Automatic checking method for dimension line marking error in engineering drawing

An automatic inspection and dimensioning technology, applied in the field of dimension line recognition, can solve the problems of missing dimensions, low efficiency of manual inspection, multi-standard, etc., and achieve the effect of improving design efficiency, saving manual inspection costs, and avoiding design errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

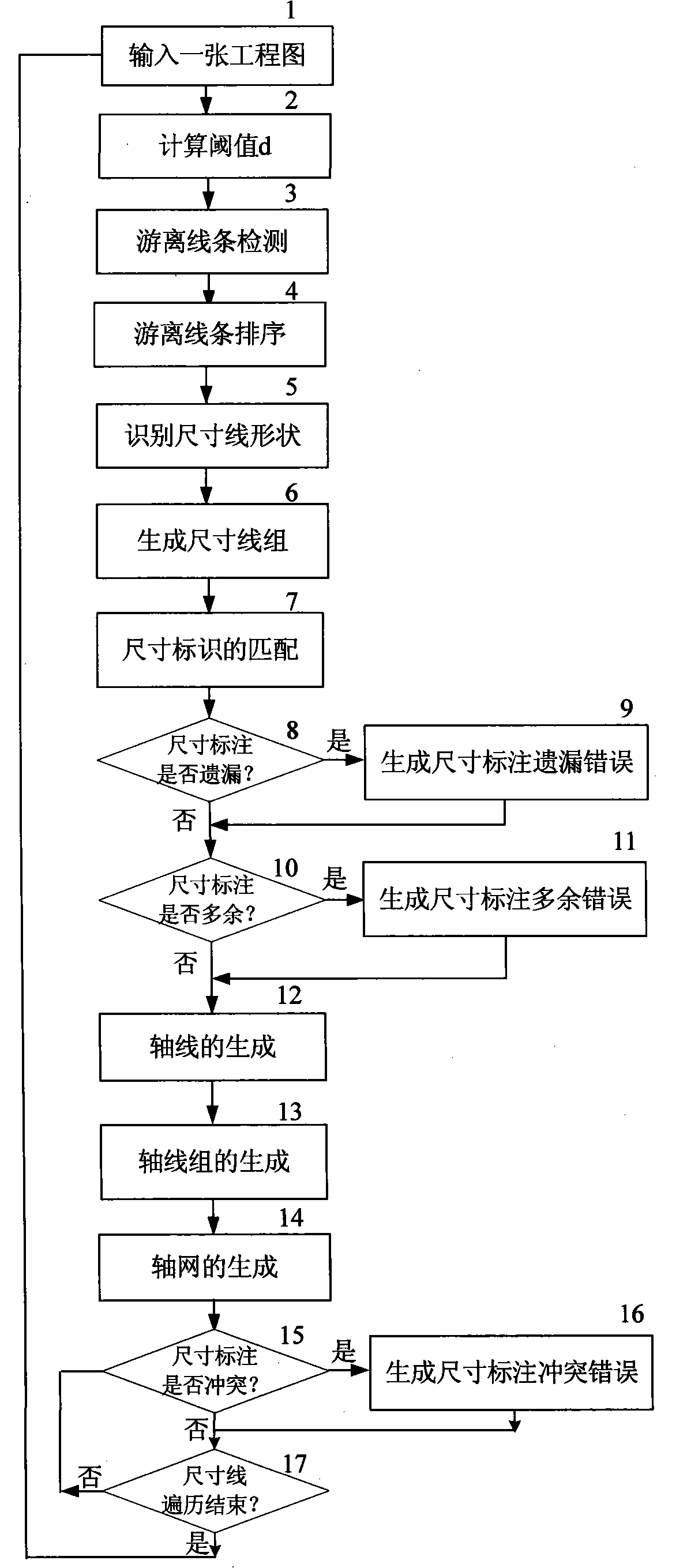

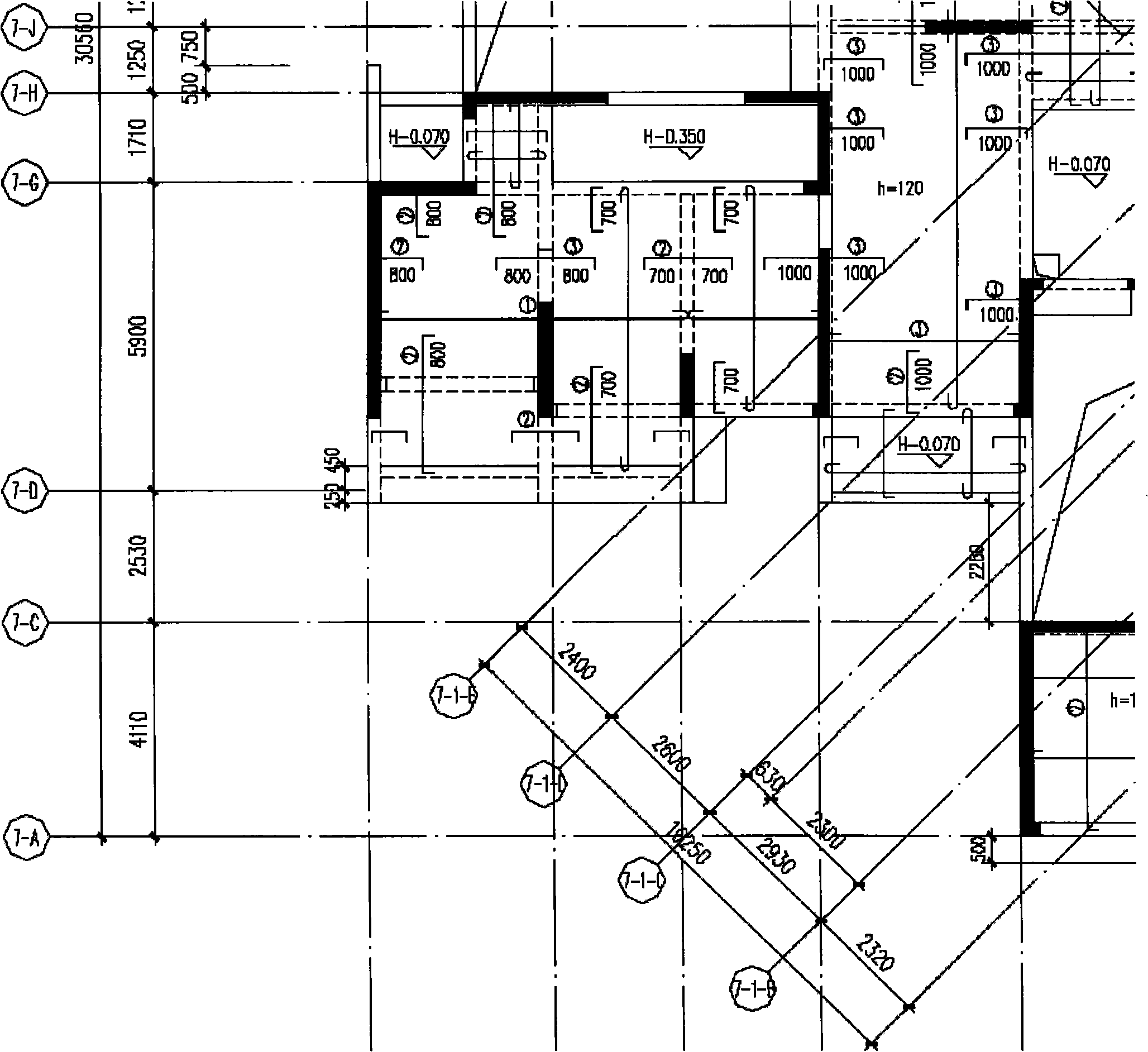

[0041] The inventive method such as figure 1 shown. figure 2 An example of an actual engineering drawing is given, in which there are a large number of scattered dimension lines to give precise dimensional descriptions of various engineering objects.

[0042] Step 1 Import a drawing with dimension lines.

[0043] The initial threshold d in step 2 is calculated according to the average height of strings in the engineering drawing;

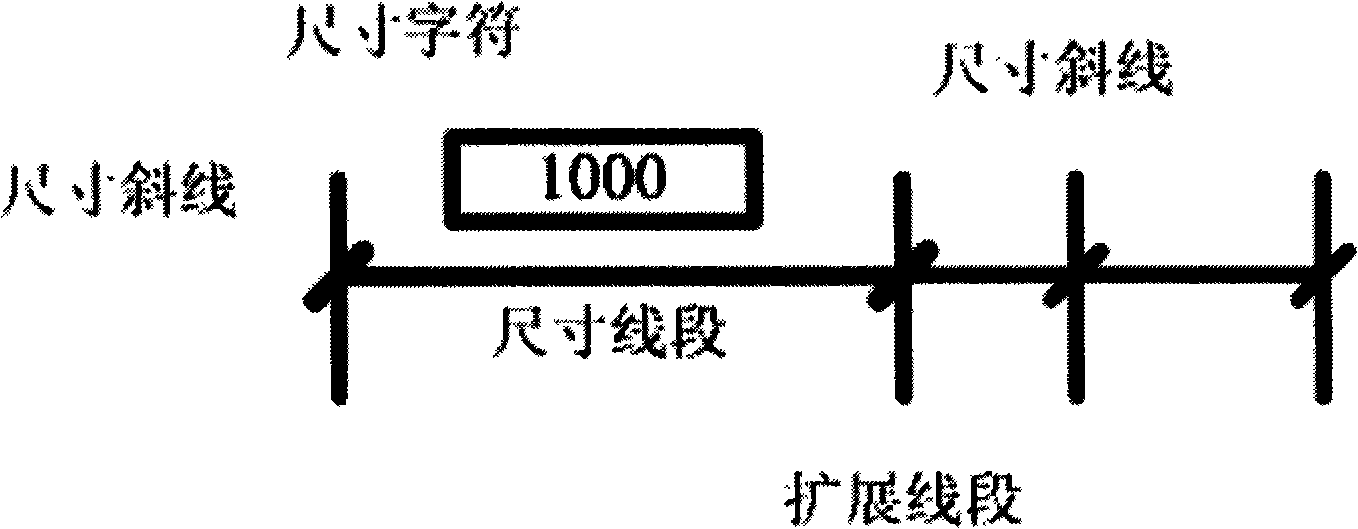

[0044] Steps 3-4 detect and sort stray lines in the drawing. The extraction of free lines in step 3 includes the following steps: (a) Check the endpoint connection of the straight line segment in the engineering drawing, if there is no intersecting line at the two ends, mark it as a free line, otherwise mark it as an excluded line ; (b) If the length of a free line is less than 0.5d, or greater than 3d, it will be marked as an excluded line; (c) if there is no vertical intersecting line in the middle of a certain free line, it will be marked as ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com