Electric power driven car multi-motor driving structure

A multi-motor drive, electric vehicle technology, applied in the field of electric vehicles, can solve the problems of poor starting and acceleration performance of electric vehicles, large motor current, and insufficient power.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

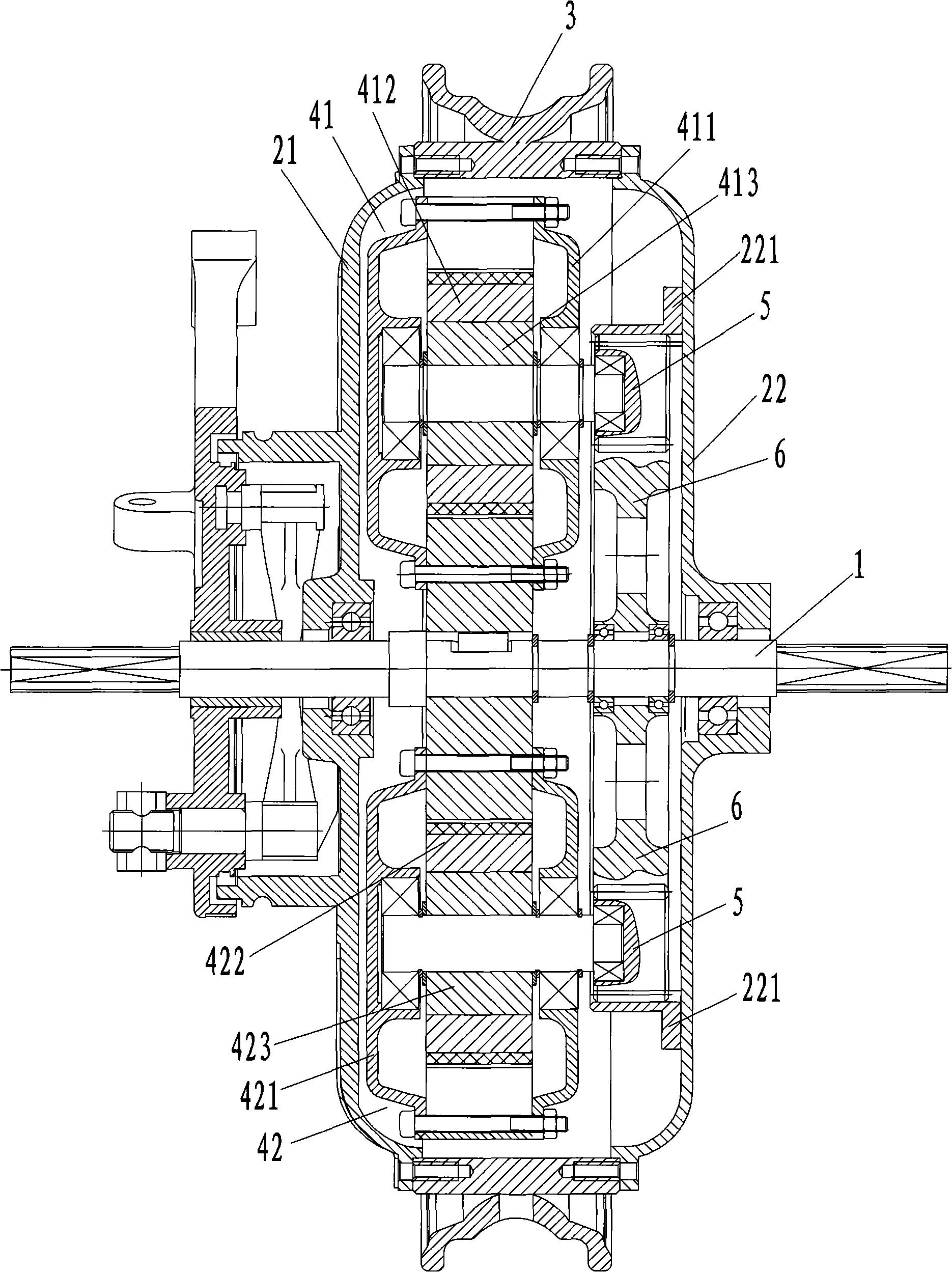

[0009] Such as figure 1 As shown, a multi-motor drive structure of an electric vehicle includes a main motor 41, an auxiliary motor 42, a hub shell 3, a left end cover 21, a right end cover 22 and a motor shaft 1, and the hub end covers 21, 22 are fixedly connected to the hub shell 3, there is a motor shaft hole at the center of the hub end cover 21, 22, and the motor shaft 1 runs through the center shaft hole of the end cover 21, 22, and the motor 41, 42 includes a housing 411, 421, a stator 412, 422 and rotors 413, 423, two motors 41, 42 are arranged above and below the motor shaft 3 respectively, the stators 412, 422 of the two motors 41, 42 are fixed on the motor shaft 3 by bayonet pins, and the motors The casings 411, 421 are fixedly connected to the motor stators 412, 422 by bolts, the two ends of the rotors 413, 423 of the motors 41, 42 are positioned on the motor casings 411, 421 through bearings, and the rotors 413, 423 are accommodated in the stator 412 , 422, there...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com