Inversely winding type constant-force spring mechanism

A constant-force spring, coil-type technology, applied in the field of constant-force spring mechanisms, can solve the problems of difficulty in achieving constant-force requirements, large changes in thrust or pulling force, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

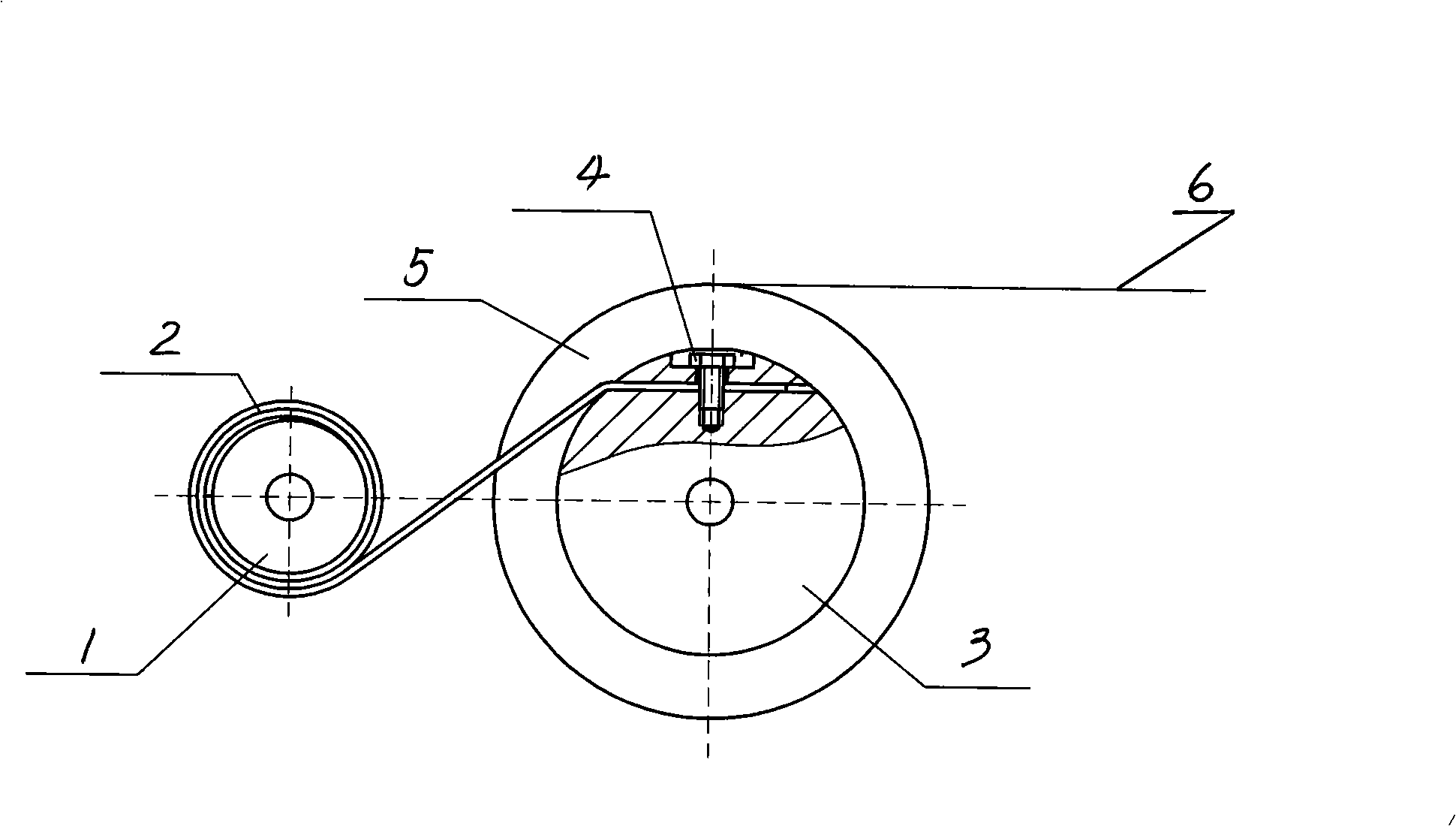

[0008] Embodiments of the present invention will be further described below with reference to the accompanying drawings.

[0009] The present invention comprises a driven wheel 1, a retracting wheel 3 and an output wheel 5, one end of the constant force spring 2 is wrapped on the driven wheel 1, and the other end of the constant force spring 2 is fixed and rolled back on the retracting wheel 3; the output wheel 5 and The retracting wheel 3 is fixedly connected and coaxial; the diameter of the retracting wheel is larger than that of the driven wheel.

[0010] The working principle of the present invention: put the formed constant force spring on a driven wheel, fix one end of the constant force spring on the retracting wheel with a fixing bolt, and set an output wheel coaxially with the retracting wheel, and the retracting wheel The wheel is fixedly connected with the output wheel, and the output wheel is wound with a rope. When the rope is pulled out, the output wheel drives t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com