Saw-blade type field straw returning machine

A technology of straw and saw blades, which is applied in the field of saw blade straw returning machines, can solve the problems of affecting land cultivation, easy wear of blades, high fuel consumption of tractors, etc., and achieves obvious energy saving effect and short processing length

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

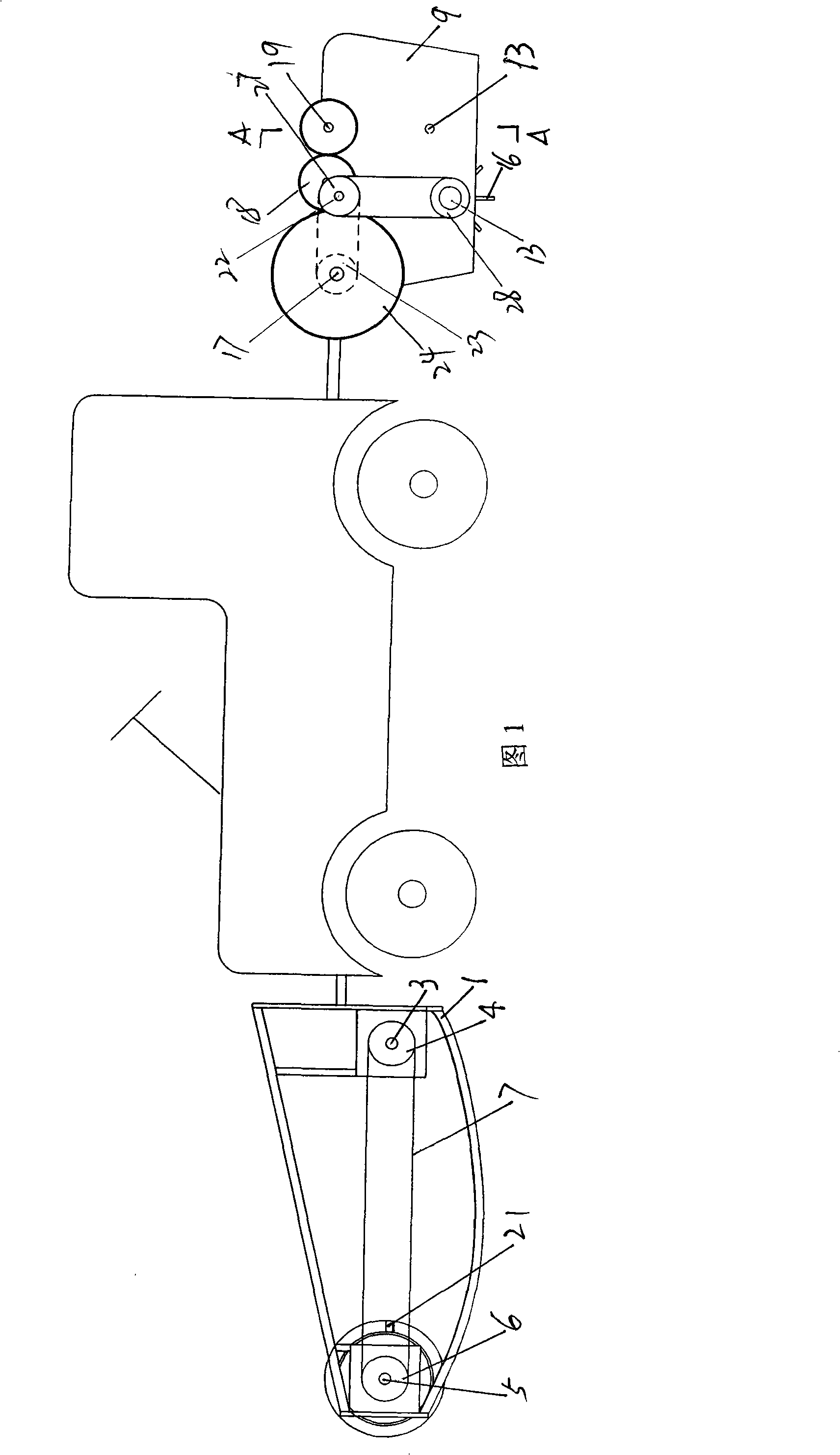

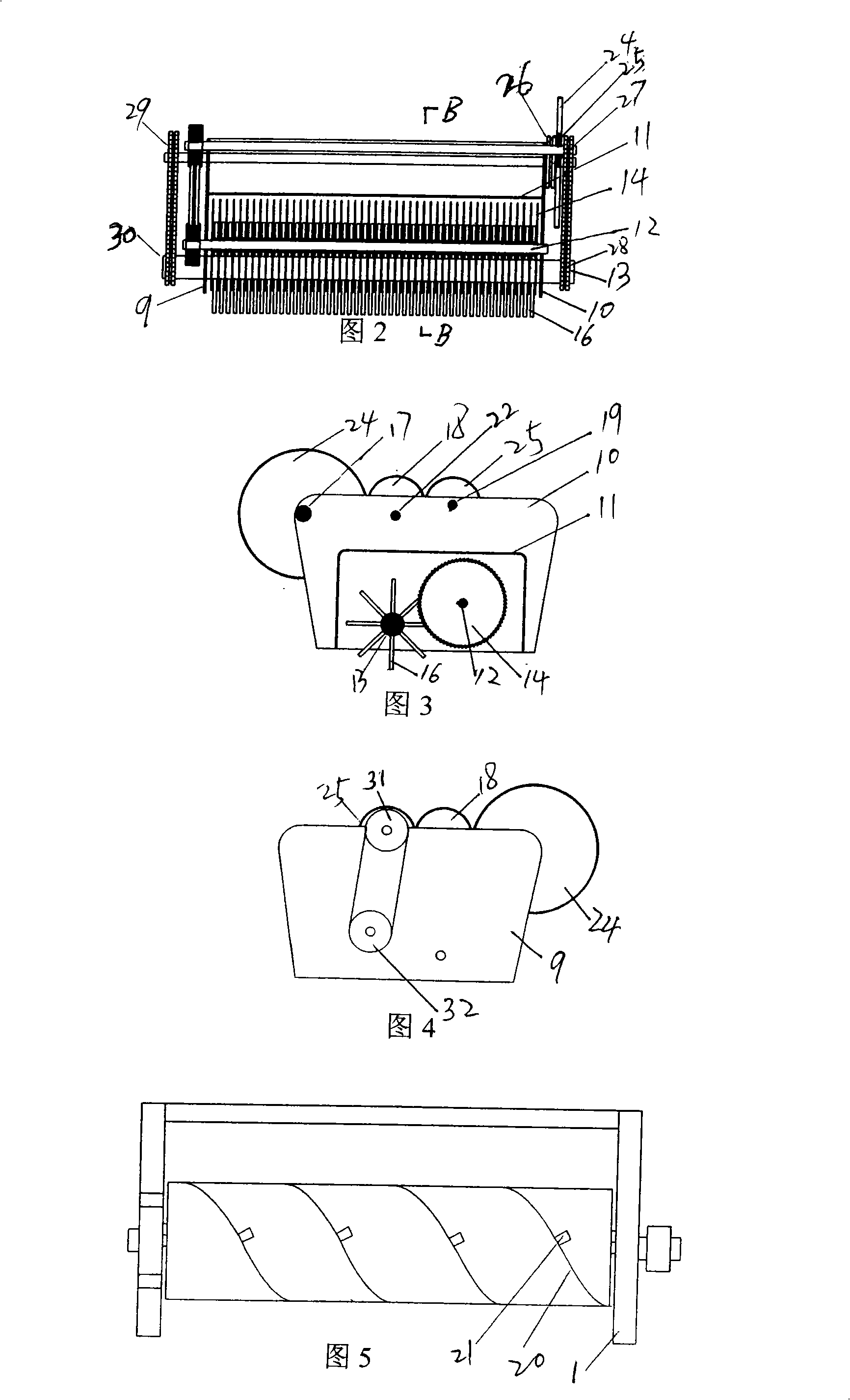

[0020] A saw blade type straw returning machine, which is composed of a tractor, a straw dumping device, a straw crushing device and a power transmission device. The straw dumping device is a spiral drum type straw horizontal dumping device. On the spiral piece 20 on the spiral drum 2, a plurality of small steel plates 21 perpendicular to the spiral piece 20 are installed and fixed, the transmission shaft 3 is installed at the rear of the drum frame 1, and the straw dumping device is installed at the front of the tractor, and the straw is crushed. The device is a saw blade type straw crushing device, and the saw blade shaft 12 with multiple saw blades (14) and the thorn shaft 13 with multiple rows and multiple thorns 16 are installed on the bottom of the fuselage. The front part of the thorn shaft 13, the multi-row thorns 16 are axially located between the multi-blade saw blades 14, the straw crushing device is installed at the rear of the tractor, and the fuselage is composed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com