Filler neck

A technology of filling pipes and oil guns, which is applied in the layout, power plant, transportation and packaging combined with the fuel supply of internal combustion engines, can solve the problems of complex structure and high air tightness, and achieve the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Next, one embodiment of the present invention will be described based on examples.

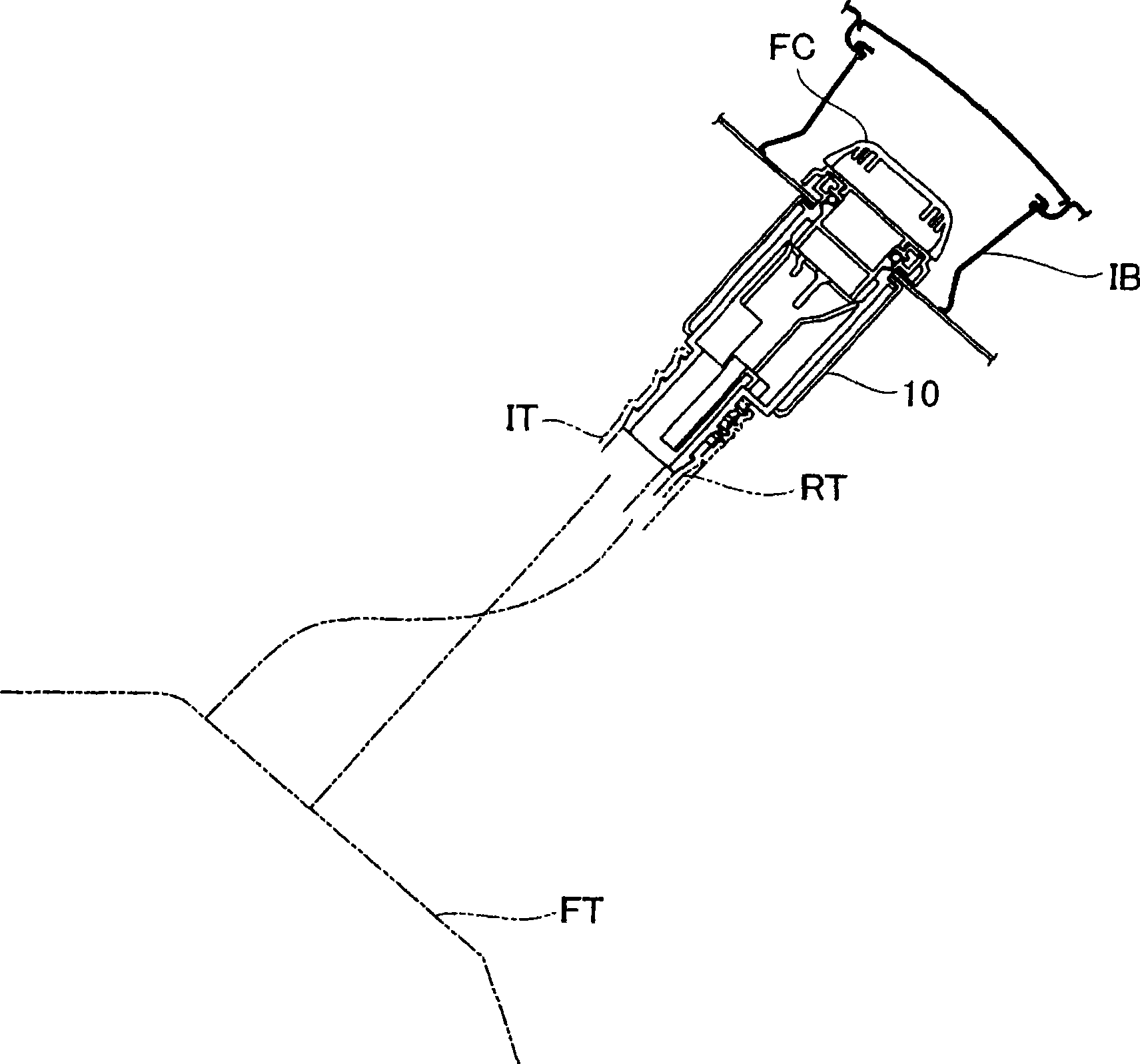

[0028] (1) Outline structure of oil supply device

[0029] figure 1 It is a schematic configuration diagram showing a fuel supply device using a filler nozzle 10 according to an embodiment of the present invention. Such as figure 1 As shown, the filler nozzle 10 is disposed between the fuel inlet tank IB and the fuel tank FT, and delivers fuel supplied from a fuel supply gun (not shown) to the fuel tank FT. The filling port of the filler nozzle 10 is opened and closed by the fuel cap FC, and the downstream side of the filler nozzle 10 is connected to the fuel inlet pipe IT and the circulation pipe RT. The fuel inlet pipe IT conveys the fuel sprayed from the fuel supply gun from the fuel filler nozzle 10 to the fuel tank FT. The circulation pipe RT constitutes a part of a circulation passage which allows the fuel vapor-containing air of the fuel tank FT supplied with fuel to escape f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com