Design implement method of wind-pipe support and connection piece thereof during producing ship

An implementation method and a technology of connecting parts, which are applied to ship components, ship construction, ships, etc., can solve problems such as error-prone and low efficiency, and achieve the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

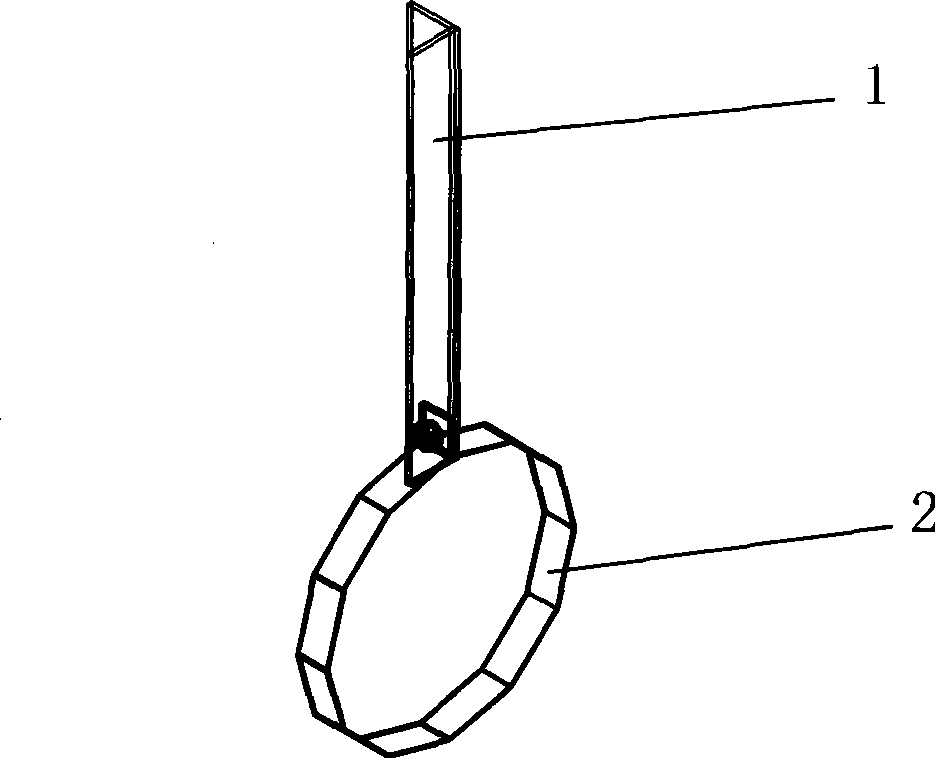

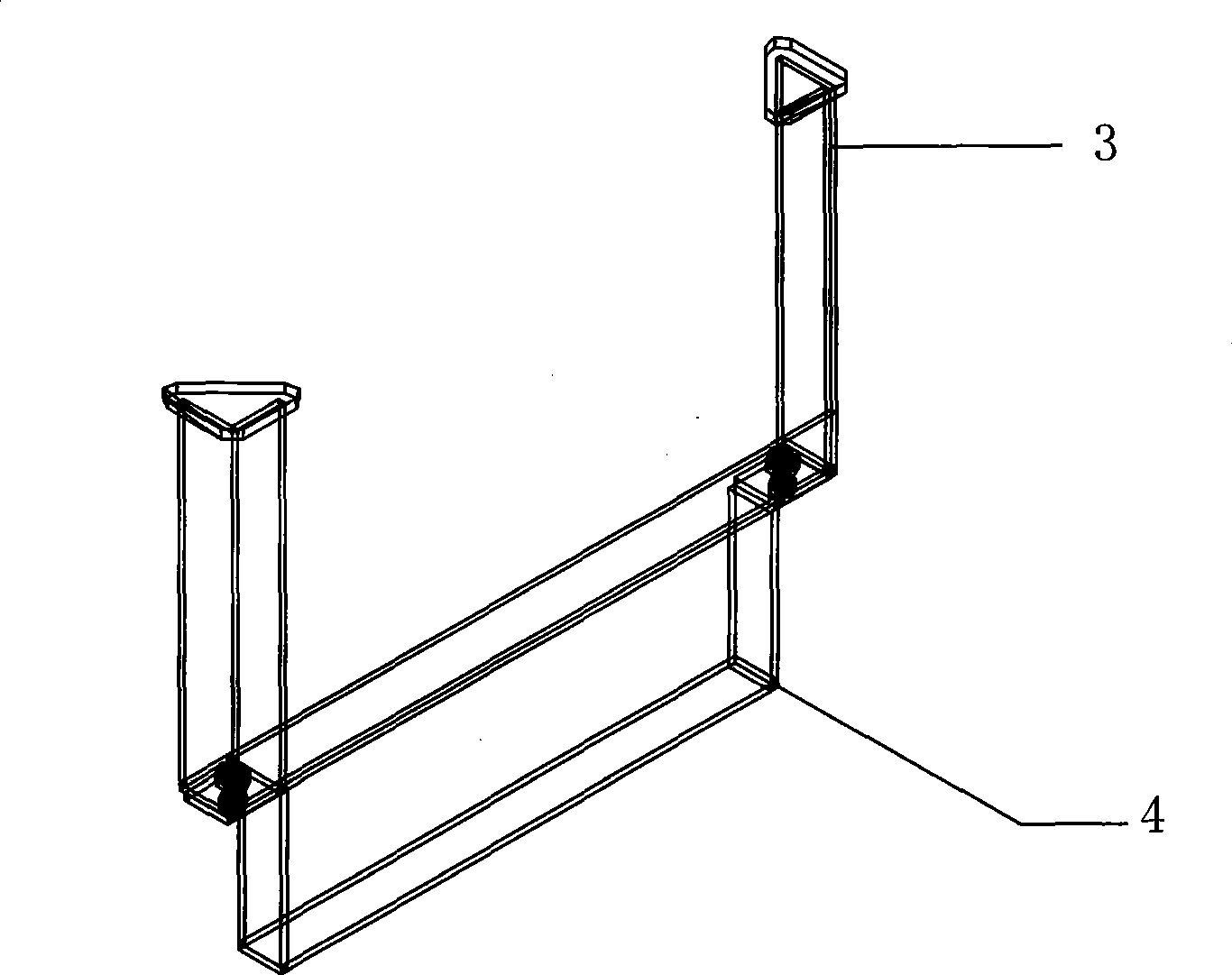

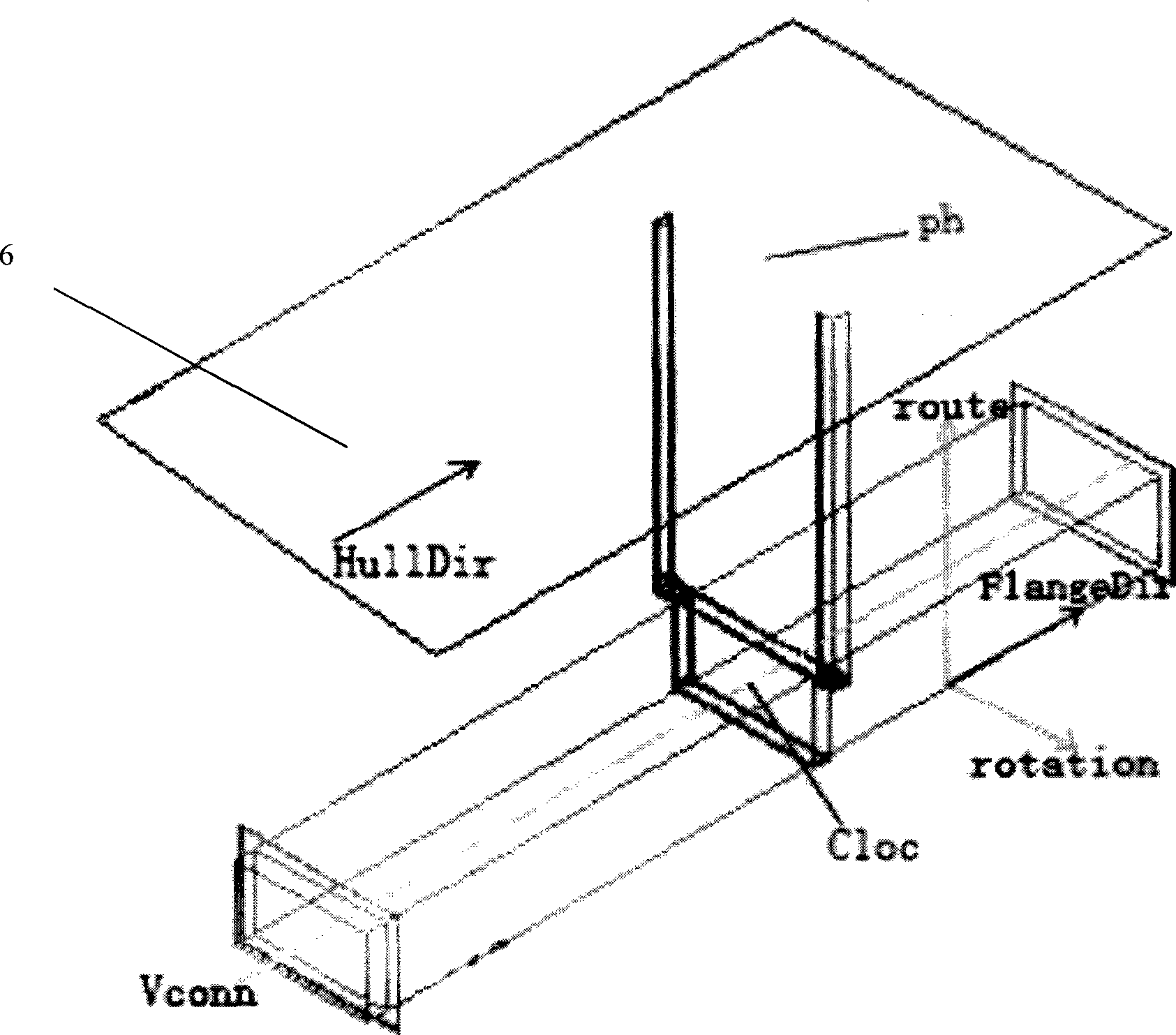

[0011] Reference attached figure 1 -4 illustrates a method of the present invention to realize the automatic design and modeling of the air duct support and its connectors on the hull structure. This method can be refined into the following implementation steps one by one:

[0012] (1) Realize the establishment of different types and different types of bracket models, and form a model database:

[0013] The air duct support model includes two types: the spiral air duct support model and the square air duct support model. With the different diameters of the air duct, the spiral air duct support has changes in specifications, materials, angle steel direction, gasket selection and whether the end is cut, and the shape is basically the same; while the square air duct support has many types, there are more than a dozen, corresponding The hoop material of the square air duct also needs to be changed as the diameter of the square air duct becomes larger; at the initial stage of des...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com