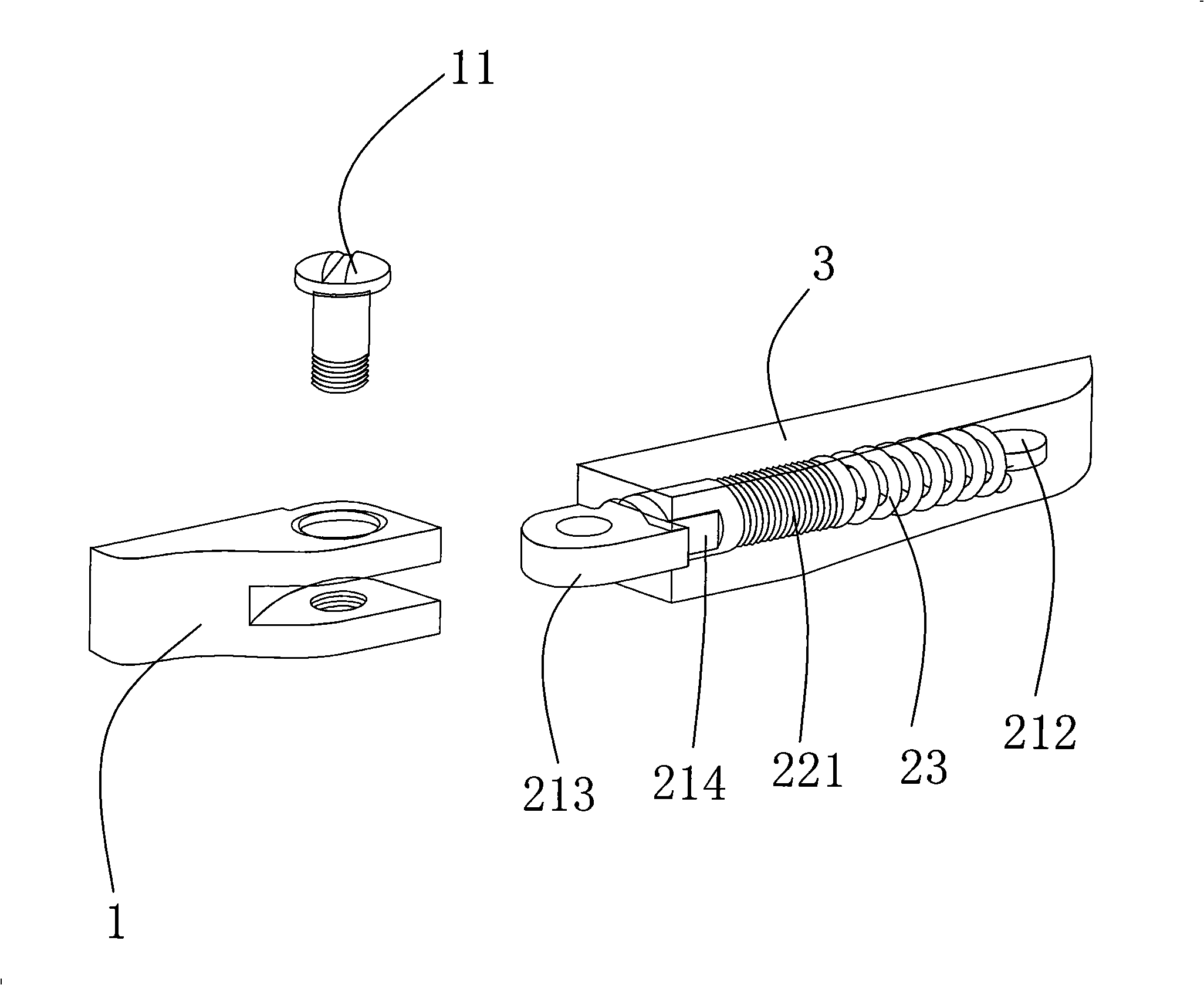

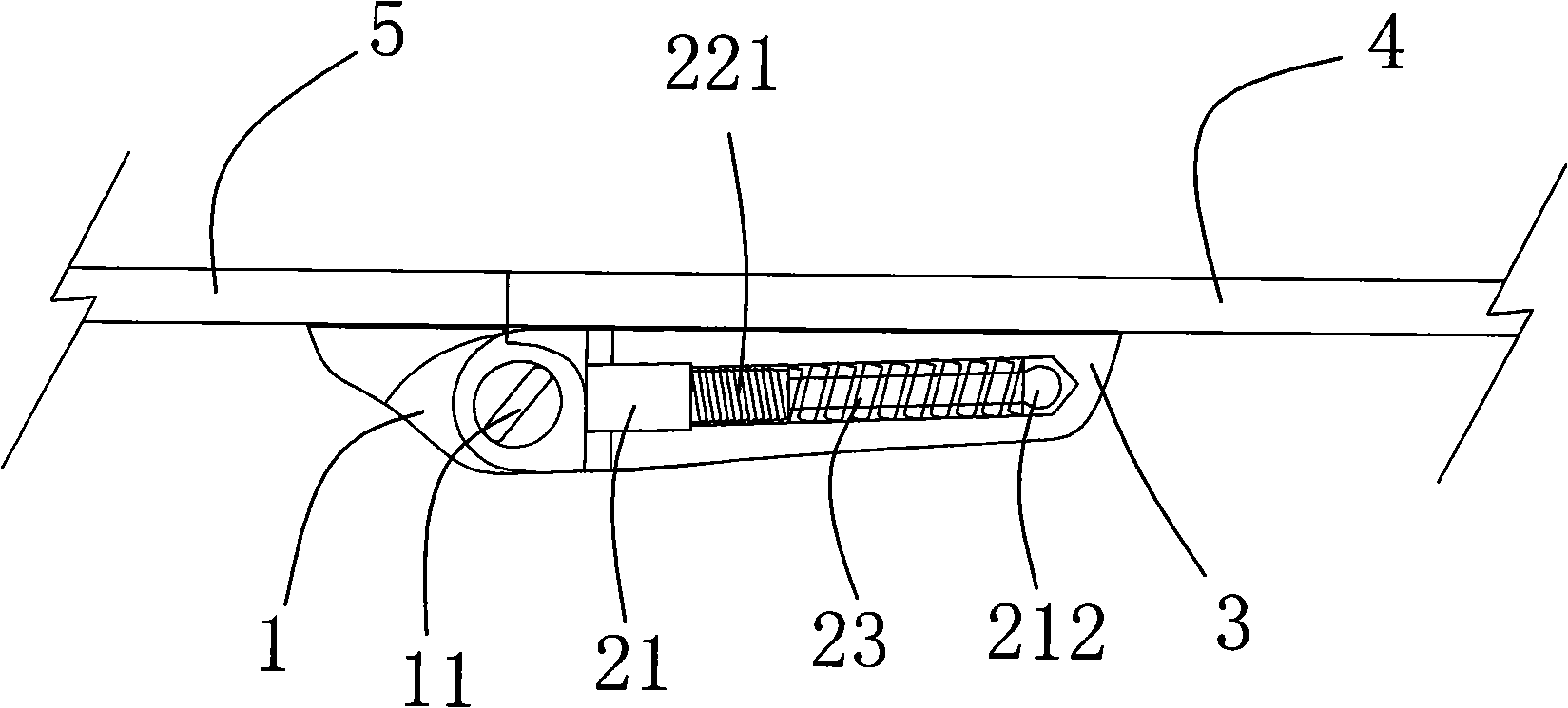

[0019] See Figure 1 and figure 2 , It is an elastic hinge for spectacle frames, including hinge double teeth 1, slingshot core 2 and slingshot box body 3, said slingshot core 2 includes single tooth core body 21, positioning member 22 and spring 23, said positioning member 22 And the spring 23 is sleeved on the single tooth handle 211 of the single tooth core 21, the spring 23 is located behind the positioning member 21, and a flat position 212 is provided at the end of the single tooth handle 211 to prevent the spring from falling off The first end 213 of the single-tooth core 21 and the hinge double-tooth 1 are movably connected by screws 11, the positioning member 22 and spring 23 of the slingshot core 2 are arranged in the slingshot box 3, the slingshot The core 2 is detachably connected to the slingshot box body 3 through its positioning member 22. Specifically, the detachable connection is provided with an external thread 221 on the outer wall of the positioning member 22, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com