Yarn nozzle of knitting horizontal machine

A technology of flat knitting machine and yarn feeder, which is applied in knitting, weft knitting, textiles and papermaking, etc. It can solve problems such as thread breakage and affecting the quality of knitwear, so as to ensure the quality of knitting, facilitate quick replacement, and facilitate installation and disassembly. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

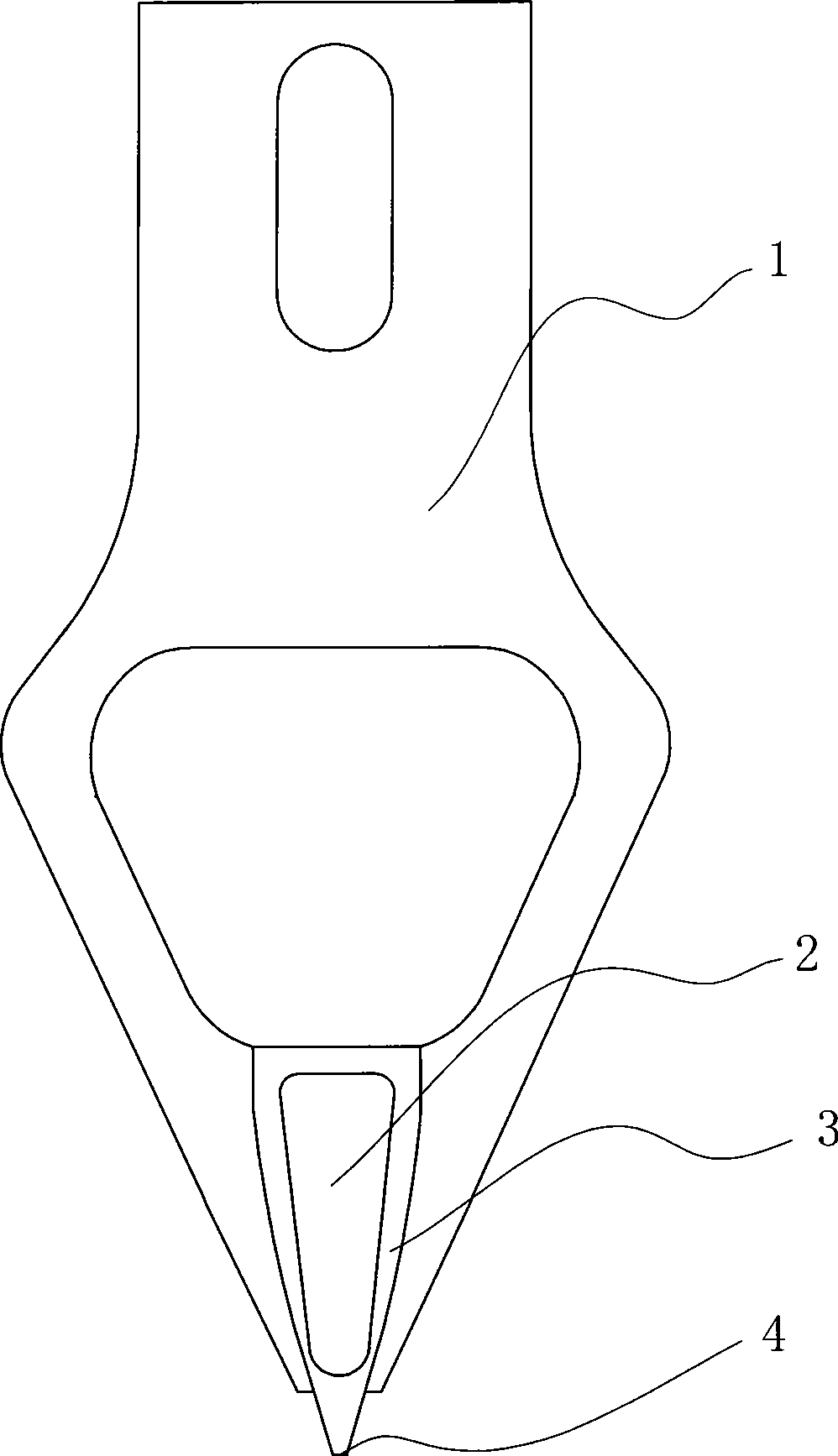

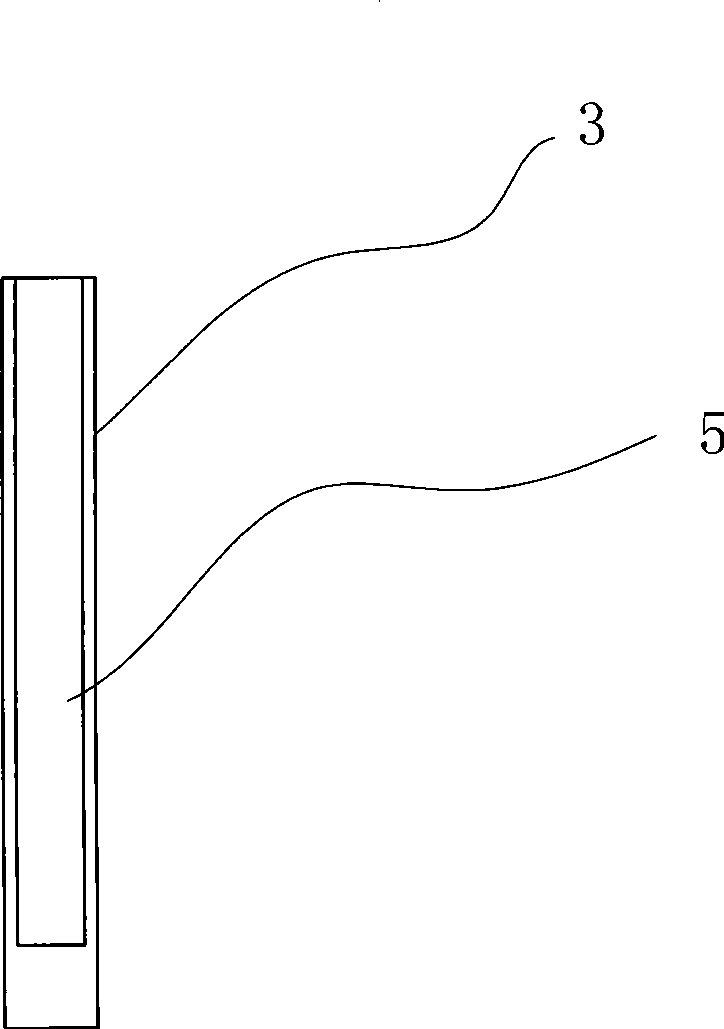

[0009] refer to figure 1 - figure 2 The yarn feeder of this flat knitting machine includes a fixed rod body 1 and a yarn delivery member 3, the yarn delivery member 3 is fixed on the fixed rod body 1, and a yarn delivery hole 4 is arranged on the yarn delivery member 3, and the yarn delivery hole 4 is arranged on the yarn delivery member 3. The entrance of the yarn feeding hole 4 of the yarn feeding part 3 is a hollow notch 2, the hollowed notch 2 allows the yarn to drop directly from the notch 2 after the yarn passes through the yarn feeding hole 4, and will not be blocked in the feeding hole 4. on the yarn hole 4, so the yarn feeder of this structure can ensure the normal yarn guide without thread breakage, thereby ensuring the knitting quality of the knitwear; , the chute 5 is matched with the fixed rod body 1, and the yarn delivery part 3 is inserted on the fixed rod body 1 through the chute 5. This installation method is very easy to disassemble, and the yarn delivery ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com