Flat knitting machine yarn carrier

A technology of flat knitting machines and yarn guides, which is applied in knitting, weft knitting, textiles and papermaking, etc. It can solve the problems of inaccurate and troublesome yarn feeding, and inaccurate yarn feeding of the yarn feeder of the yarn guide, and achieve yarn feeding Accurate in place, guarantee the effect of knitting quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

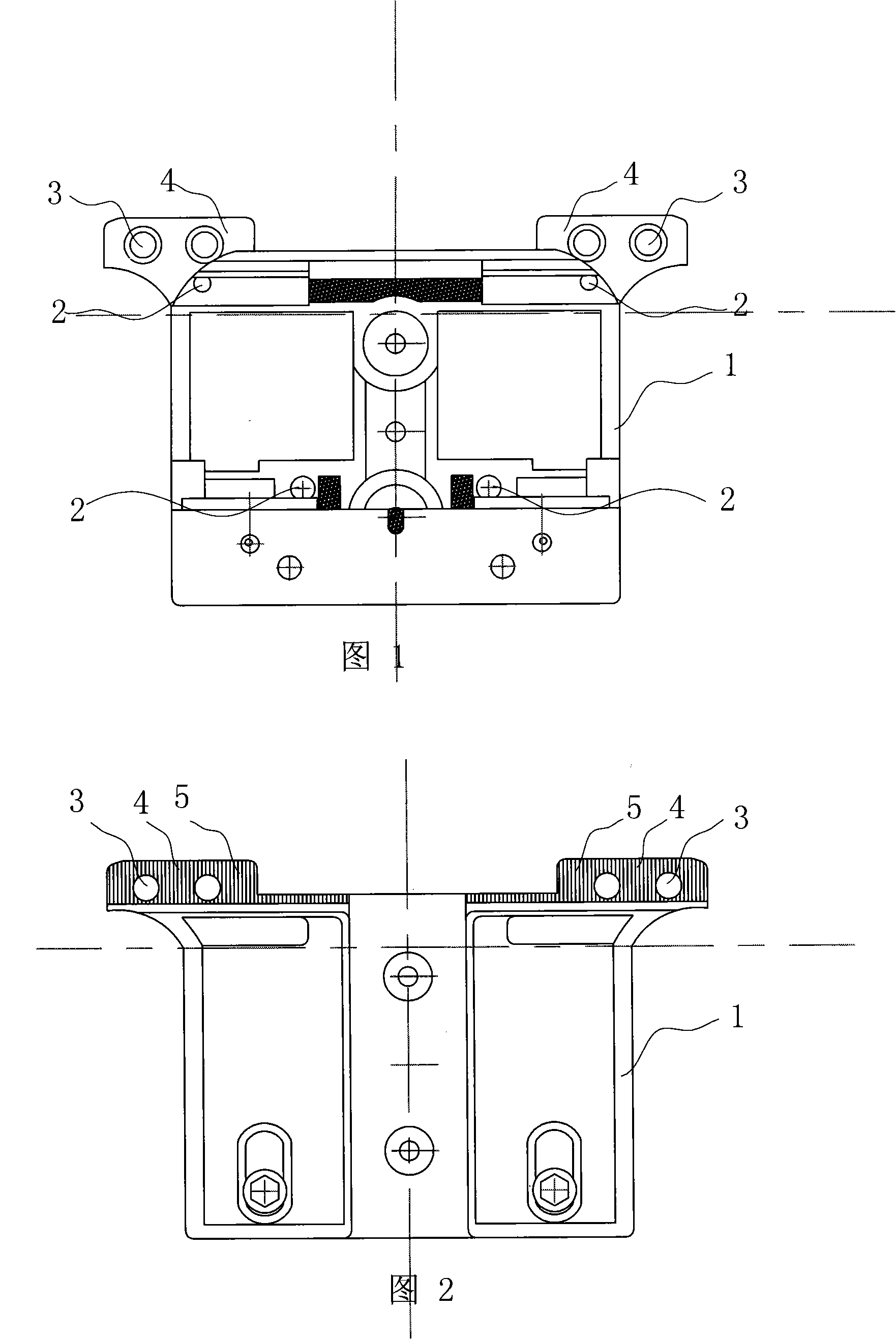

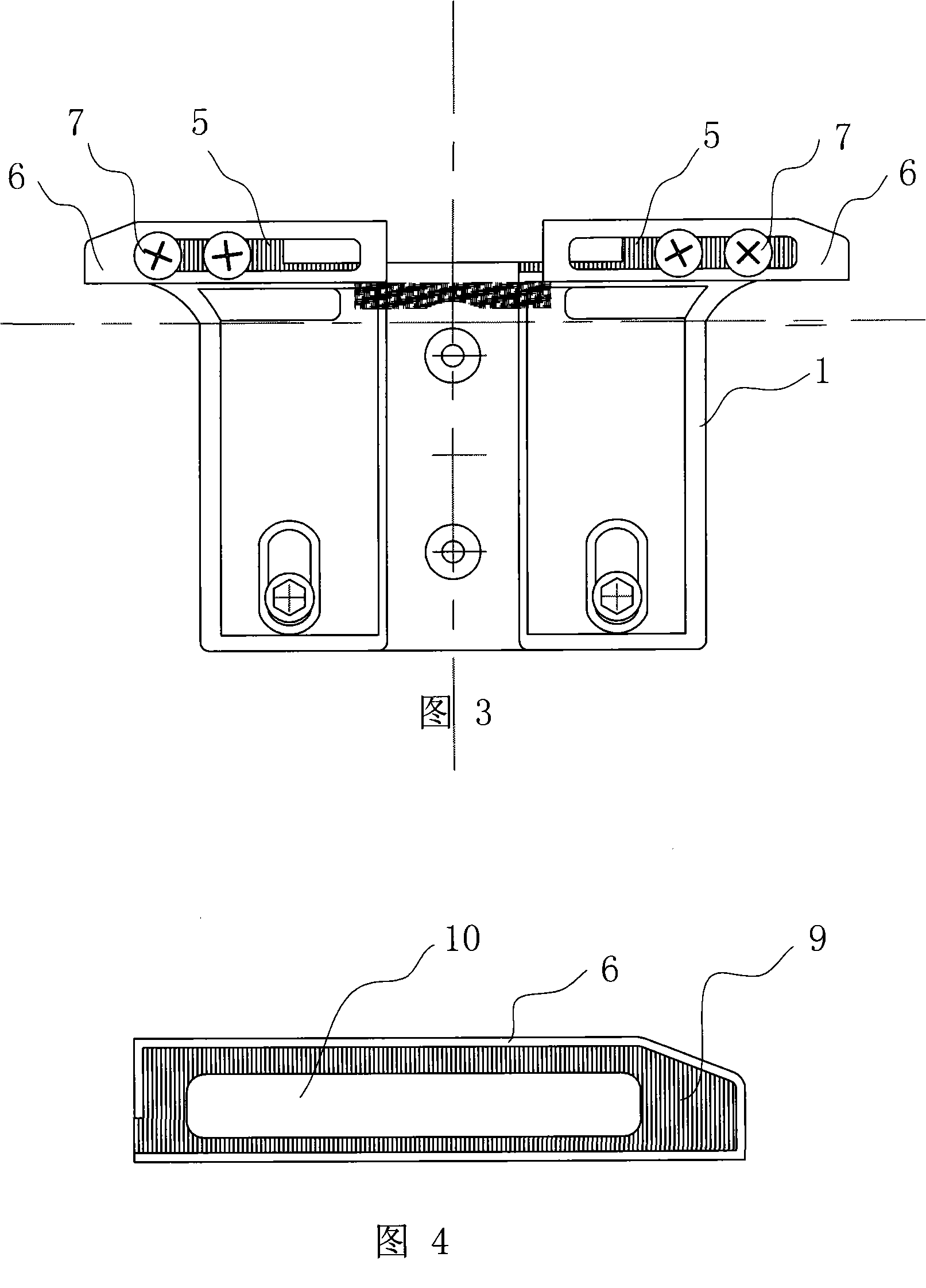

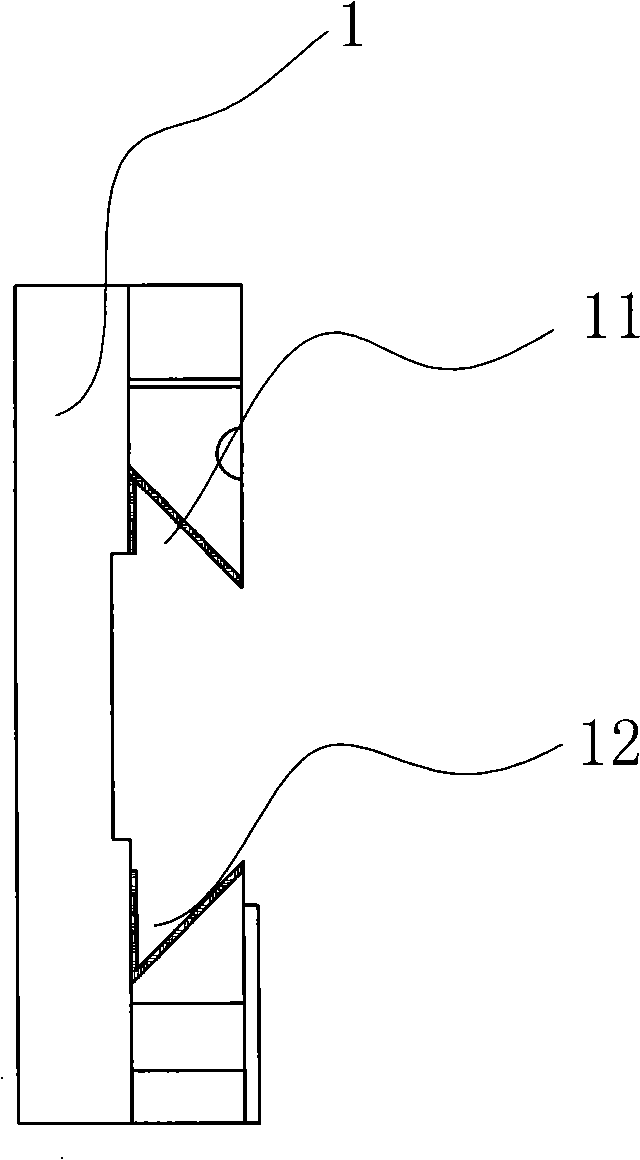

[0017] Referring to accompanying drawings 1-5, this knitting machine yarn guide has a main body 1 and left and right retaining arms 6, and a first angular groove 11 and a second angular groove 12 are arranged on the main body 1, and the second angular groove 12 is connected with the The first angle groove 11 is corresponding, and the first angle groove 11 and the second angle groove 12 are matched with the guide rail of the computerized flat knitting machine, so this yarn guide is exactly buckled in the horizontal through the first angle groove 11 and the second angle groove 12. On the guide rail of the machine, the left and right blocking arms 6 are adjustable and installed on the body 1; specifically, the left and right blocking arms 6 of the first embodiment are installed on the body 1 in this way: on the body 1 is provided with left and right retaining arm seat 4, and left and right retaining arm seat 4 is provided with screw hole 3, and described left and right retaining a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com