Work transport device

一种输送装置、工件的技术,应用在操作装置、锻/压/锤装置、制造工具等方向,能够解决侧向空间需求大等问题,达到实现简单、空间小、侧向空间小的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

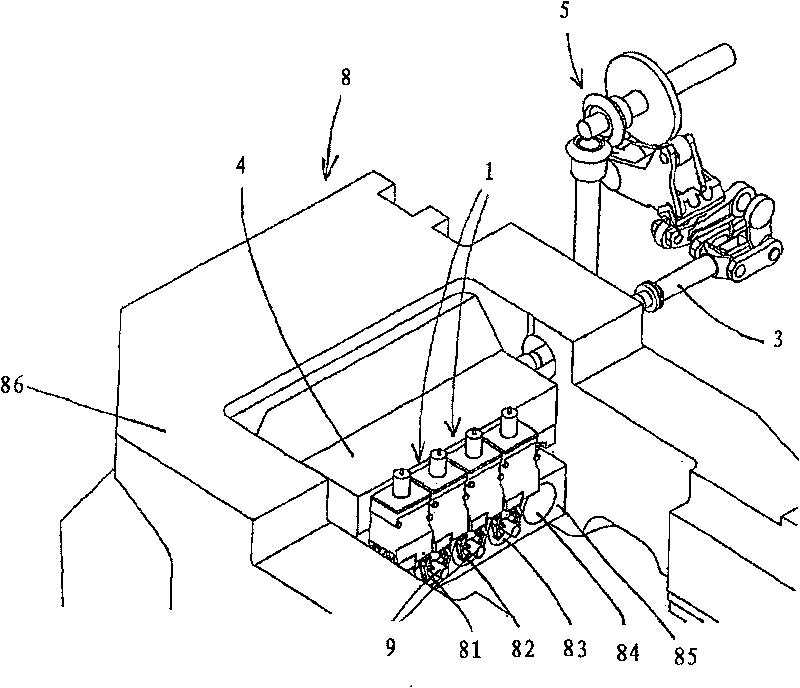

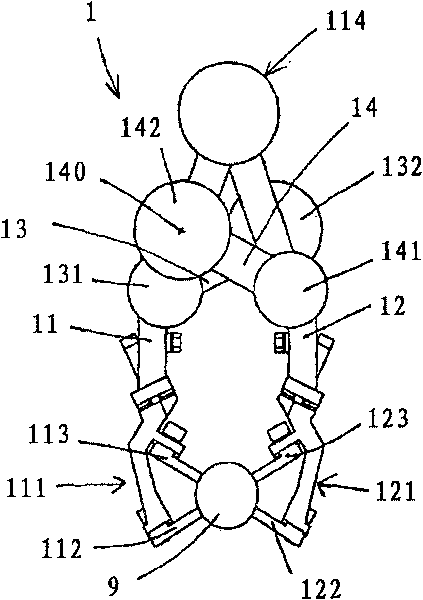

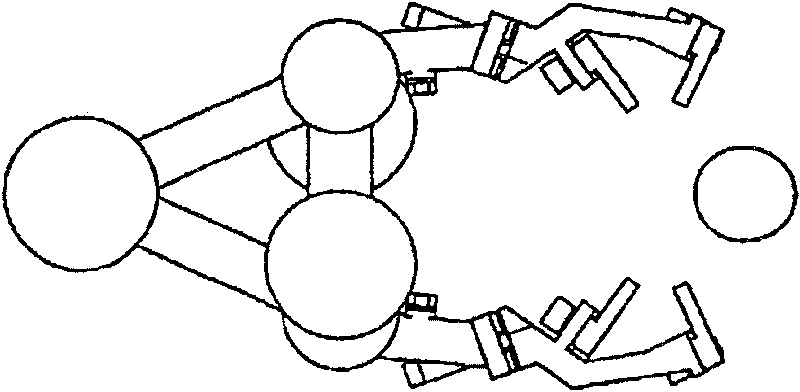

[0030] figure 1 The illustrated embodiment of the multi-stage molding machine 8 comprises four molding stations, from which a mold 81 , 82 , 83 and 84 can be seen in each case. The molds 81 , 82 , 83 , 84 are supported in a stationary mold carrier 85 which is indirectly connected to a machine frame 86 . A workpiece transport device with four grippers 1 is provided for transporting the workpieces 9 to the individual forming stations and then for transporting them away from there. The tongs 1 are on the one hand laterally displaceable, for which they are mounted on a transverse conveying unit 4 which is displaceable by means of a transverse conveying tube. On the other hand, the tongs 1 can be opened and closed and at the same time raised or lowered by means of a mechanism which will be described in more detail below. To open or close the tongs 1, a drive rod 3 displaceable in its longitudinal direction is provided, which is displaceable longitudinally by means of an adjustmen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com