Forged steel Y type valve

A technology of valves and forged steel, applied in the field of forged steel Y-type valves

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

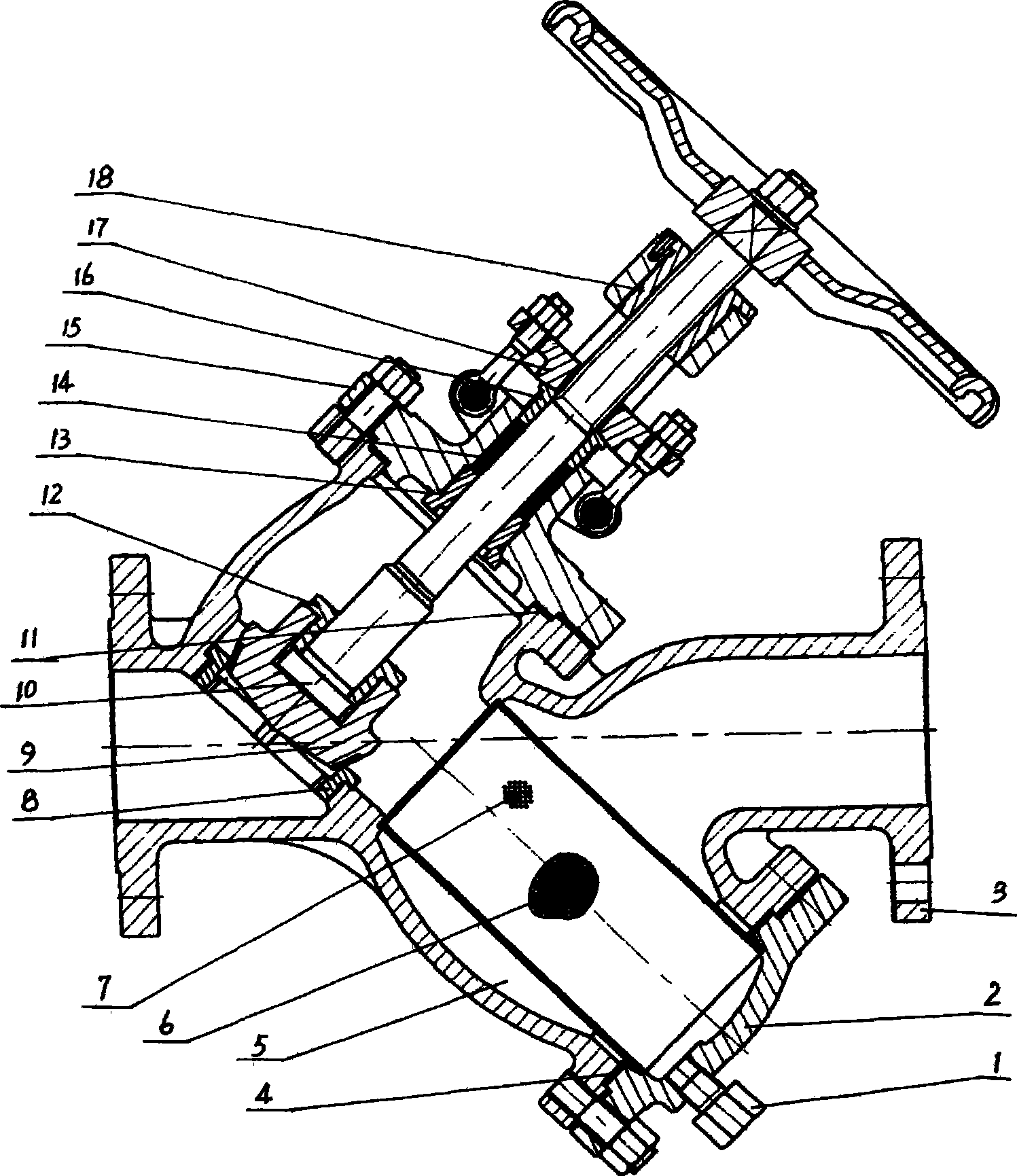

[0010] Such as figure 1 The forged steel Y-type globe valve shown includes a valve body 3, a valve seat 8, a valve cover 15, a valve disc 9, a valve stem 10, a transmission mechanism, seals and mounting parts, and a filter is provided in the outlet channel of the valve body 4. The filter device is composed of a filter chamber 5 communicated with the outlet channel, a filter screen 6 installed in the filter chamber 5 and a filter chamber end cover 2. When the disc 9 is opened, the medium enters the filter screen 6 from the inlet channel of the valve body 3 through the valve seat 8 to be filtered, and then flows out from the outlet channel of the valve body 3, so that the outlet medium is purified and filtered. The filter screen 6 is made into a cylindrical shape by wire mesh, and a filter element 7 is set inside the wire mesh. The filter element 7 is a porous stainless steel cylinder with the same shape as the wire mesh, which is installed close to the wire mesh to increase the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com