Automatic bolt tightening device

An automatic tightening device and bolt technology, applied in screwdrivers, power tools, wrenches, etc., can solve the problems of reducing work efficiency, time-consuming and laborious, and achieve the effect of flexible swing and convenient adjustment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The following embodiments are further descriptions of the content of the present invention as an illustration of the technical content of the present invention, but the essential content of the present invention is not limited to the following embodiments, and those of ordinary skill in the art can and should know any Simple changes or substitutions of the essential spirit of the invention shall belong to the protection scope required by the present invention.

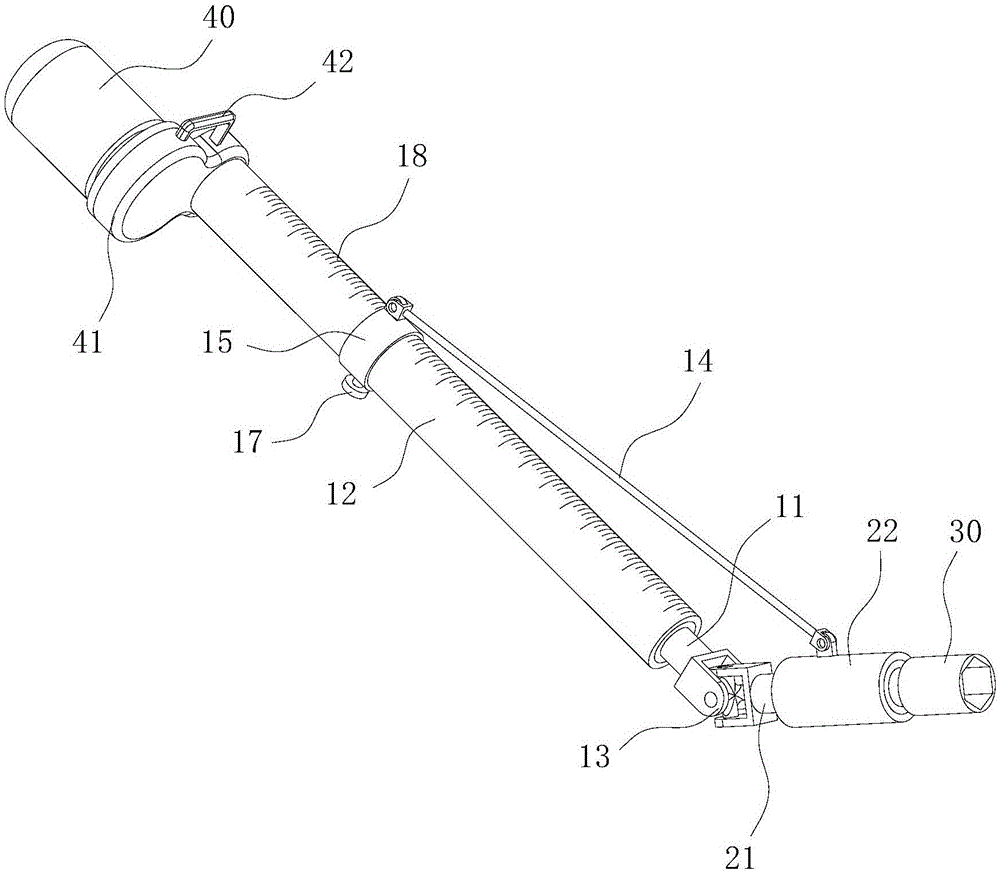

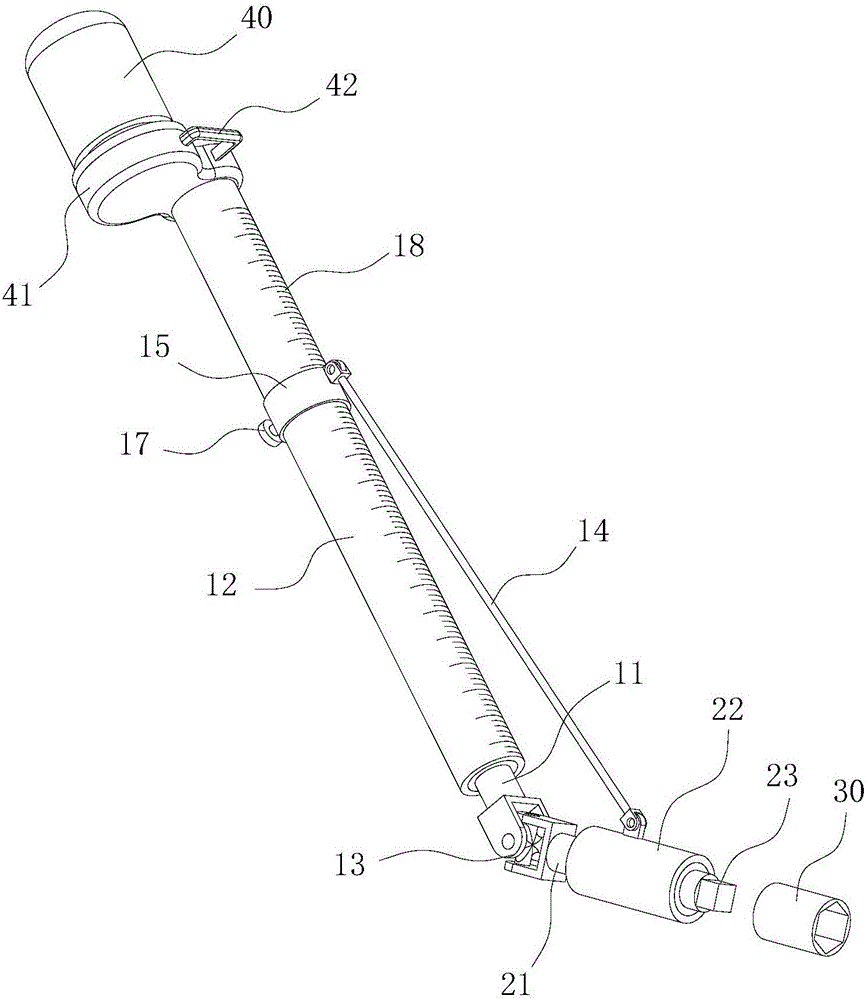

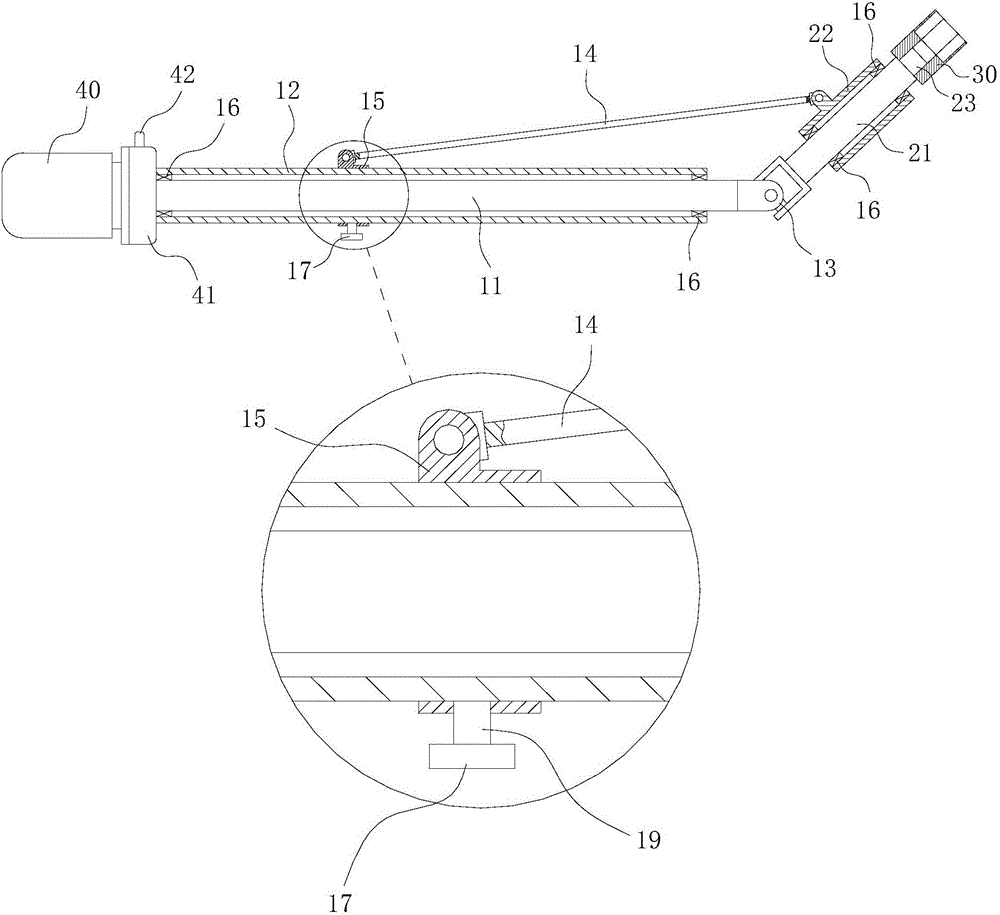

[0014] like Figures 1 to 3 As shown, an automatic bolt tightening device includes a first rotating shaft 11, a second rotating shaft 21, a first sleeve 12 and a second sleeve 22, and the first rotating shaft 11 and the second rotating shaft 21 are connected by a universal joint. The shaft 13 is connected, so that the first and second shafts 11, 21 can rotate synchronously, and the second shaft 21 can swing in any direction relative to the first shaft 11, and the length of the first shaft 11 is greater than that...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com