Fuel injector having a directly actuable injection valve element

A technology of fuel injectors and injection valves, which is applied to fuel injection devices, fuel injection valves driven by fluid pressure, engine components, etc., and can solve problems such as injection quantity fluctuations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

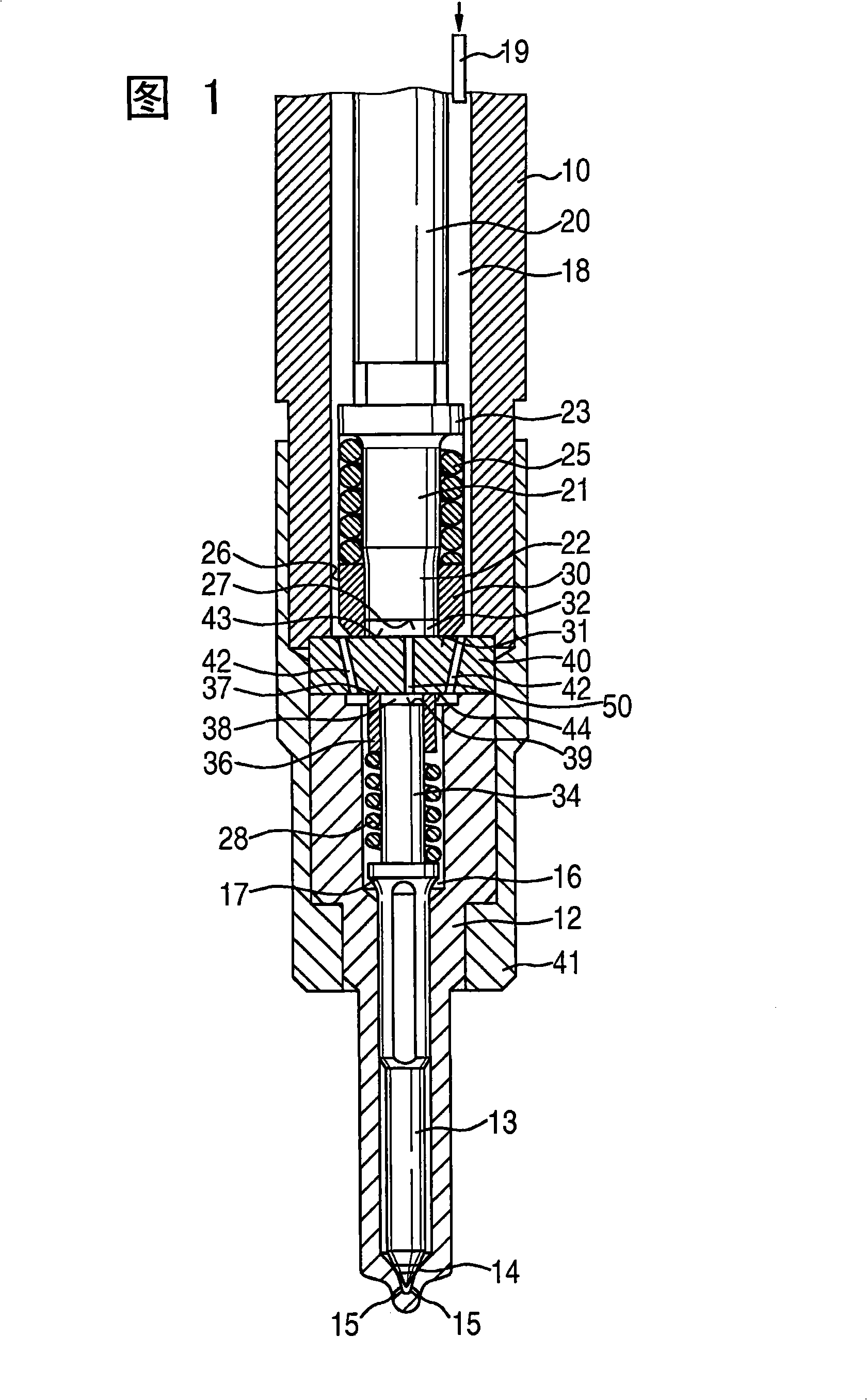

[0012] The fuel injector shown in FIG. 1 has an injector housing 10 with an injection valve element which projects with a nozzle body 12 into a combustion chamber of the internal combustion engine. A nozzle needle 13 is guided axially displaceably in the nozzle body 12 . At the tip of the nozzle needle 13, a nozzle needle seal seat 14 is formed on the nozzle body 12, behind which the nozzle 15, which is formed in the nozzle body 12 and protrudes into the combustion chamber, is arranged in the injection direction. . A nozzle needle pressure chamber 16 , in which a nozzle needle-side pressure shoulder 17 formed on the nozzle needle 13 is situated, is arranged upstream of the nozzle needle sealing seat 14 in the injection valve element in the spraying direction.

[0013] The injector housing 10 has a pressure chamber 18 which is connected via a connection 19 to a high-pressure system (not shown), for example a common rail system of a diesel injection system. A piezoelectric act...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com