Filling pipe with anti-overflow system

A crane tube and anti-overflow technology, which is applied in the field of crane tubes, can solve the problems of no overflow anti-overflow system and potential safety hazards, and achieve the effect of eliminating potential safety hazards and ensuring safe transportation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

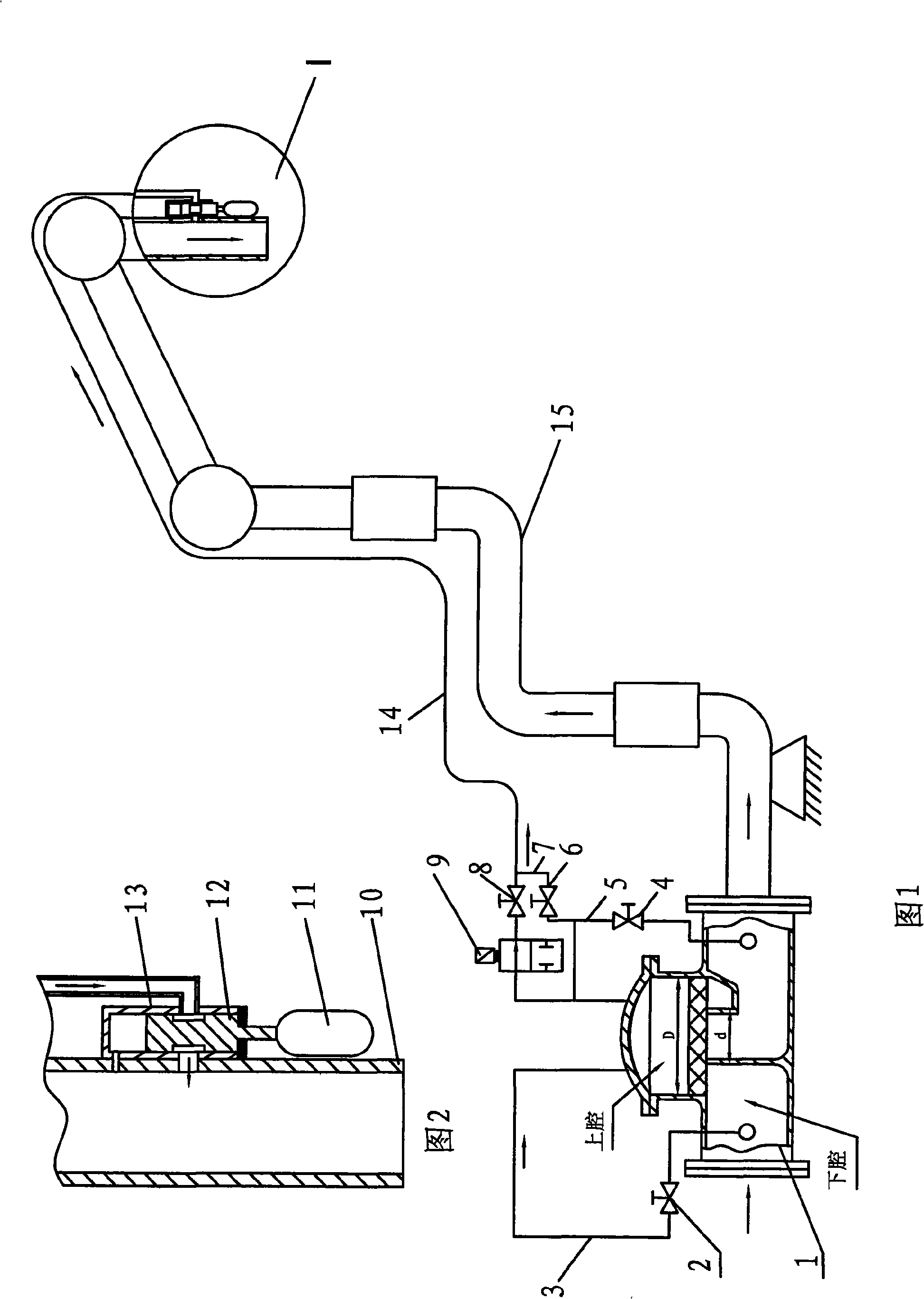

[0015] As shown in Figure 1-2, a crane pipe with an overflow prevention system consists of a pressure on-off valve 1 and a crane pipe 15, which connect the lower chamber of the pressure on-off valve 1 with the upper chamber of the pressure on-off valve 1 The upper chamber oil inlet pipe 3, the upper chamber oil outlet pipe 5 connecting the upper chamber of the pressure on-off valve 1 with the oil outlet of the pressure on-off valve 1, and the manual adjustment valve 4 installed on the upper chamber oil outlet pipe 5, its characteristics Yes: an upper chamber oil outlet shunt pipe 14 parallel to the crane pipe 15 is connected in parallel to the upper chamber oil outlet pipe 5, and a control upper chamber oil outlet shunt pipe 14 is vertically installed and fixed on the oil outlet section 10 of the crane pipe 15 buoyancy on-off valve. The buoyancy on-off valve is a plunger sliding on-off valve composed of a float 11, a plunger 12 and a tubular valve body 13. There is an annular ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com