Lead detection device

A detection device and wire technology, applied in the direction of material breakdown voltage, material impedance, etc., can solve problems such as the influence of wire appearance quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

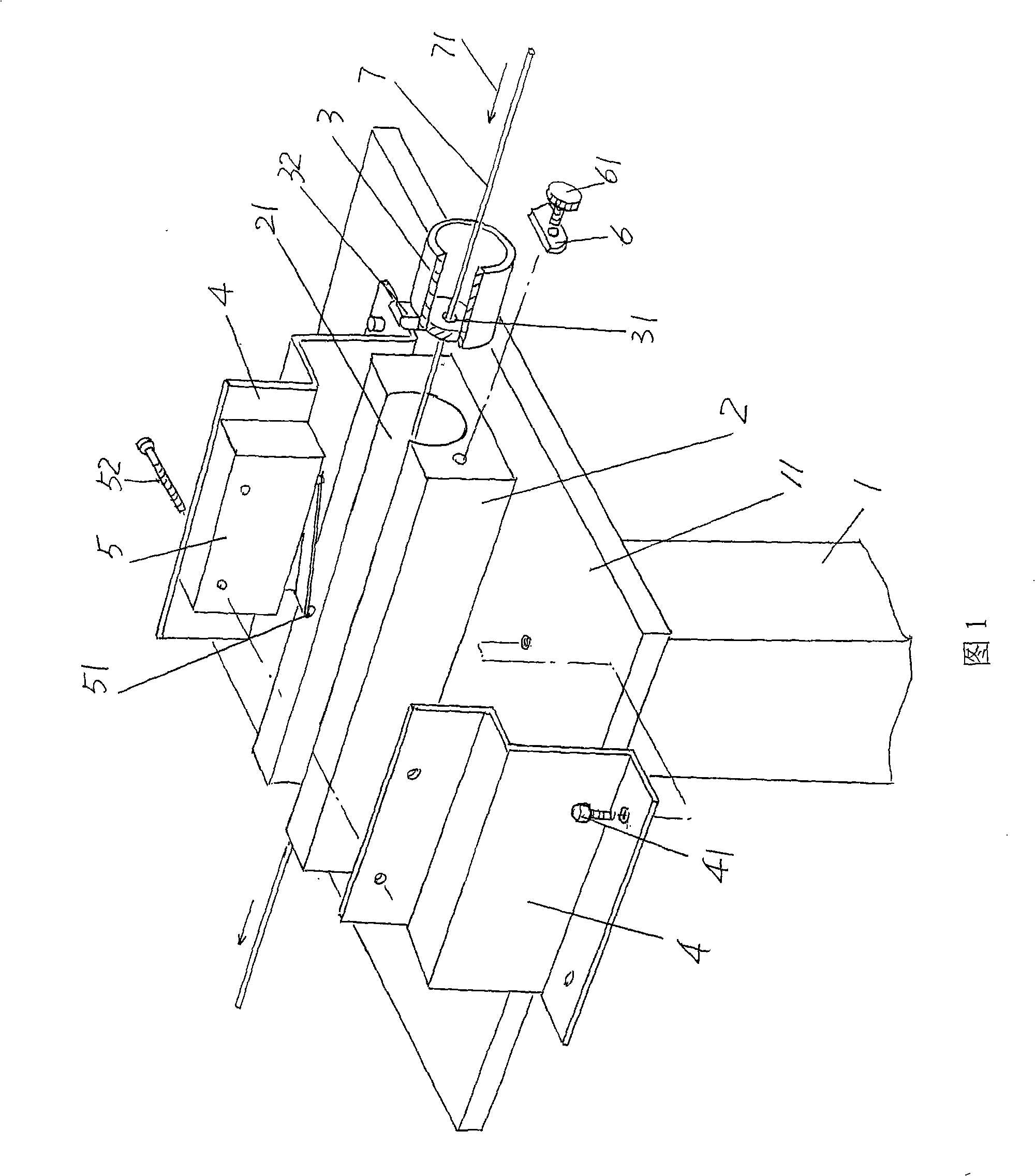

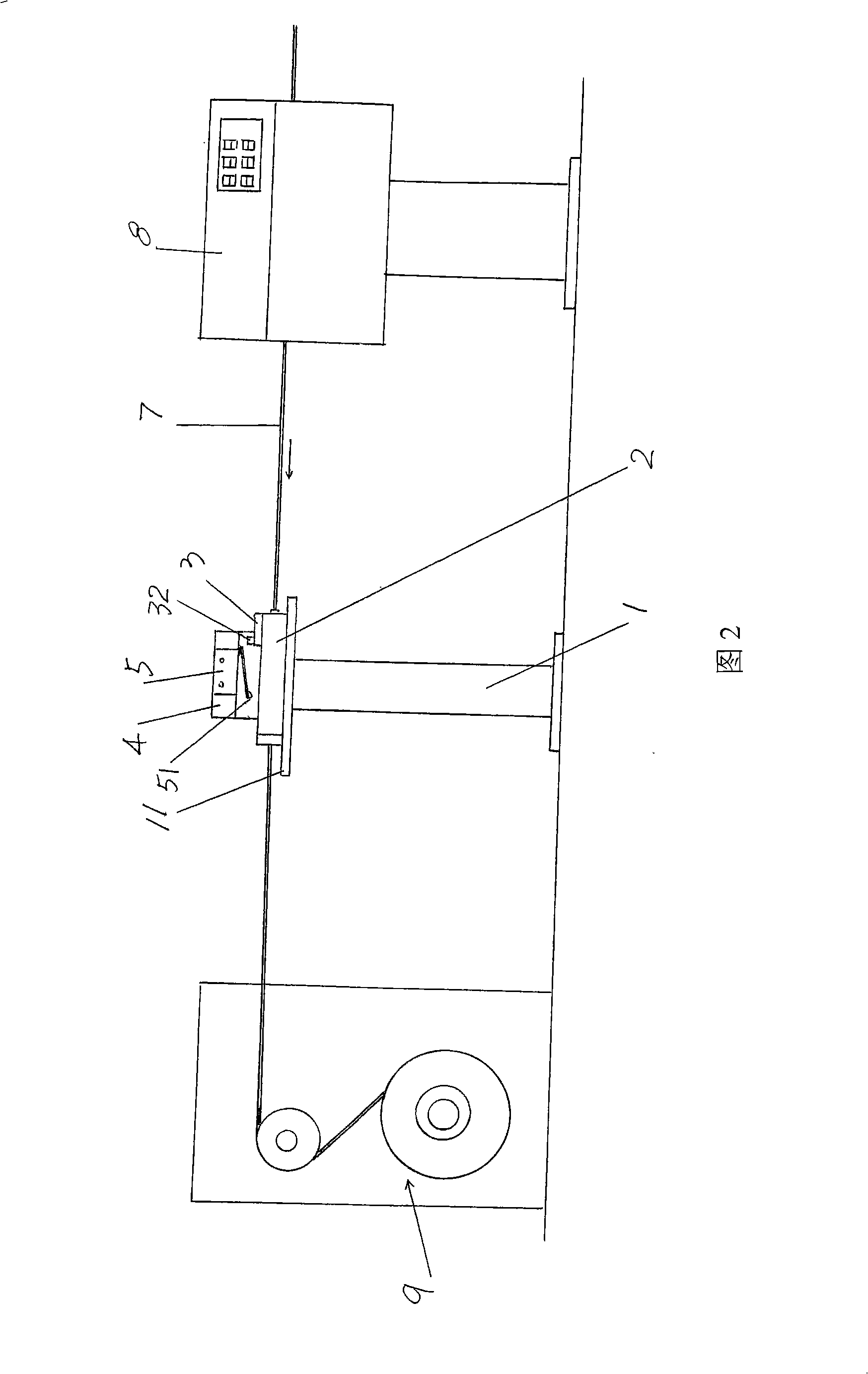

[0017] Please see Fig. 1, in this embodiment of the present invention, needn't limit for the shape of frame 1 and specific structure, for example it can be made of at least one or more than one leg, table top 11 is fixed with horizontal state On rack 1. In order to facilitate the public's understanding, in this figure, the applicant schematically shows the wire 7 , and marks the arrow 71 at the wire 7 indicating the direction of travel of the wire 7 . Because the wire detection device of the present invention is equipped between the outer sheath damage detector 8 shown in Figure 2 and the wire winding device 9 under the use state, therefore taking the current position state shown in Figure 1 as an example, Wire 7 moves from right to left. A detection sleeve 2 is fixed on the table top 11 in the same direction as the wire 7. The central recess in the length direction of the detection sleeve 2 is provided with a U-shaped chute 21, and the two ends of the chute 21 are The notch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com