Security separator for bracket tray

A separator and safe technology, applied in the direction of conveyor objects, transportation and packaging, storage devices, etc., can solve problems such as inability to take out goods, avoid the influence of accumulation pressure, and improve convenience and safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

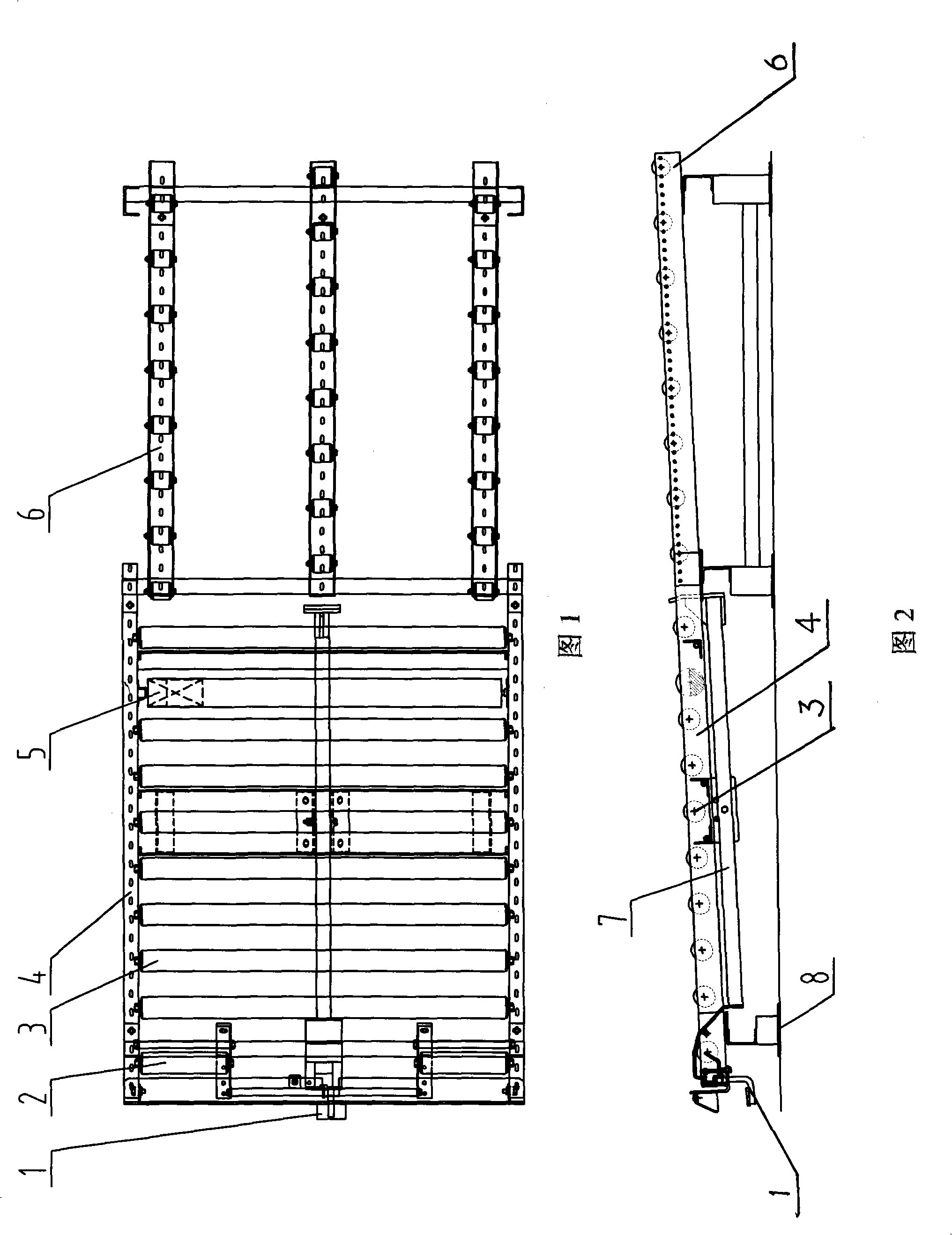

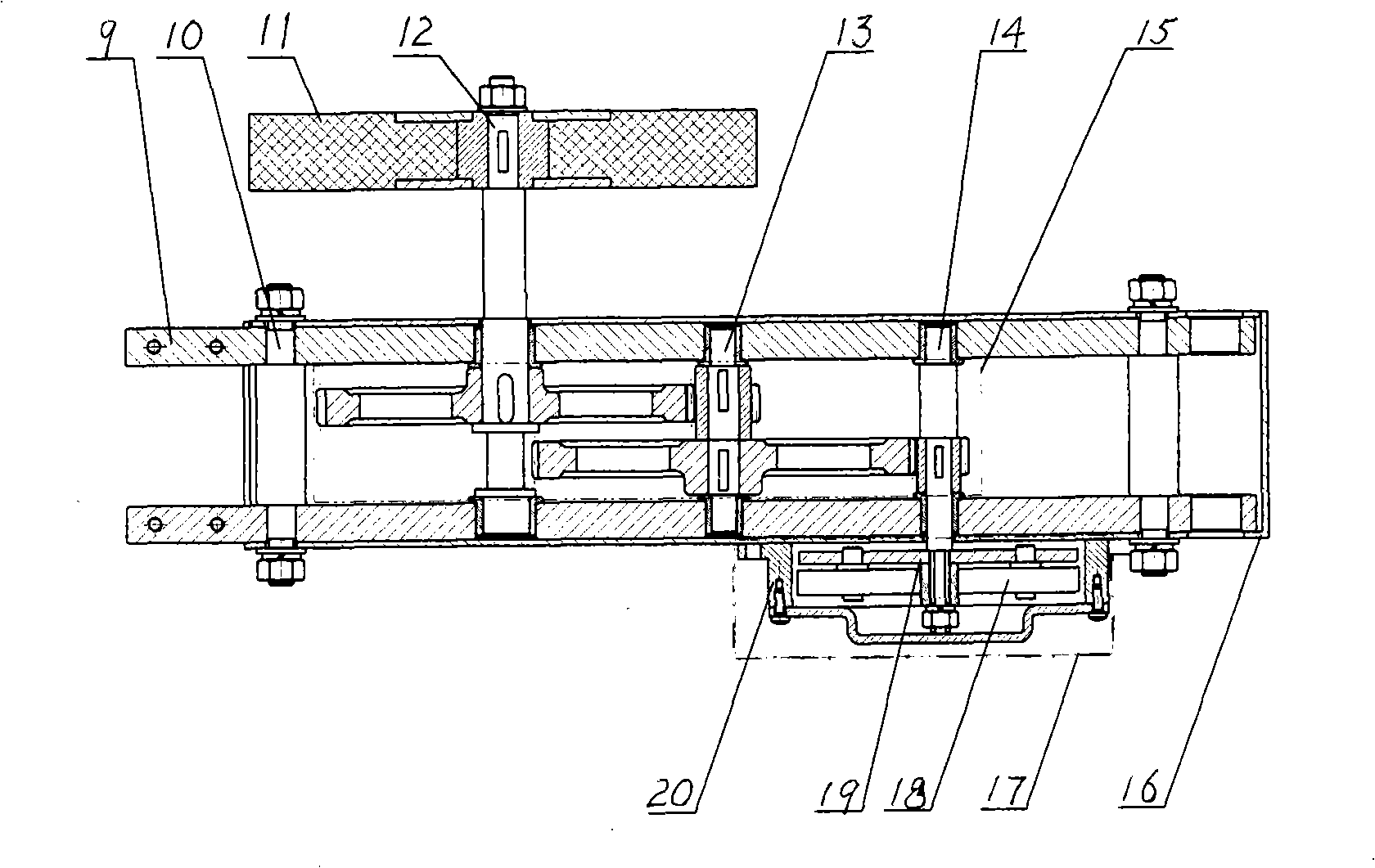

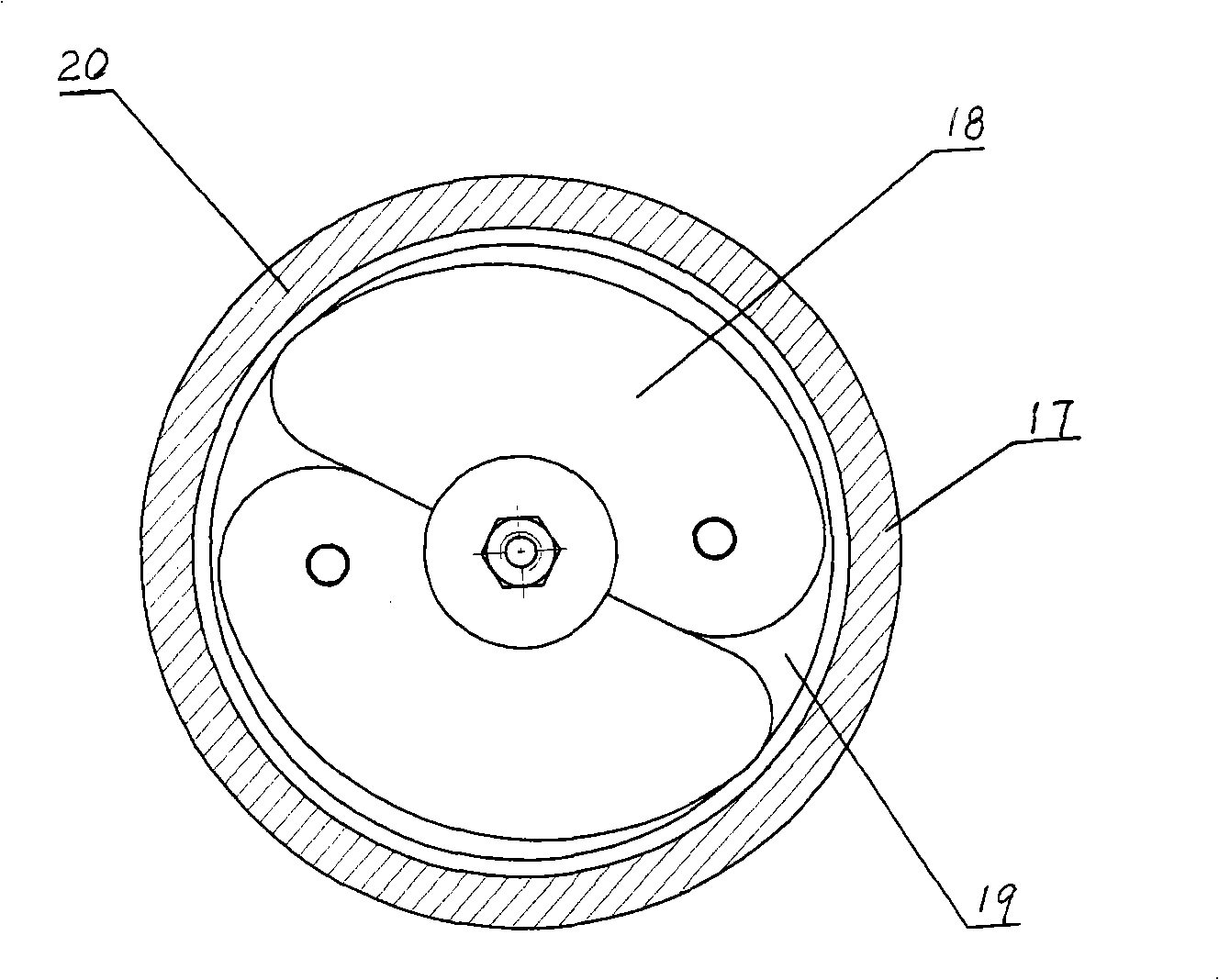

[0017] As shown in Figures 1 and 2, it is a schematic structural diagram of a pallet safety separator. The pallet safety separator is composed of a hook mechanism 1, a short roller 2, a long roller 3, a conveying roller table 4, a speed reduction mechanism 5, The shelf roller table 6, the blocking mechanism 7 and the base 8 are composed.

[0018] The conveying roller table 4 is connected to the shelf roller table 6, at least two long rollers 3 are arranged between the conveying roller table 4, and an upturnable blocking mechanism 7 is provided under the at least two long rollers 3, and one end of the blocking mechanism 7 Set between the shelf roller table 6 and the conveying roller table 4, the other end of the blocking mechanism 7 is located at the exit of the conveying roller table 4 and connected with the stepping hook mechanism 1, the stepping hook mechanism 1 passes the short roller 2 and the conveying rollers on both sides The road 4 is fixed, and the outlet end of the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com