Cold roll forming and virtual manufacturing system based on CATIA

A virtual manufacturing system and cold bending technology, applied in the direction of digital control, comprehensive factory control, electrical program control, etc., can solve problems such as delaying the time when equipment is put into production, affecting the quality of pass design and manufacturing, and scrapping rolls.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

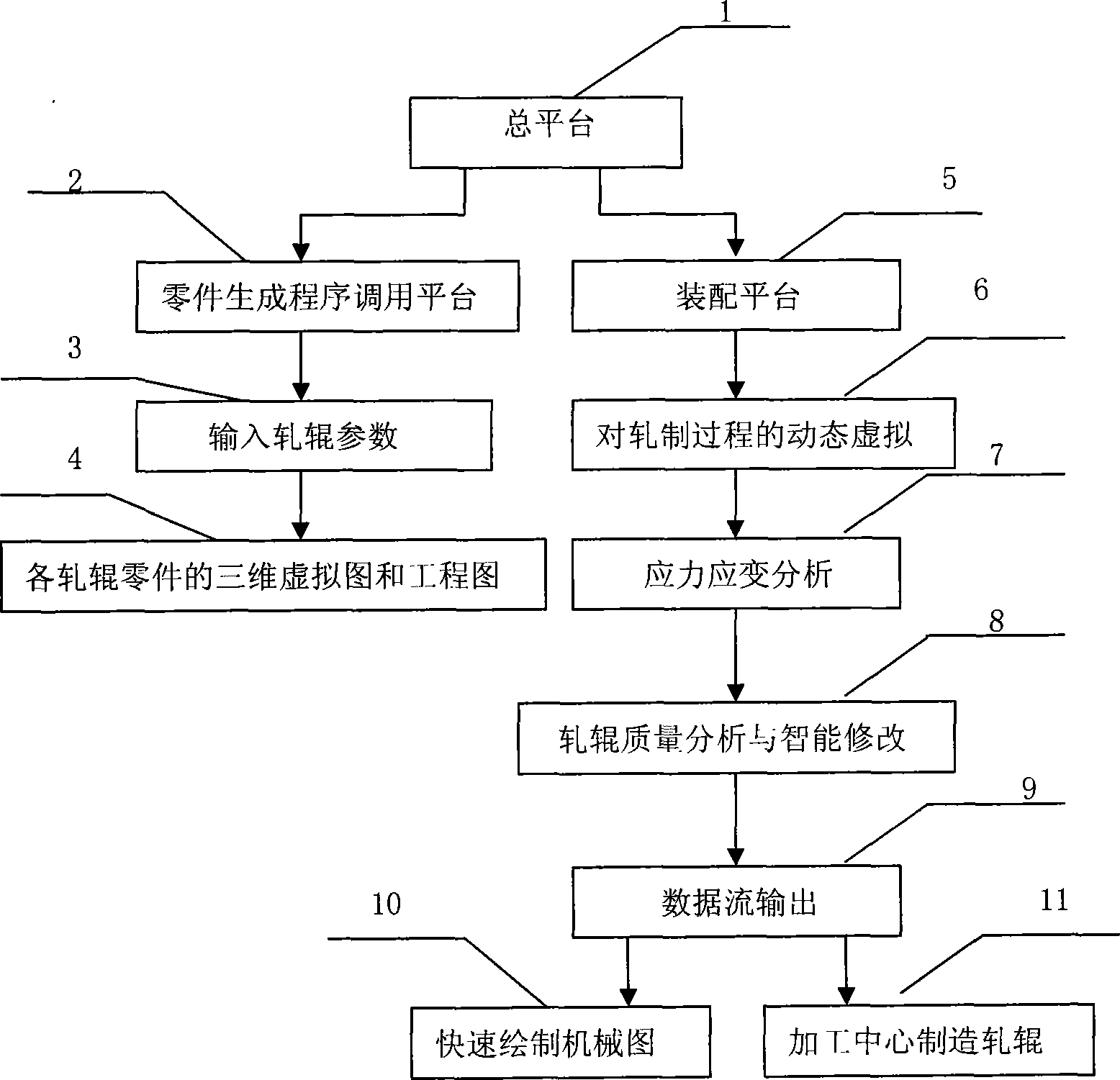

[0016] The first is to establish the main platform interface, the total platform has two links: 1. Parts generation program calling platform; 2. Assembly platform. The function of the part generation program call platform is to provide the parameter input window for the shape of the same item of the roll and each feature point. The user can call out the required virtual roll and input the corresponding parameters to obtain the three-dimensional virtual map of the roll, and can also Obtain an engineering drawing of the roll.

[0017] The functions of the assembly platform are: receiving the three-dimensional space position of the roll, assembling and virtual dynamic rolling process, analyzing the stress-strain data of each roll system, balancing and correcting the stress of each roll, and finally giving the manufacturing data flow of each roll.

[0018] Compared with the prior art, the present invention has the following advantages: 1) establishes a virtual system of the total ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com