Work transport device

A technology for conveying devices and workpieces, applied in operating devices, forging/pressing/hammer devices, manufacturing tools, etc., can solve problems such as large lateral space requirements, and achieve the effect of simple, easy sealing, and small lateral space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

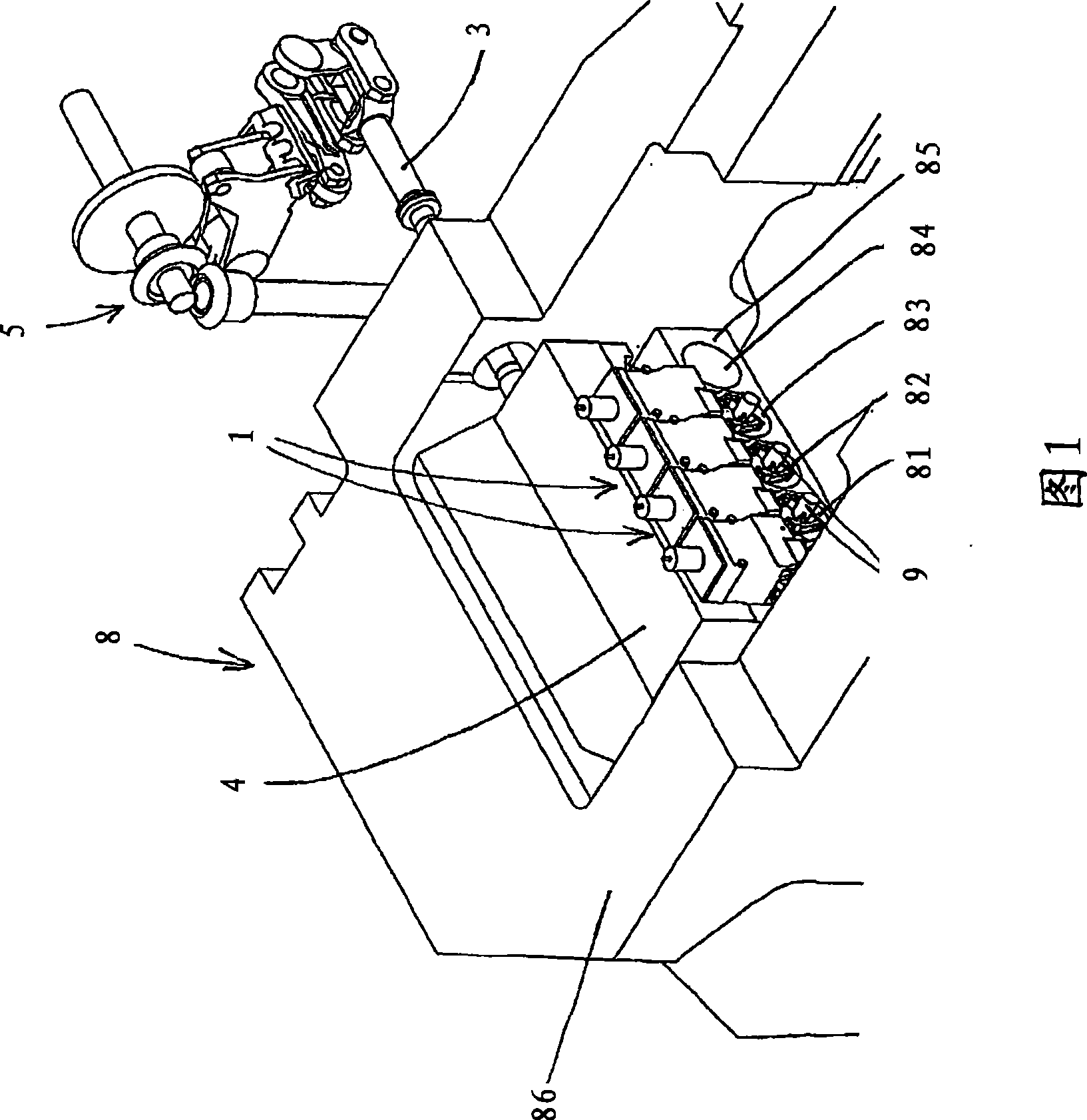

[0030] The embodiment of the multi-stage molding machine 8 shown in FIG. 1 includes four molding stations from which one mold 81, 82, 83, and 84 can be seen. These molds 81, 82, 83, and 84 are supported in a fixed mold frame 85 which is indirectly connected to a frame 86. In order to transport the workpiece 9 to each forming station and then transport it away from there, a workpiece transport device with four clamps 1 is provided. The clamps 1 can move laterally on the one hand, for which purpose they are mounted on a lateral conveying assembly 4 which can be laterally moved by means of a lateral conveying pipe. On the other hand, the clamp 1 can be opened and closed and can be raised or lowered at the same time, which is achieved by a mechanism which will be described in detail below. In order to open or close the clamp 1, a driving rod 3 that is movable in the longitudinal direction is provided, and the driving rod is longitudinally movable by means of an adjustment mechanism 5,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com