Damping device and damping methdo

A vibration damping device and vibration absorber technology, which is applied in the direction of spring/shock absorber, vibration suppression adjustment, mechanical equipment, etc., can solve the problems of no effect and unable to reduce forced vibration, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment approach

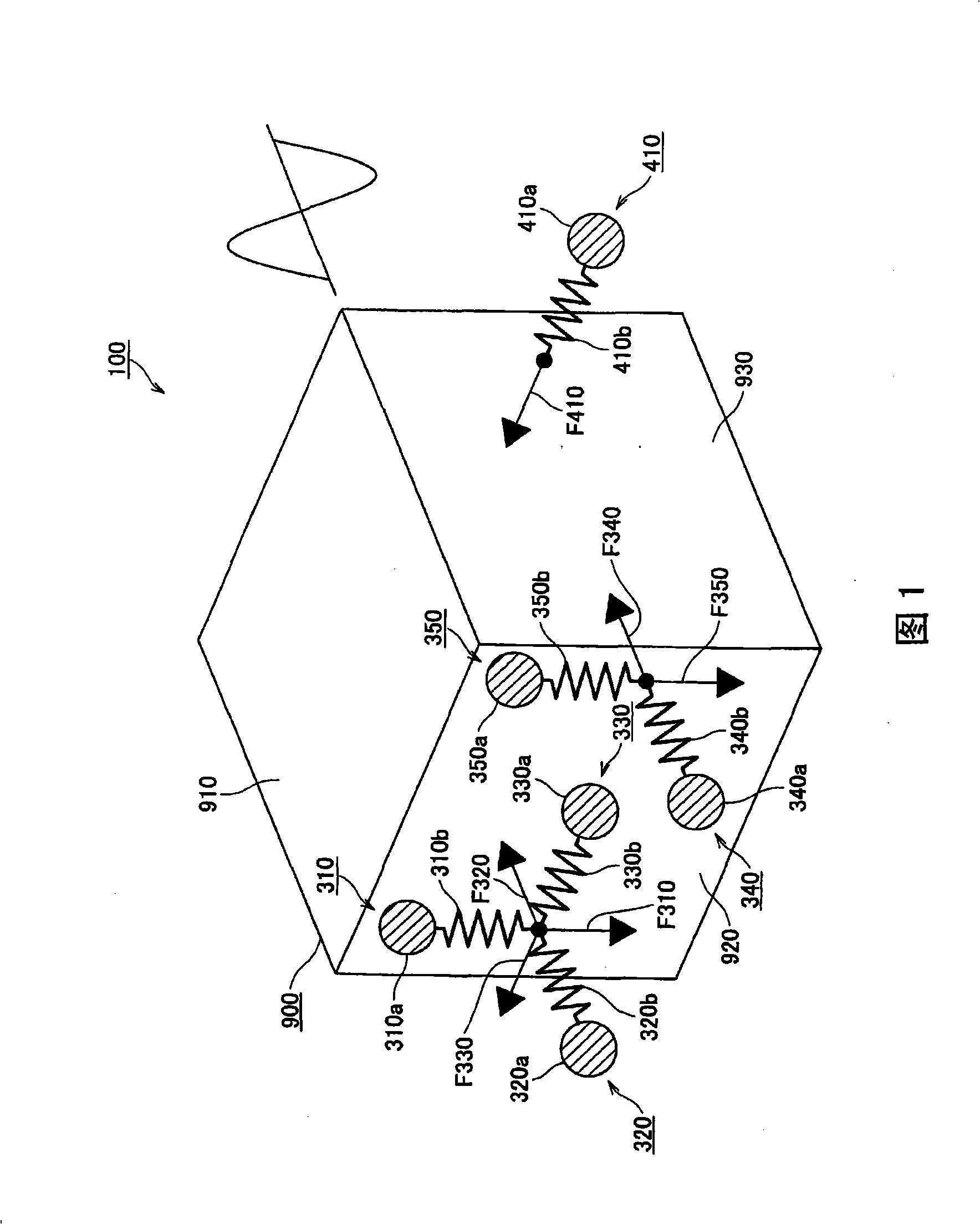

[0061] FIG. 1 is a schematic diagram showing an example of a vibration suppressing device 100 according to a first embodiment of the present invention.

[0062] As shown in FIG. 1 , the vibration suppression device 100 includes six dynamic vibration absorbers 310 , 320 , 330 , 340 , 350 and 410 , and the vibration suppression device 100 is installed on a box-shaped member 900 such as an engine or a motor.

[0063] As shown in FIG. 1 , on the surface 920 of the box-shaped member 900 of the vibration suppressing device 100, the dynamic vibration absorbers 310, 320, 330, 340, and 350 are provided, and on the surface 930 of the box-shaped member 900, the dynamic vibration absorber 410 is provided. .

[0064] As shown in FIG. 1, the dynamic vibration absorber 310 is comprised by the weight part 310a and the spring 310b. In addition, the dynamic vibration absorber 320 is composed of a hammer portion 320a and a spring 320b; the dynamic vibration absorber 330 is composed of a hammer ...

no. 2 Embodiment approach

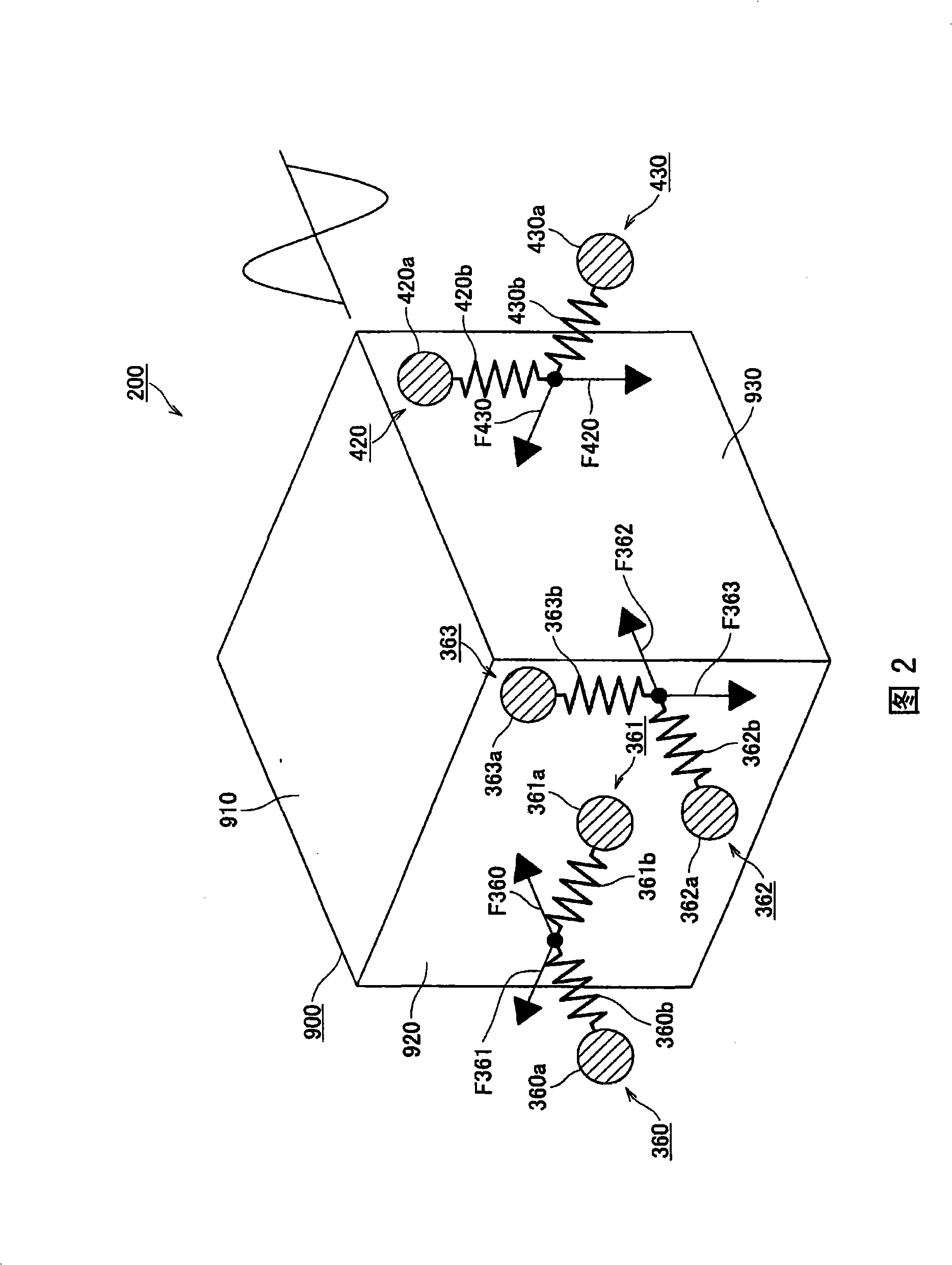

[0073] FIG. 2 is a schematic diagram showing an example of a vibration suppressing device 200 according to a second embodiment of the present invention.

[0074] As shown in FIG. 2 , the vibration suppression device 200 includes six dynamic vibration absorbers 360 , 361 , 362 , 363 , 420 and 430 , and the vibration suppression device 200 is installed on a box-shaped member 900 such as an engine or a motor.

[0075] As shown in FIG. 2, on the surface 920 of the box-shaped member 900 of the vibration suppressing device 200, dynamic vibration absorbers 360, 361, 362, 363 are provided, and on the surface 930 of the box-shaped member 900, a dynamic vibration absorber 420 is provided. , 430.

[0076] As shown in FIG. 2, the dynamic vibration absorber 360 is comprised by the weight part 360a and the spring 360b. In addition, the dynamic vibration absorber 361 is composed of a hammer portion 361a and a spring 361b; the dynamic vibration absorber 362 is composed of a hammer portion 36...

no. 3 Embodiment approach

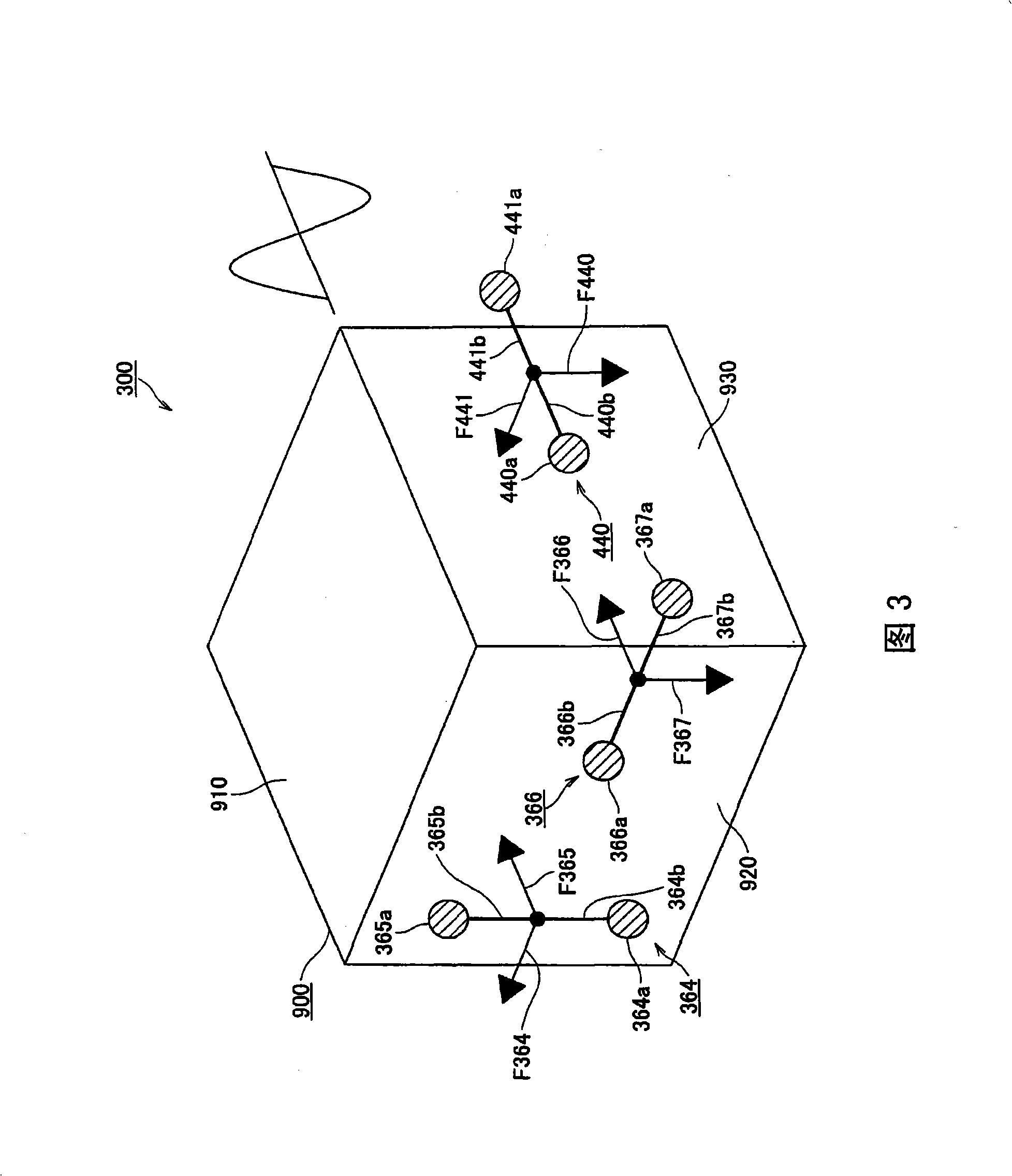

[0084] FIG. 3 is a schematic diagram showing an example of a vibration suppression device 300 according to a third embodiment of the present invention.

[0085] As shown in FIG. 3 , the vibration suppressing device 300 includes dynamic vibration absorbers 364 , 366 , and 440 , and the vibration suppressing device 300 is installed on a box-shaped member 900 such as an engine or an electric motor.

[0086] As shown in FIG. 3 , dynamic vibration absorbers 364 and 366 are provided on the surface 920 of the box-shaped member 900 of the vibration suppressing device 300 , and a dynamic vibration absorber 440 is provided on the surface 930 of the box-shaped member 900 .

[0087] Here, FIG. 4 is a schematic diagram showing the dynamic vibration reducers 364, 366, and 440 in FIG. 3 .

[0088] As shown in FIG. 4, the dynamic vibration absorber 364 is comprised by the hammer part 364a, 365a and the round bar 364b, 365b which has elastic force. Also, the dynamic vibration absorber 366 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com