Method of preventing generation of heavy ingredient of methyl ethyl ketone

A butanone and heavy technology, which is applied in the separation/purification, fractionation, organic chemistry, etc. of carbonyl compounds, can solve the problems of increasing heavy components and failing to meet product specifications, and achieve the effect of preventing dimerization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The best way to practice the invention

[0023] The method for preventing the production of heavy components of methyl ethyl ketone according to the present invention is characterized in that a dimerization-preventing material is used on at least the surface in contact with methyl ethyl ketone in the purification facility or storage facility of methyl ethyl ketone.

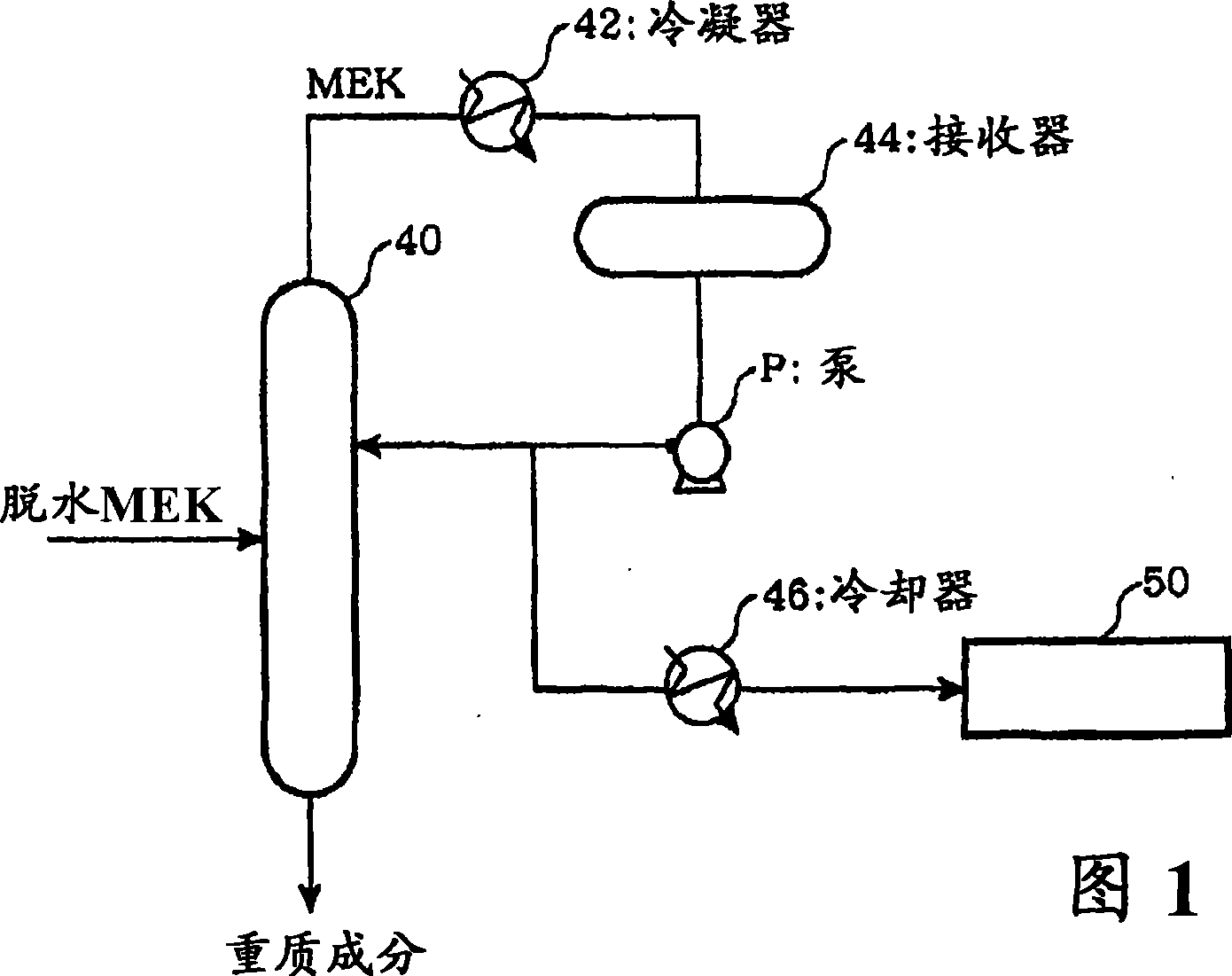

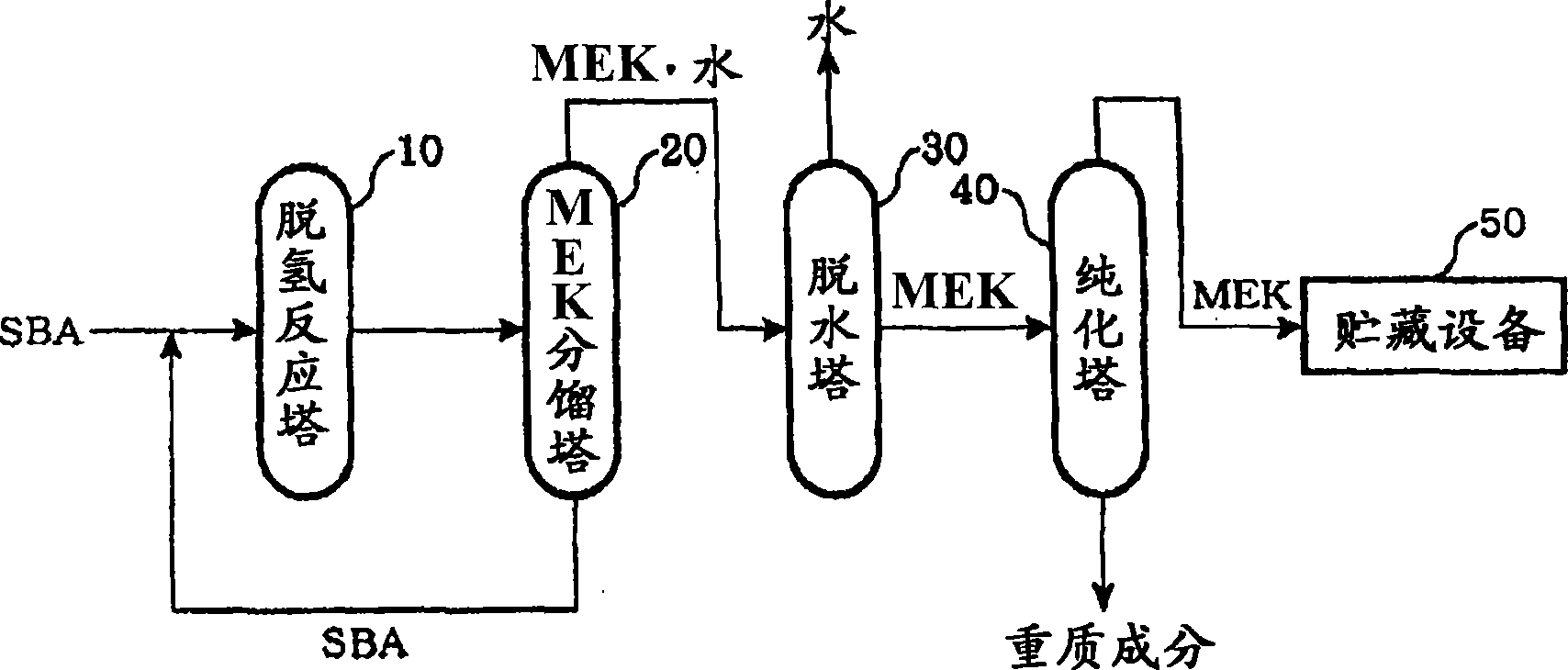

[0024] Fig. 1 is a schematic flow chart showing the purification steps of methyl ethyl ketone. Figure 1 shows the figure 2 The dehydration column 30 is shown as a purification step of butanone dehydrated.

[0025] The dehydrated methyl ethyl ketone is distilled through the purification tower 40 and recovered in the form of gas from the top of the tower. The gaseous methyl ethyl ketone is cooled and liquefied by the condenser 42 and stored in the receiver 44 . The methyl ethyl ketone accumulated in the receiver 44 is sent again to the purification column 40 as needed, and heavy components are removed unti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com