Absorbent, multilayered absorbent, and absorbent article

An absorbent, water-absorbing technology, applied in the direction of layered products, textiles and paper, non-woven fabrics, etc., can solve the problems of side leakage and easy flow of menstrual blood.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0091] Hereinafter, preferred embodiments of the present invention will be described with reference to the drawings.

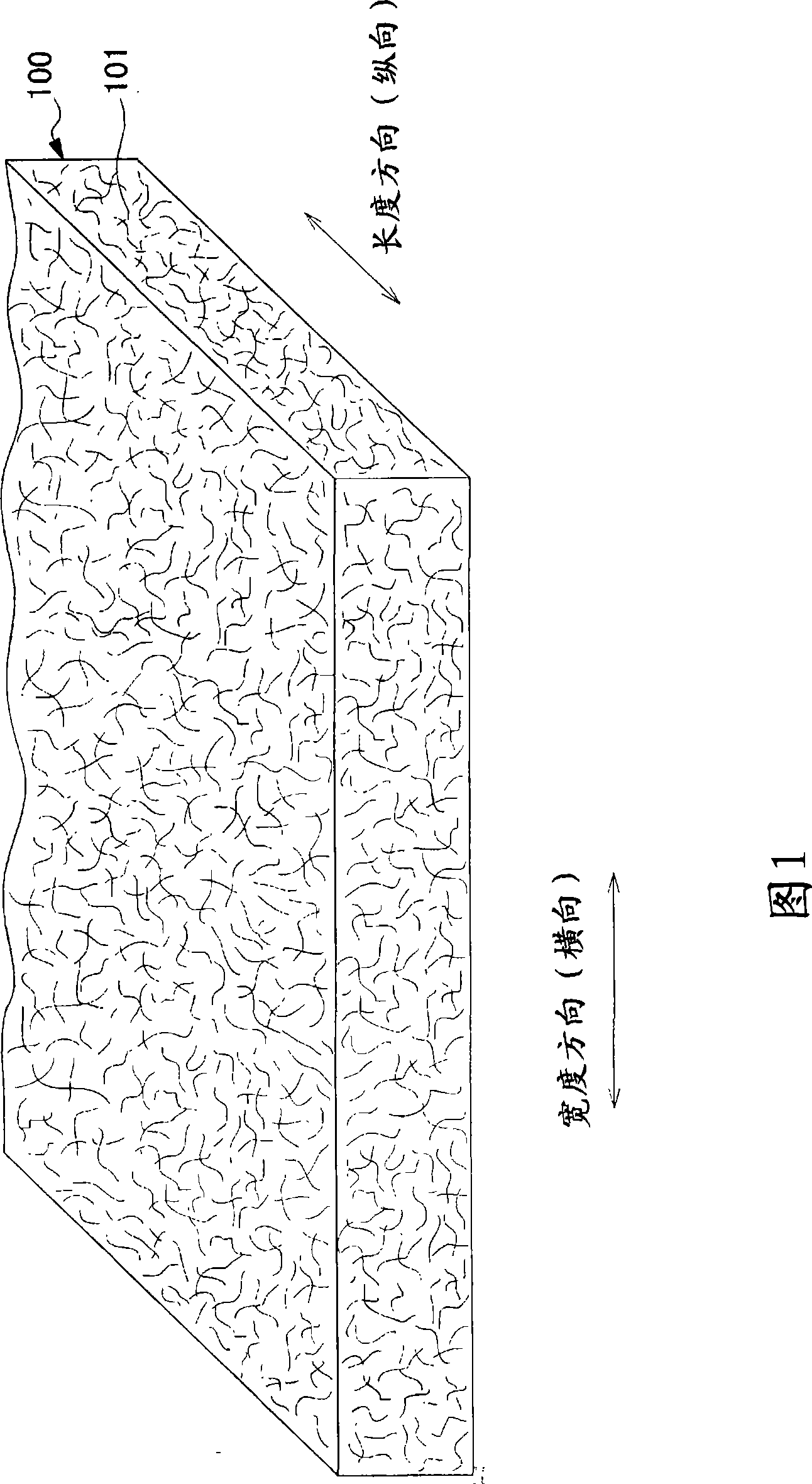

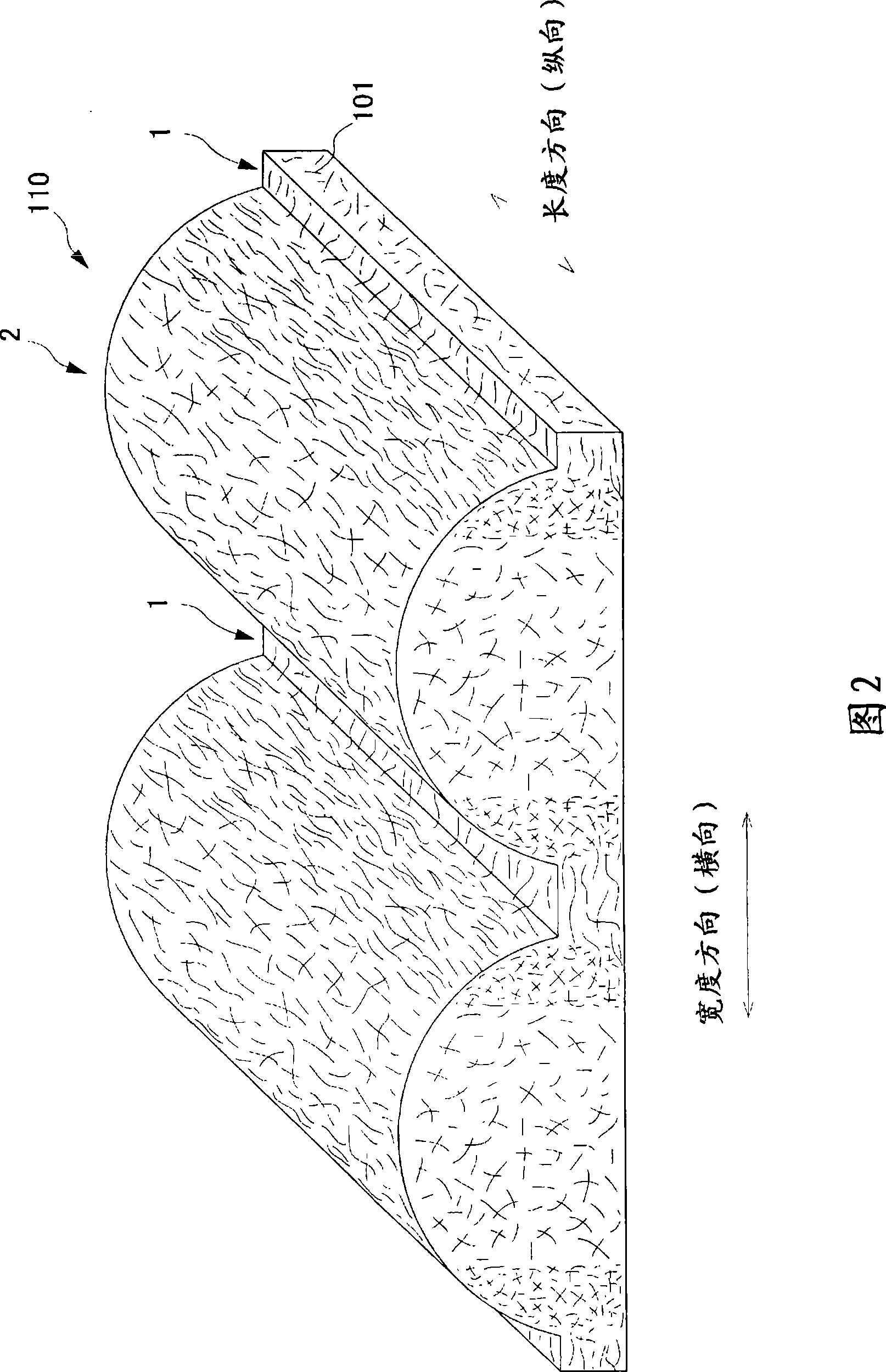

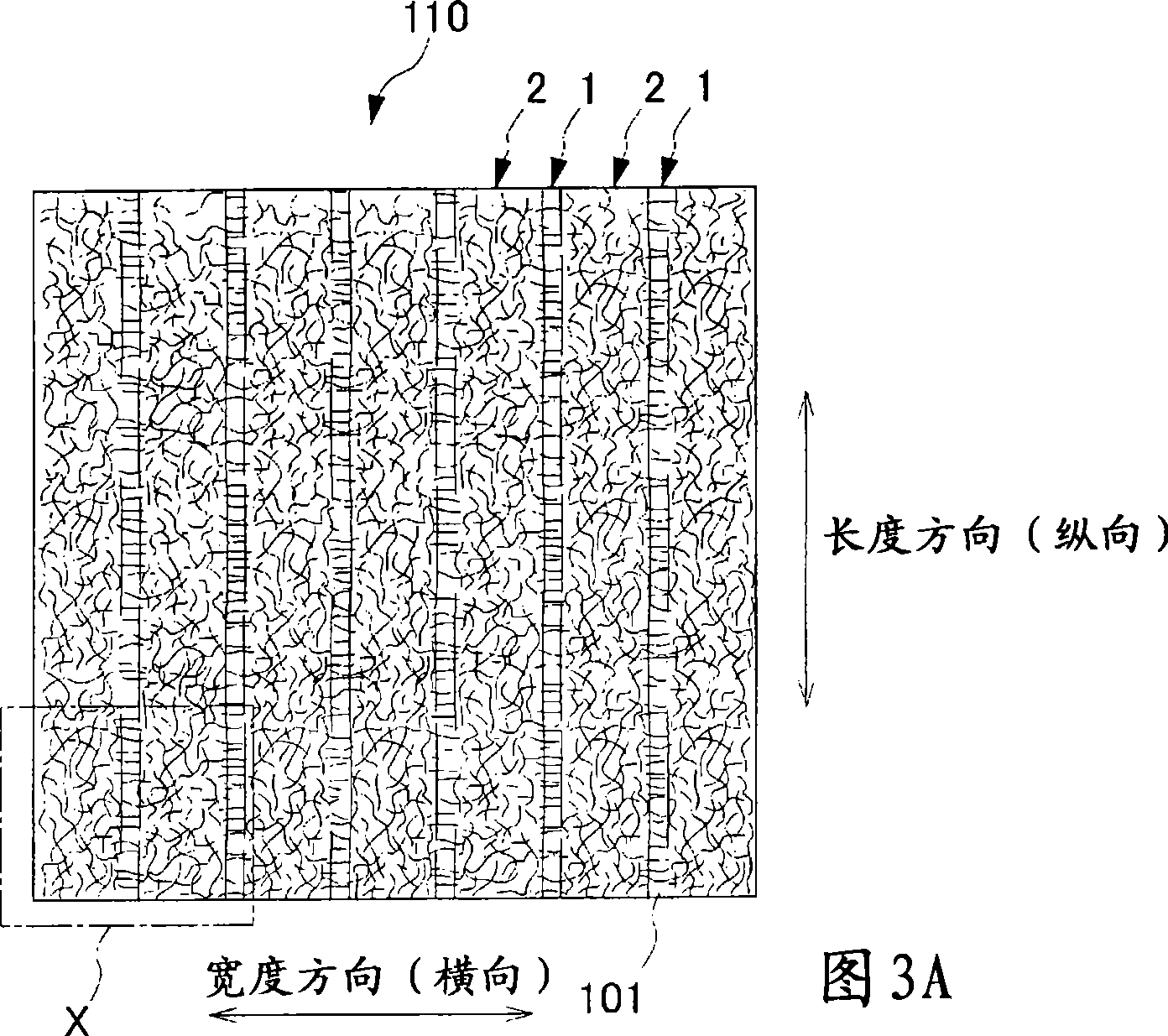

[0092] Fig. 1 is a perspective view of a fiber web. Fig. 2 is a perspective cross-sectional view of the absorber according to the first embodiment. Fig. 3A is a plan view of the absorber of the first embodiment. Fig. 3B is a bottom view of the absorber of the first embodiment. Figure 4A It is a plan view of the mesh support member. Figure 4B It is a perspective view of a mesh support member. Figure 5 is the fiber web of Figure 1 being Figure 4A and Figure 4B In a state in which the lower side is supported by the net-shaped support member, gas is sprayed toward the upper side to manufacture the absorbent body of the first embodiment in FIG. 2 . Fig. 6 is a side view illustrating an absorbent body manufacturing apparatus. Fig. 7 is a plan view illustrating an absorbent body manufacturing apparatus. Figure 8 is an enlarged perspective view of a region ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com