Induction heating device

A technology for induction heating devices and heated objects, which is applied in the direction of induction heating devices, induction heating, electric heating devices, etc., and can solve the problems of sensor 5 thermal responsiveness and temperature detection accuracy degradation, and inability to heat heated objects 2, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

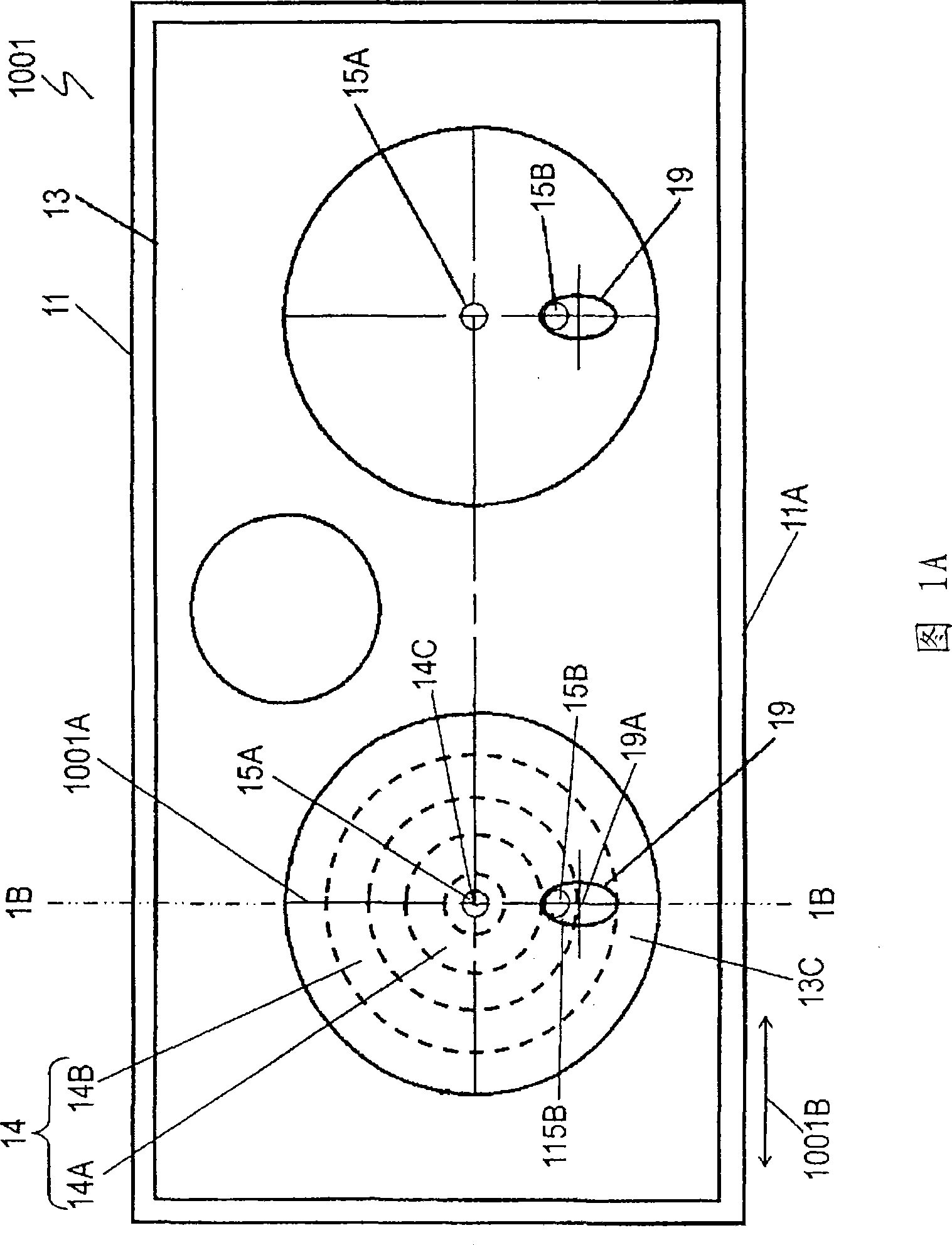

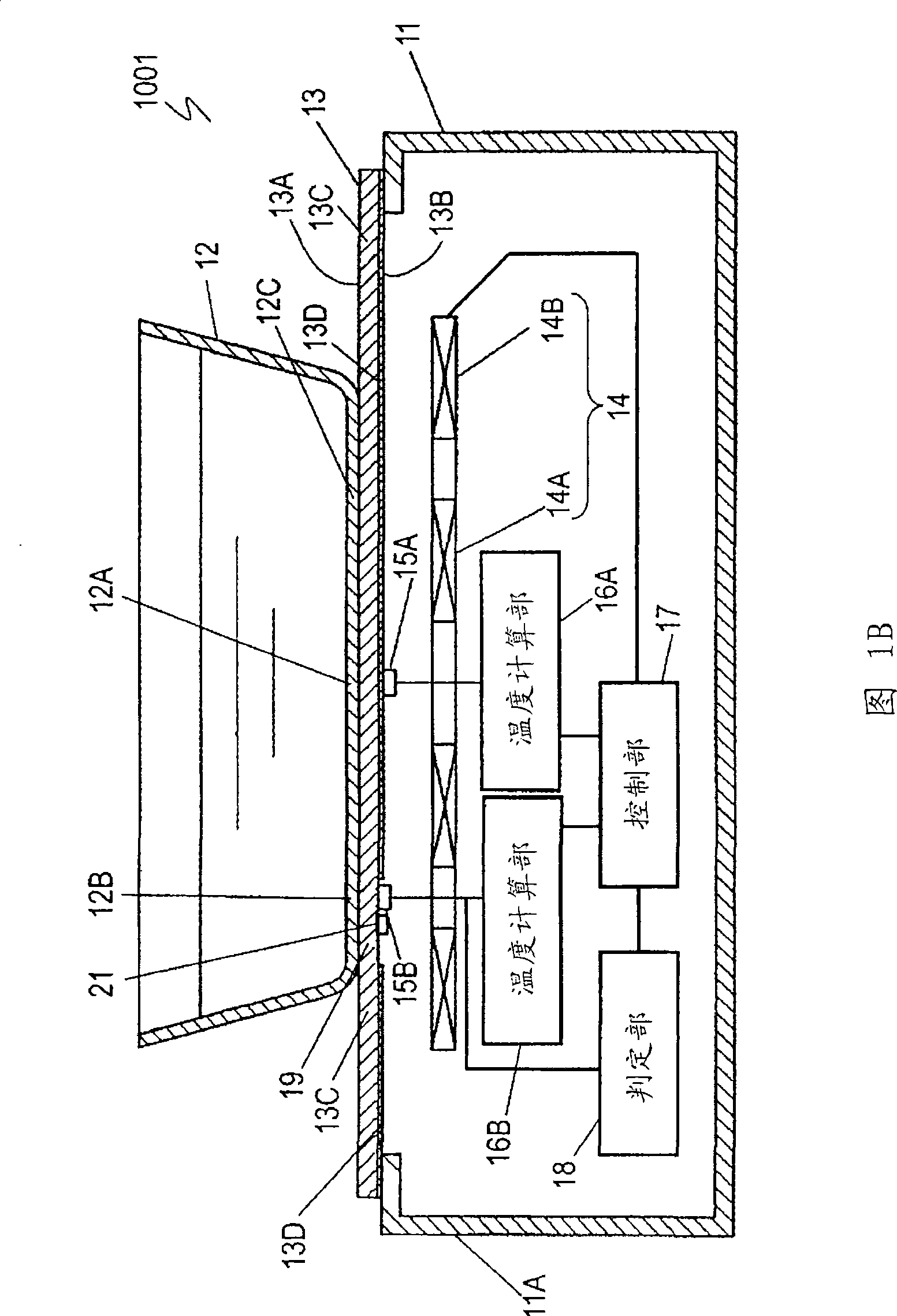

[0025] FIG. 1A is a top view of an induction heating device 1001 according to an embodiment of the present invention. FIG. 1B is a cross-sectional view of the induction heating device 1001 shown in FIG. 1A along line 1B-1B.

[0026] On the upper surface of the casing 11 is arranged a top plate 13 configured to place a heated object 12 such as a pan, and has an upper surface 13A and a lower surface 13B opposite thereto. A heating coil 14 for inductively heating the object 12 to be heated is disposed below the top plate 13 . The heating coil 14 is divided into an inner coil 14A and an outer coil 14B surrounding the inner coil 14A. The inner coil 14A and the outer coil 14B are electrically connected to each other. The entire bottom surface 12C of the object to be heated 12 can be uniformly heated by the inner coil 14A and the outer coil 14B. Contact heat-sensitive elements such as thermistors, that is, sensors 15A and 15B are arranged on the lower surface 13B of the top plate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com