Grommet

A grommet and fitting hole technology, applied in electrical components and other directions, can solve the problems of low insertion force, time-consuming, unstable installation posture, etc., and achieve the effects of equal fixing force, rotation prevention, and reliable positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

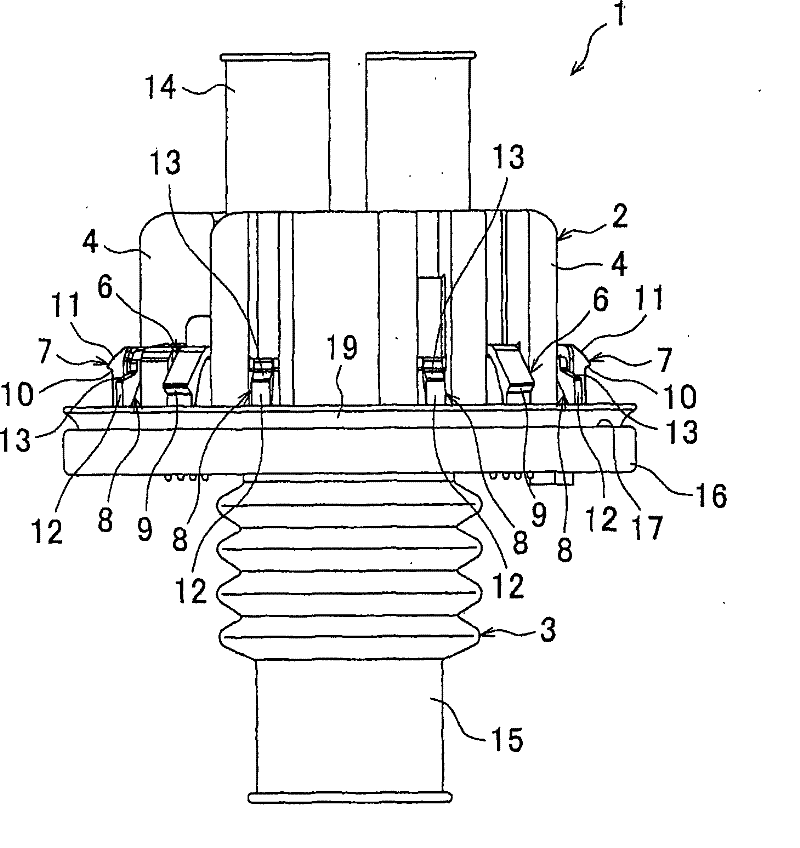

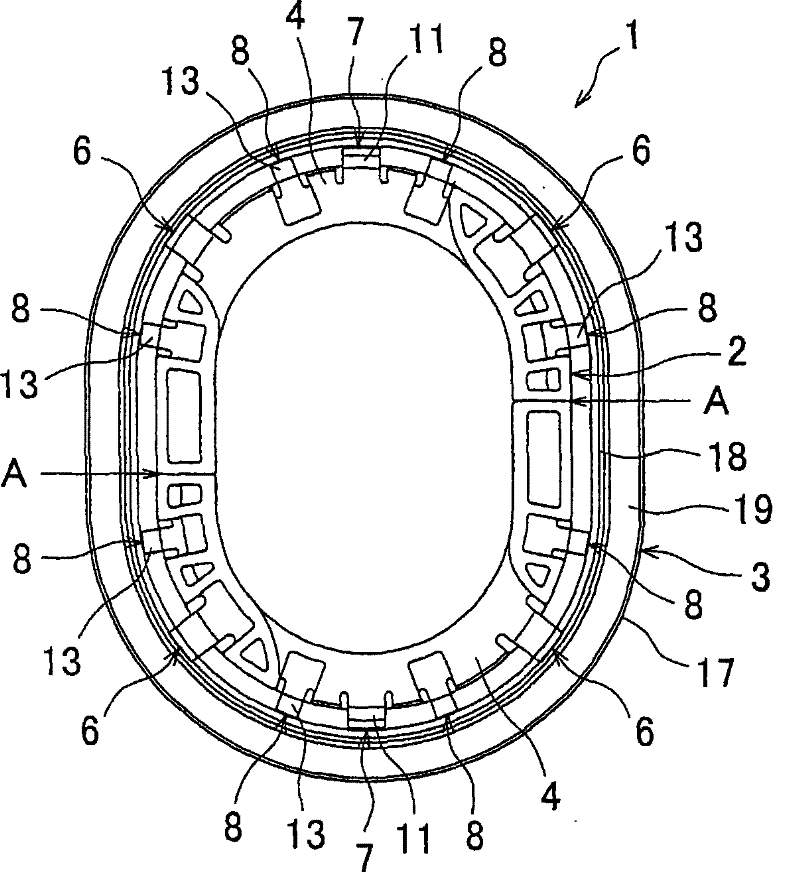

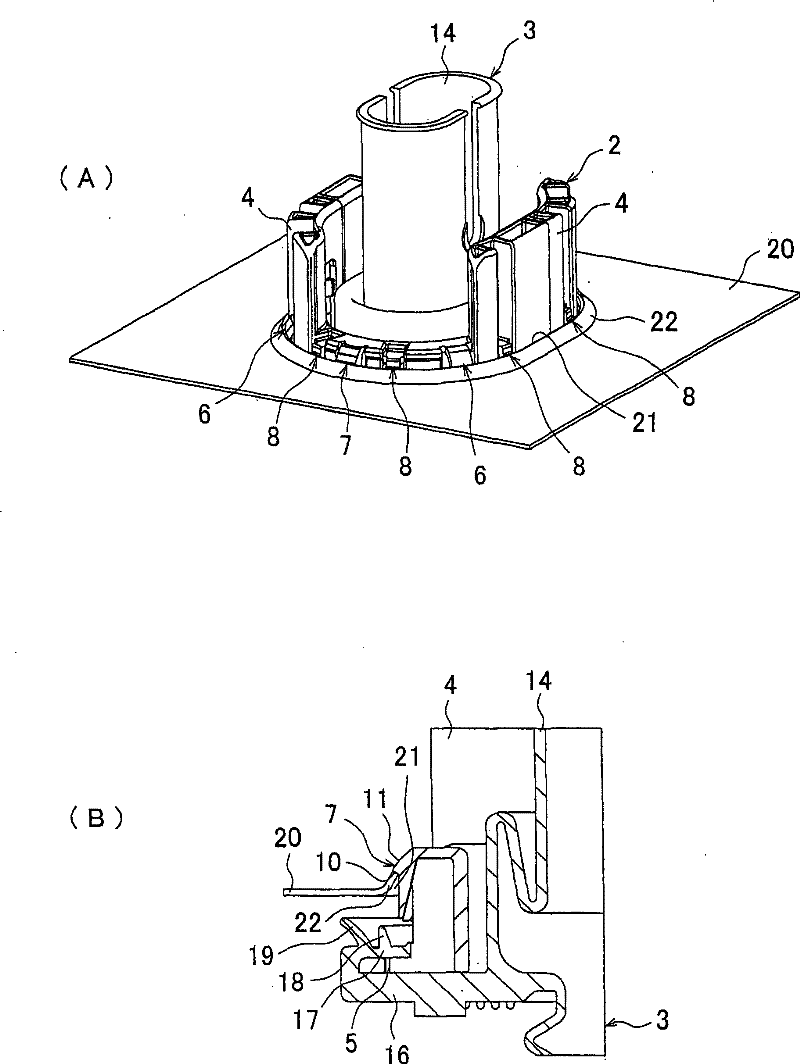

[0034] Embodiments of the present invention will be described below based on the drawings.

[0035] figure 1 is a side view showing an instance of a grommet, figure 2 It is a plan view, and the grommet 1 is composed of a hard grommet inner cylinder 2 made of synthetic resin and a soft grommet outer cylinder 3 made of rubber. First, the grommet inner cylinder 2 is an oblong cylindrical body in plan view that fits into the fitting hole of the mounting plate described later, and the surface in the minor axis direction ( figure 2 The position A) is divided into two split bodies 4, 4, and the locking piece (not shown) protruding from the split surface of the split body 4 on one side is inserted into the recess and set on the other side In the concave portion (not shown) of the split surface of the split body 4, a combined structure is formed. Label 5 is the flange part (as image 3 , 4 shown).

[0036]In addition, two locking claws 6 as locking portions, one temporary fixin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com