Calibration stand and calibration method for SF6 gas density and pressure monitoring device

A technology for monitoring device and gas density, which is applied in the field of calibration platform of SF6 gas density-pressure monitoring device, which can solve the difficulty of disassembling and assembling the primary charging interface and the secondary wiring interface, difficult calibration, and the inability to check the temperature of the density relay Compensate performance and other issues to achieve the effect of friendly operation control interface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0054] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific examples.

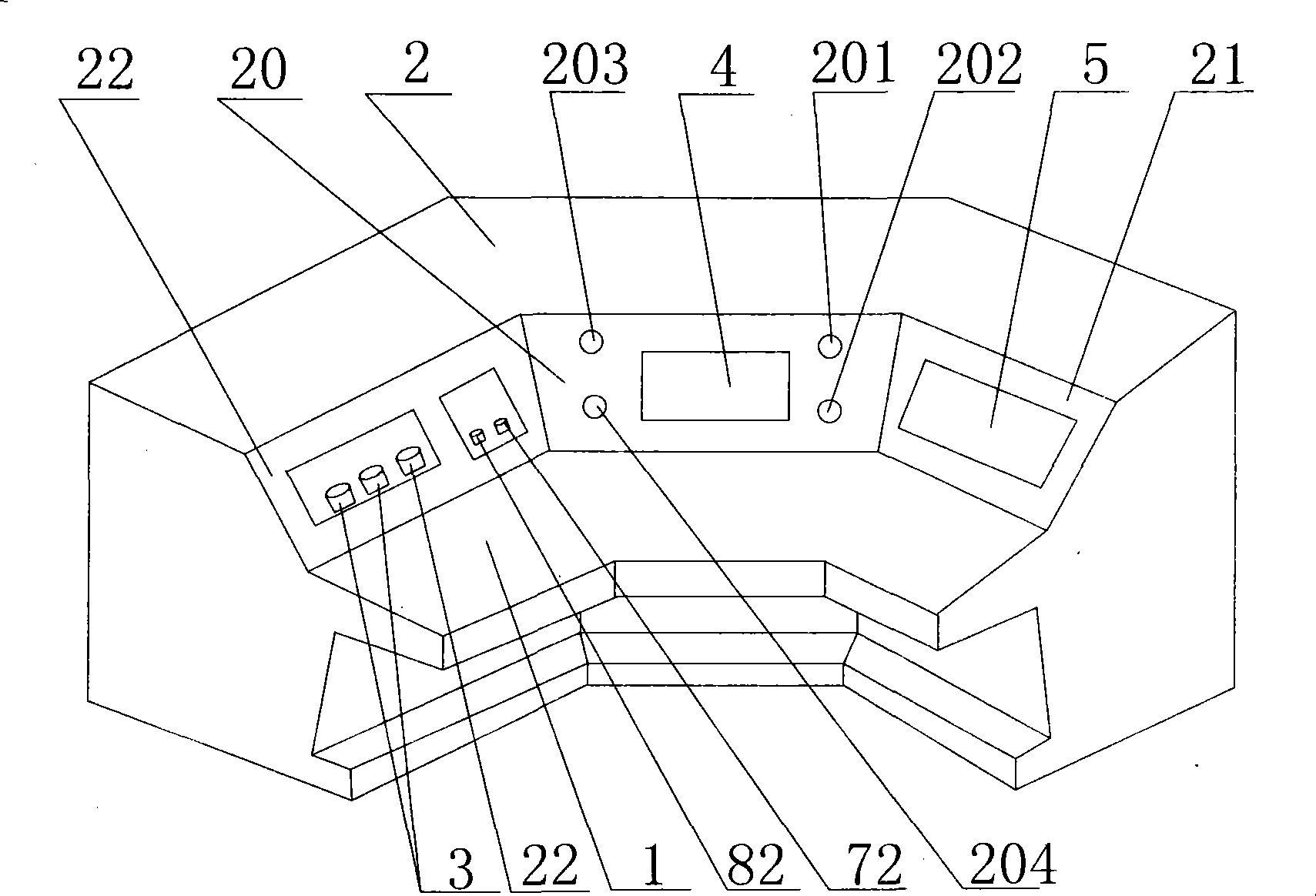

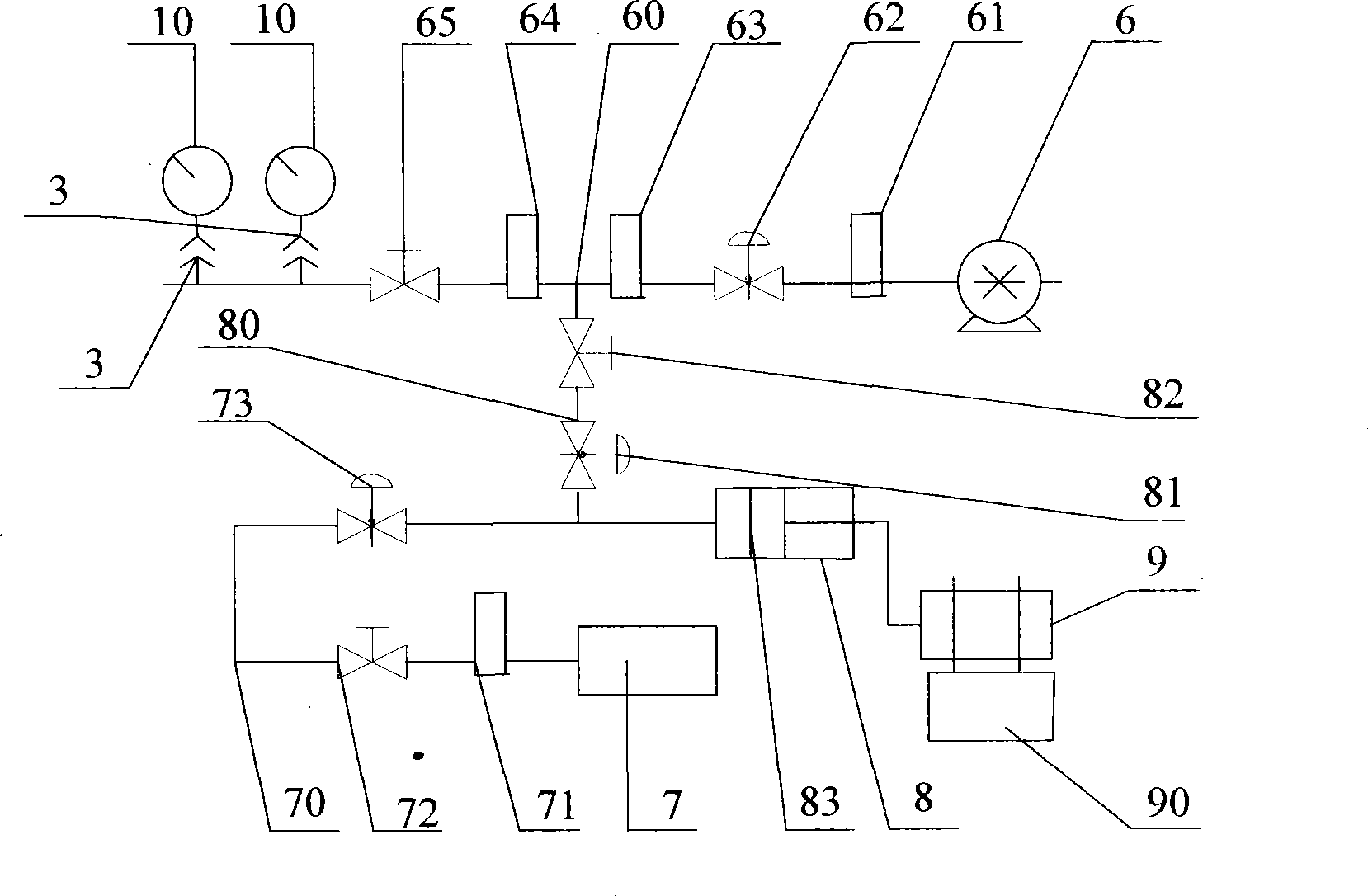

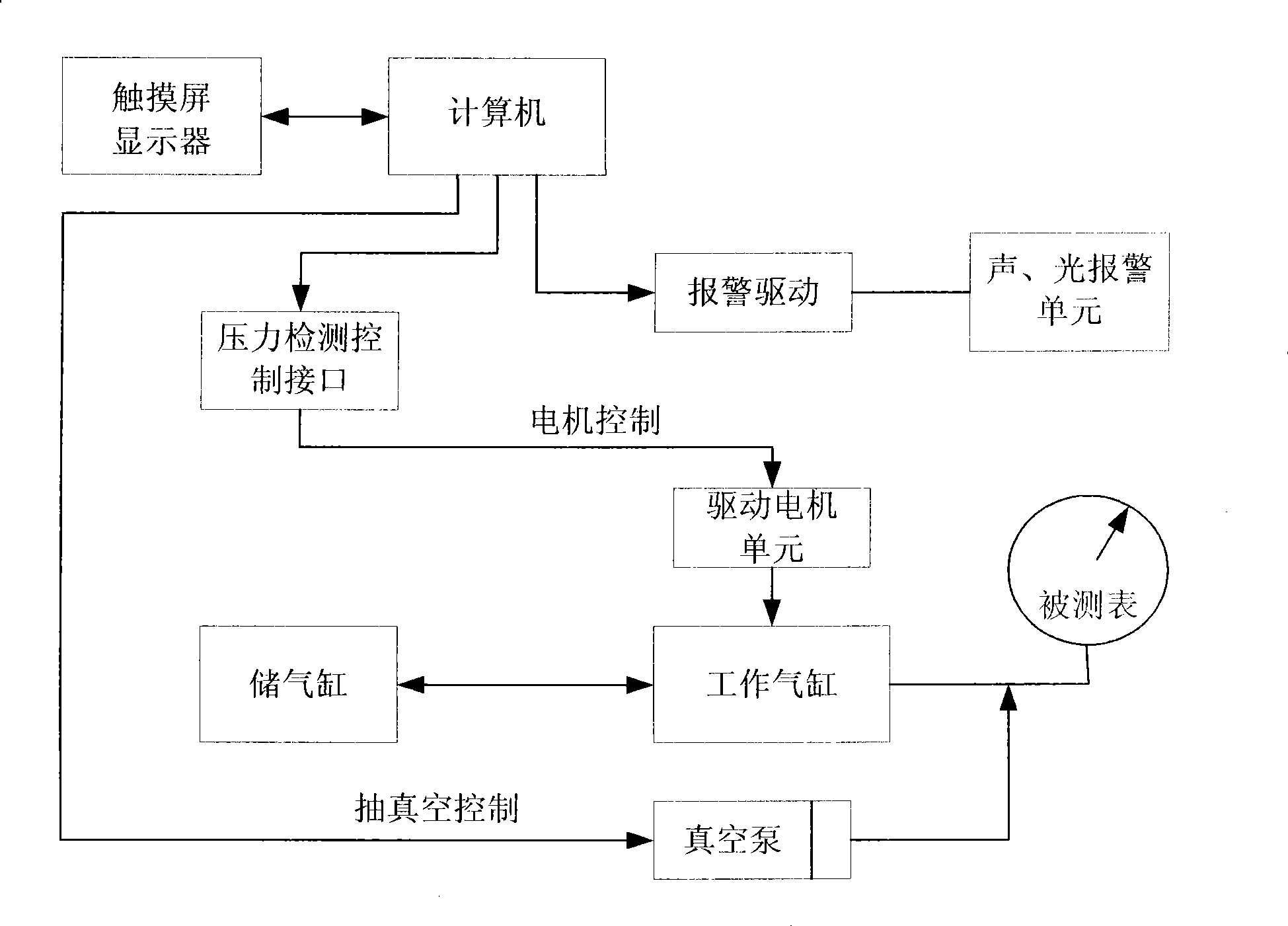

[0055] see figure 1 , the inventive SF 6 The calibration platform of the gas density-pressure monitoring device includes a high and low temperature box (not shown in the figure), an operation console 1, an operation cabinet 2 connected to the rear end of the operation console 1, and a host computer arranged on the operation cabinet 2, The mainframe consists of several SFs under test connected in parallel 6 Interfaces 3 and 1 of the gas density-pressure monitoring device are connected to the measured SF 6 The gas path control system connected to the interface 3 of the gas density-pressure monitoring device 10, a computer, a touch screen 4 and a printer 5 connected to the computer; the touch screen 4 is arranged on the front panel 20 of the operation cabinet 2, This panel 20 is also provided with a power indicator light 201, a power swi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com