Violin structure

A violin and violin bridge technology, applied in the field of new violin structure, can solve the problems of high production process requirements and strict production material requirements, and achieve significant social benefits, cost reduction, material selection and production process simplification.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The specific embodiments of the present invention will be described below with reference to the accompanying drawings:

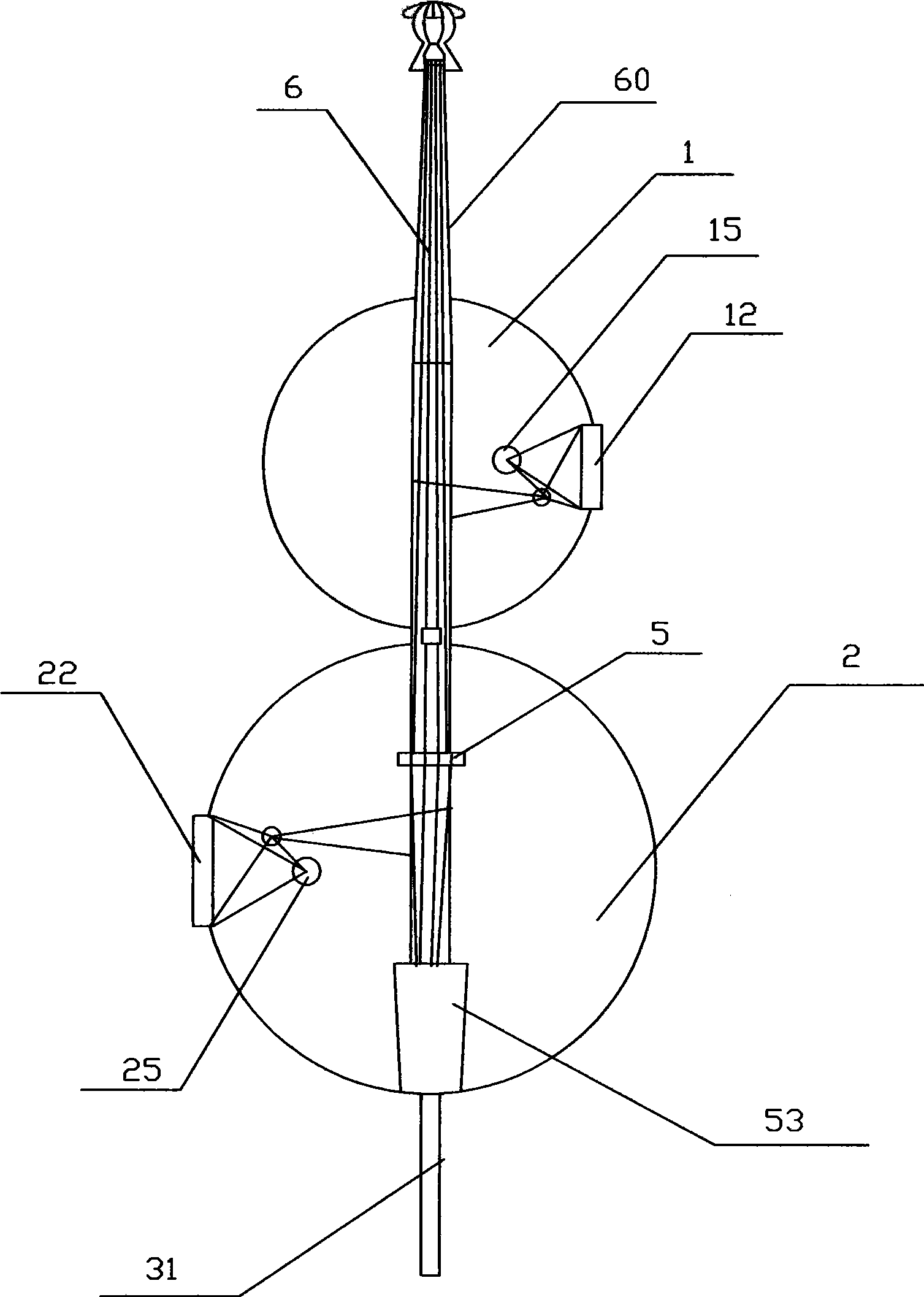

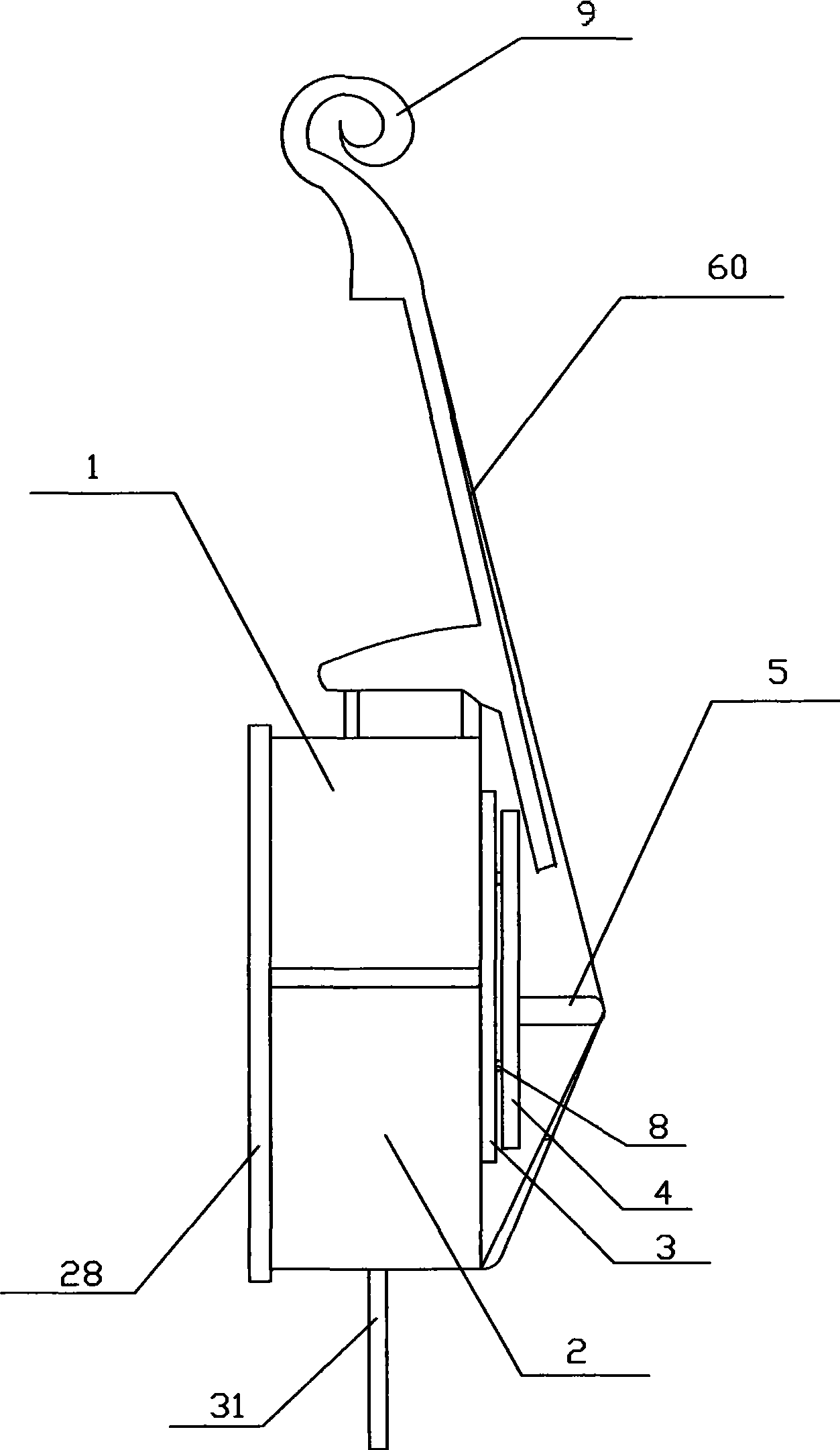

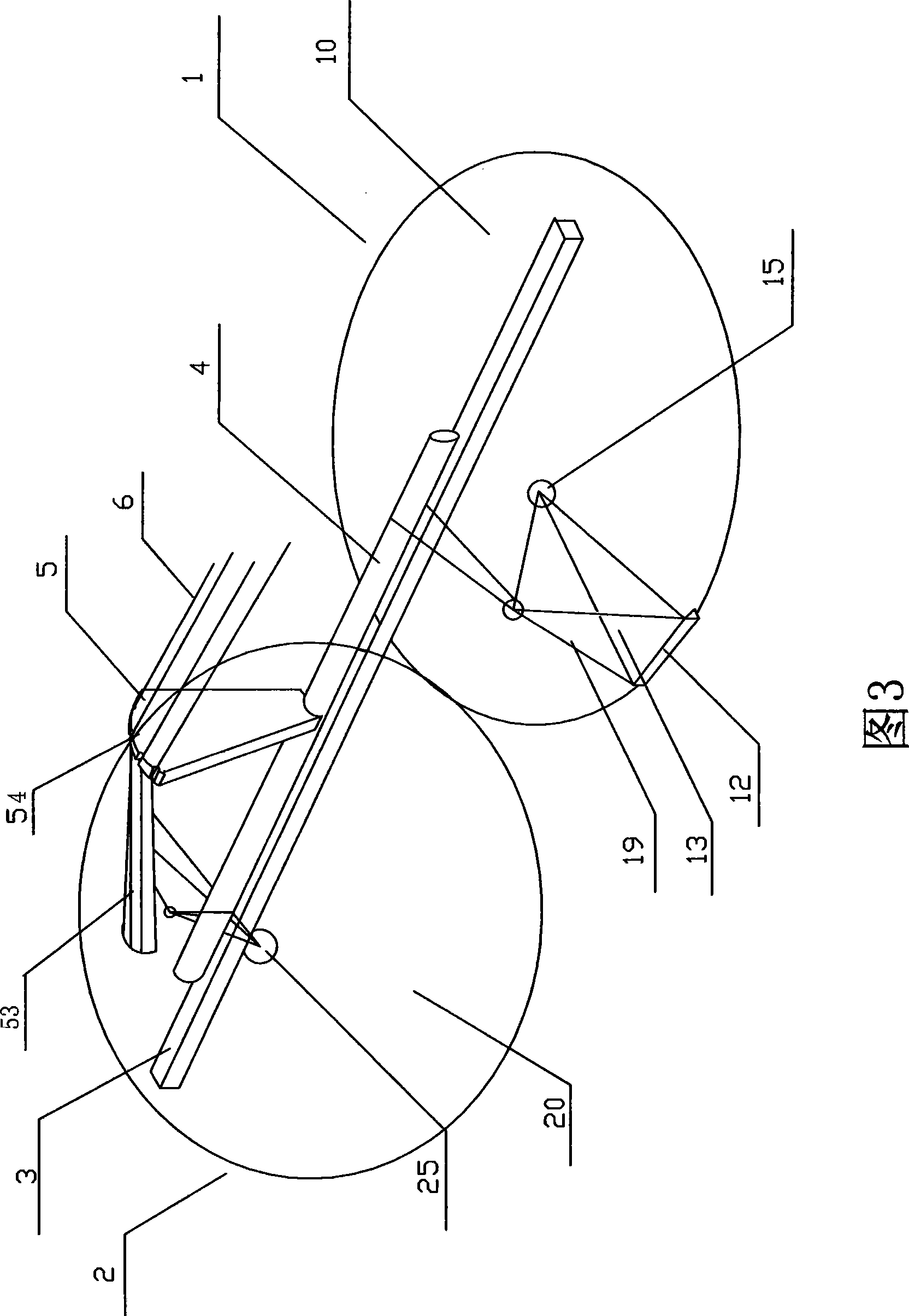

[0019] See figure 1 , figure 2 , Figure 3, Figure 4. From figure 1 It can be seen that 9 is the piano head, 6 is the string bow, 60 is the piano frame, 3 is the fixed frame, 53 is the pull plate, 1 is the upper piano tube, 10 is the sound film of the upper piano tube 1, and 2 is the lower piano Tube, 20 is the sound film of the lower piano tube 2, 5 is the piano code frame, 22 and 12 are the fixed fulcrums of the large and small piano tubes respectively, 25 and 15 are the gaskets of the piano tube, 19 is the lower sound guide bracket, 17 is The upper sound guide bracket, 13 is the lower sound transmission truss, 16 is the upper sound truss; 8 is the fulcrum, 18 is the adjustment device, 31 is the violin foot, 28 is the fixed connection frame on the back of the piano tube, mainly for connecting the upper and lower piano tubes Fixed connection.

[0020] 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com