Solid engines CT image division method

A solid engine, CT image technology, applied in image analysis, image enhancement, image data processing, etc., can solve the problems of poor segmentation effect and non-universal applicability, and achieve the effect of low efficiency and poor accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] A solid engine CT image segmentation method provided by the present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

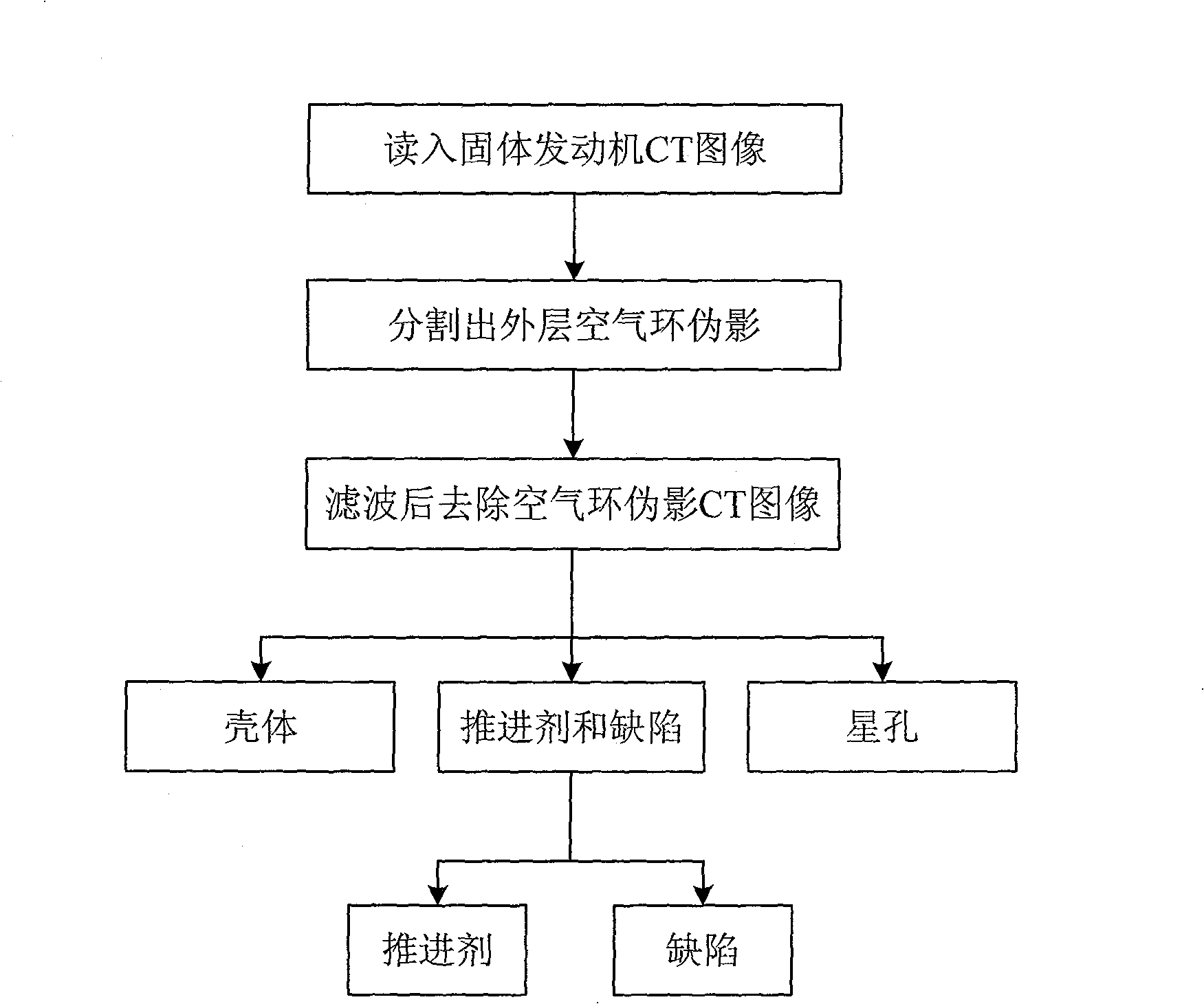

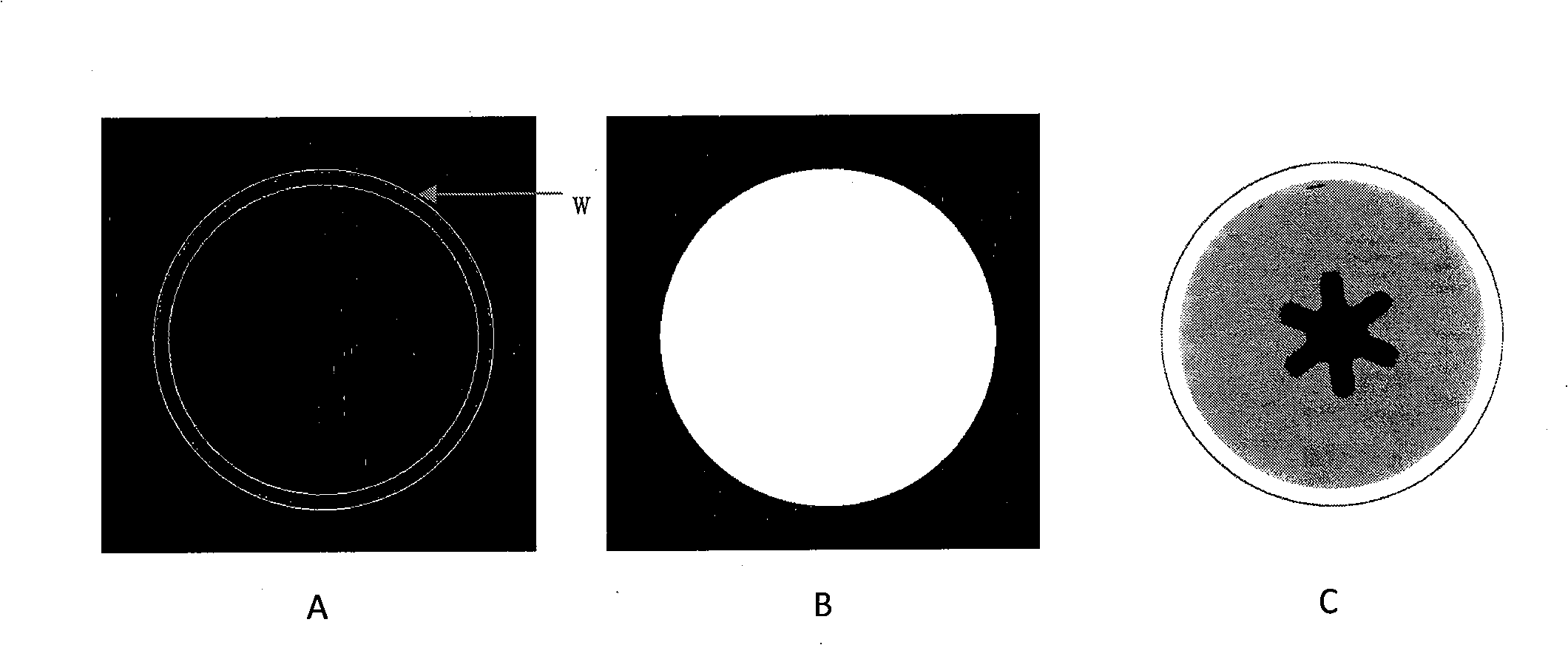

[0036] figure 1 It shows the overall flow of the solid motor CT image segmentation method according to the embodiment of the present invention. Firstly, the data of the solid motor CT tomographic image (hereinafter referred to as CT image) is read in; The air ring artifacts formed by air disturbance outside the solid motor casing; the image after de-artifacting is filtered by median filtering to filter out the background noise, and at the same time sharpen the edges of the components of the solid motor in the CT image; based on the multi-threshold method, Segment solid engine case, propellant, and star holes in CT images; finally segment defects from propellant.

[0037] In the above embodiment, firstly, the CT tomographic image data of the solid motor is read in.

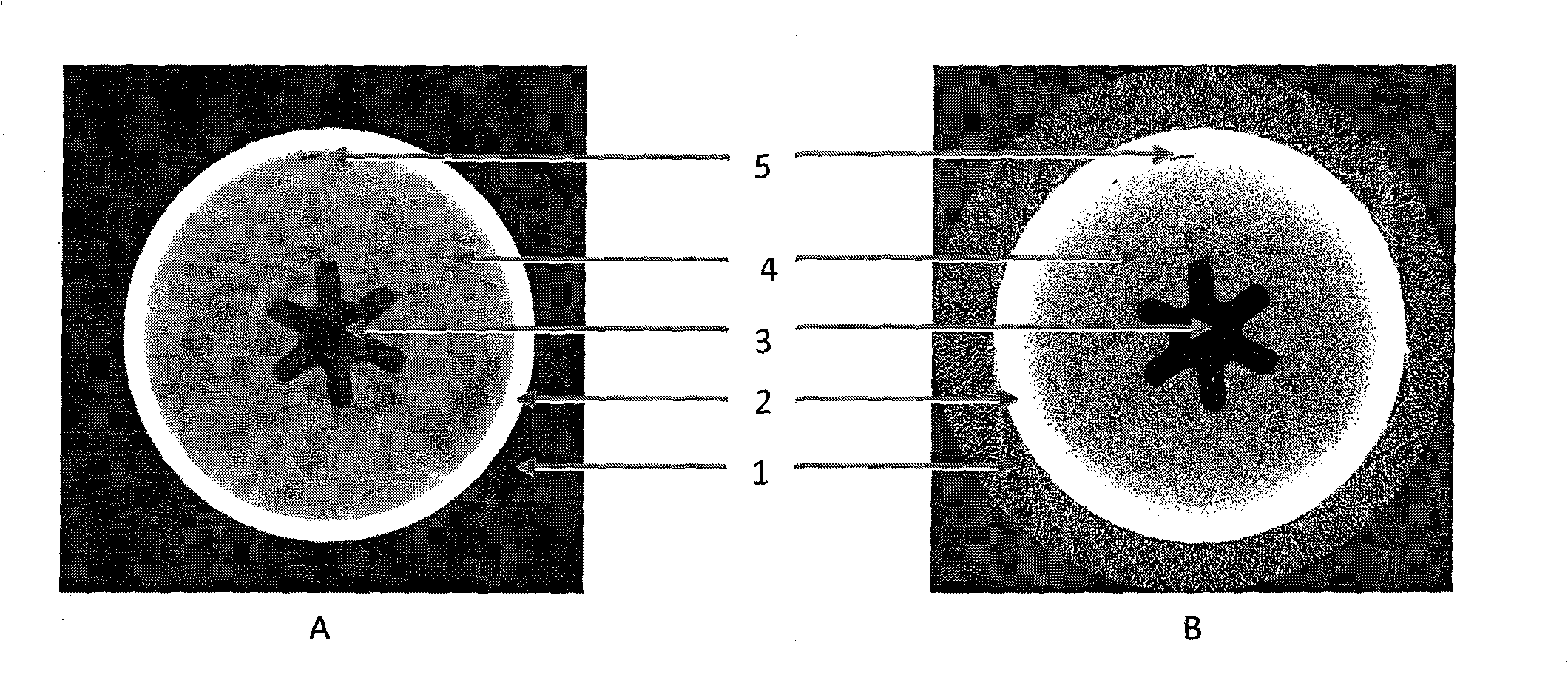

[0038] figure 2 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com