Squitter pulse welding method

A pulse welding and post-welding technology, used in welding equipment, arc welding equipment, manufacturing tools, etc., can solve the problems of burn-through of base metal and increase of line energy, and achieve the effect of improving appearance and suppressing line energy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

[0126] Hereinafter, embodiments of the invention will be described based on examples with reference to the drawings.

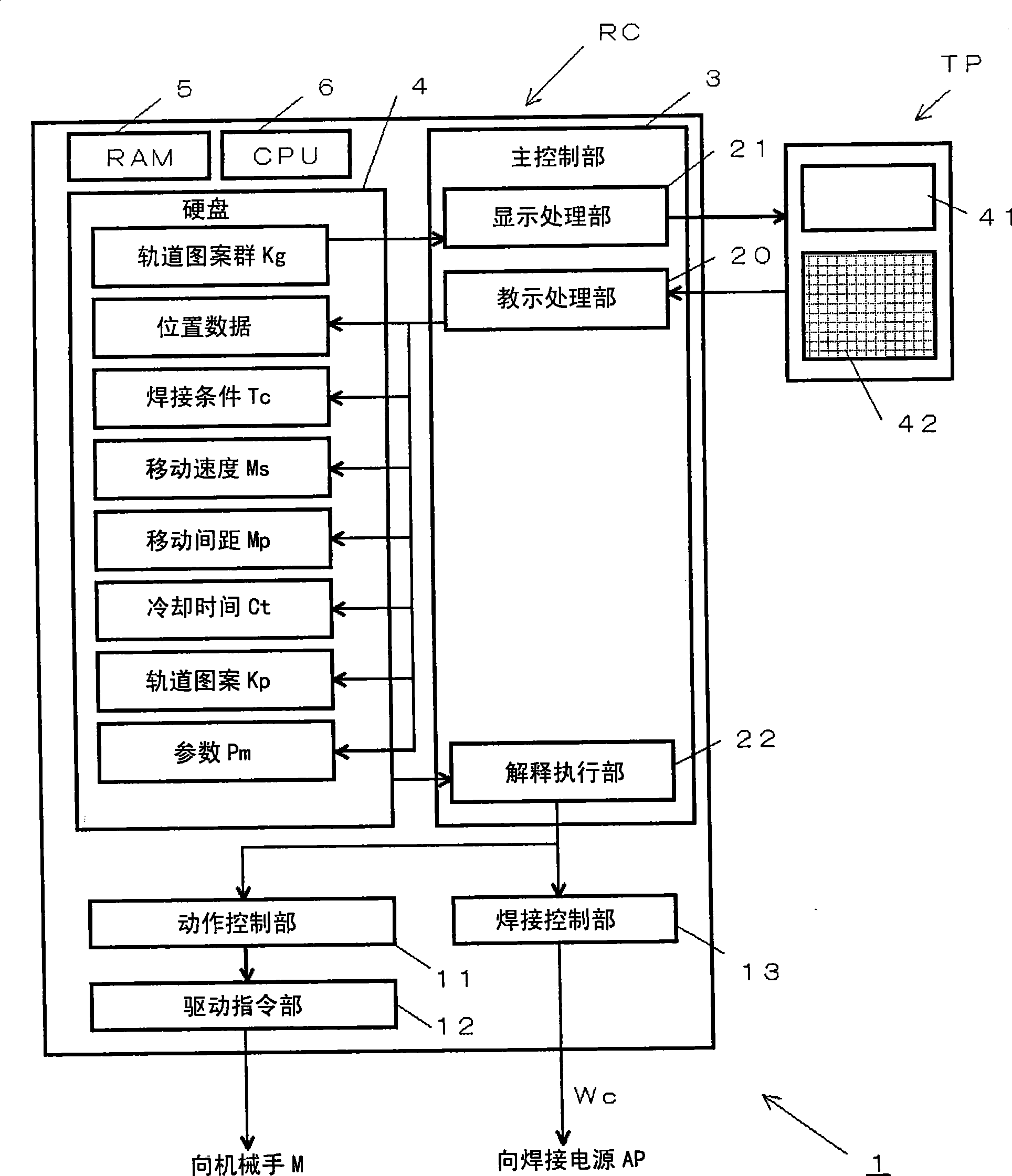

[0127] figure 1 It is a block diagram of the intermittent pulse welding device 1 to which the intermittent pulse welding method according to the present invention is applied. In this figure, with the prior art Figure 13 The difference lies in the robot controller RC and the teaching operation panel TP as the operating unit. The other manipulator M, welding power source AP, wire spool 56, gas tank 58, etc., which have been described in the prior art, are not shown and omitted. Hereinafter, the robot controller RC and the teaching operation panel TP constituting the main parts of the present invention will be described.

[0128] The robot control device RC is used to control the welding operation of the manipulator M, and is provided with: a main control unit 3 serving as a central pivot, an operation control unit that performs orbit calculations of the manipulat...

Embodiment approach 2

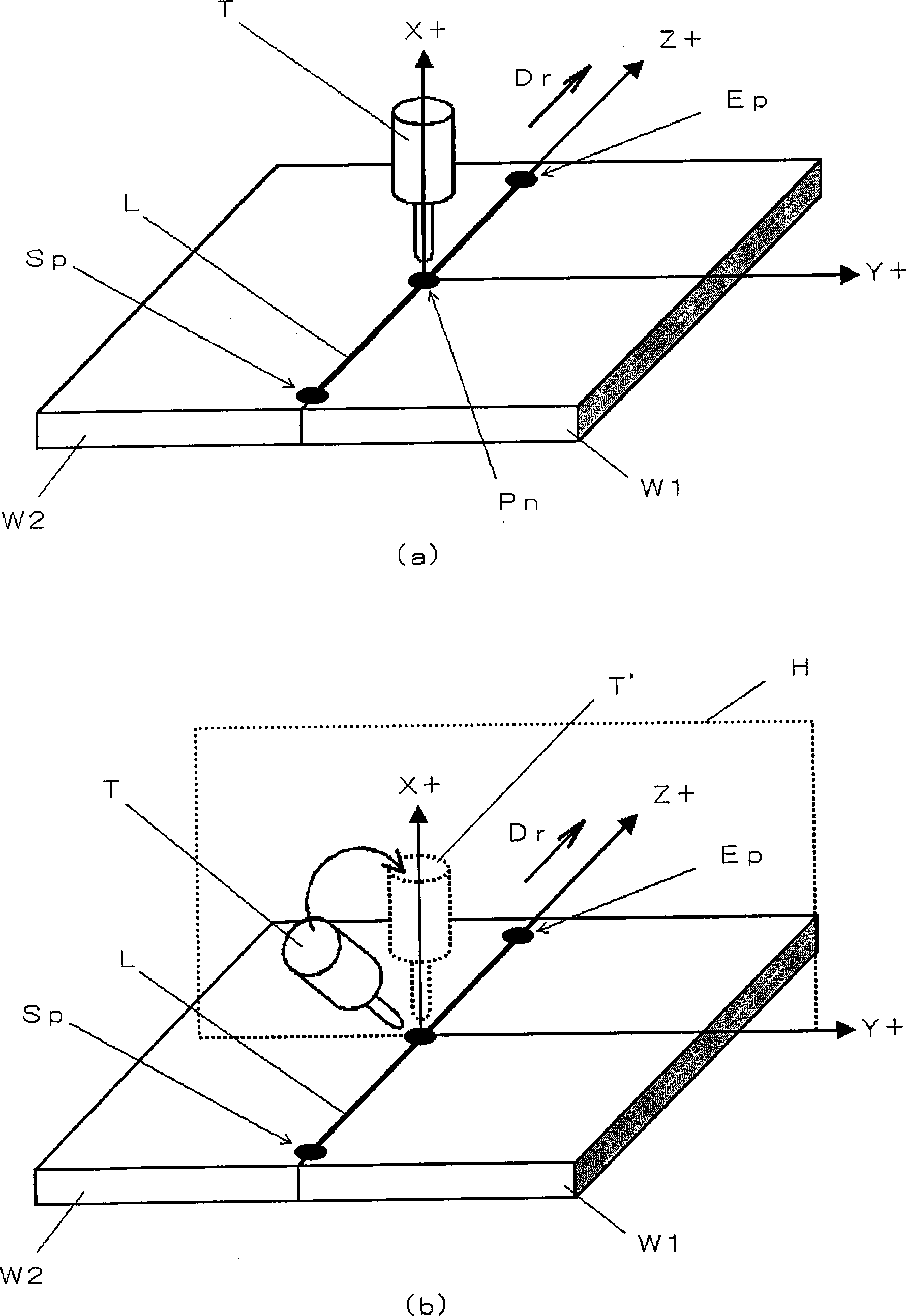

[0160] Next, the second embodiment of the present invention will be described. In the first embodiment, the welding track is generated on the work line direction side of the work position Pn, but in the second embodiment, the welding track is generated around the work position Pn.

[0161] Figure 6 This is a diagram showing how a circular welding track is generated around the work position Pn in the second embodiment. In this figure, and Figure 4 The difference is that the working position Pn is used as the center position Cc' of the circular welding track Kc'. Others are the same as the first embodiment, so the description is omitted.

[0162] The circular welding track Kc' is generated as follows. First, using the work position Pn as the center position Cc', a circular orbit having a circle radius value Cr in the YZ plane is calculated. After that, on the circular orbit, the welding start and end position Wp' is calculated at a position away from the circle radius value Cr fr...

Embodiment approach 3

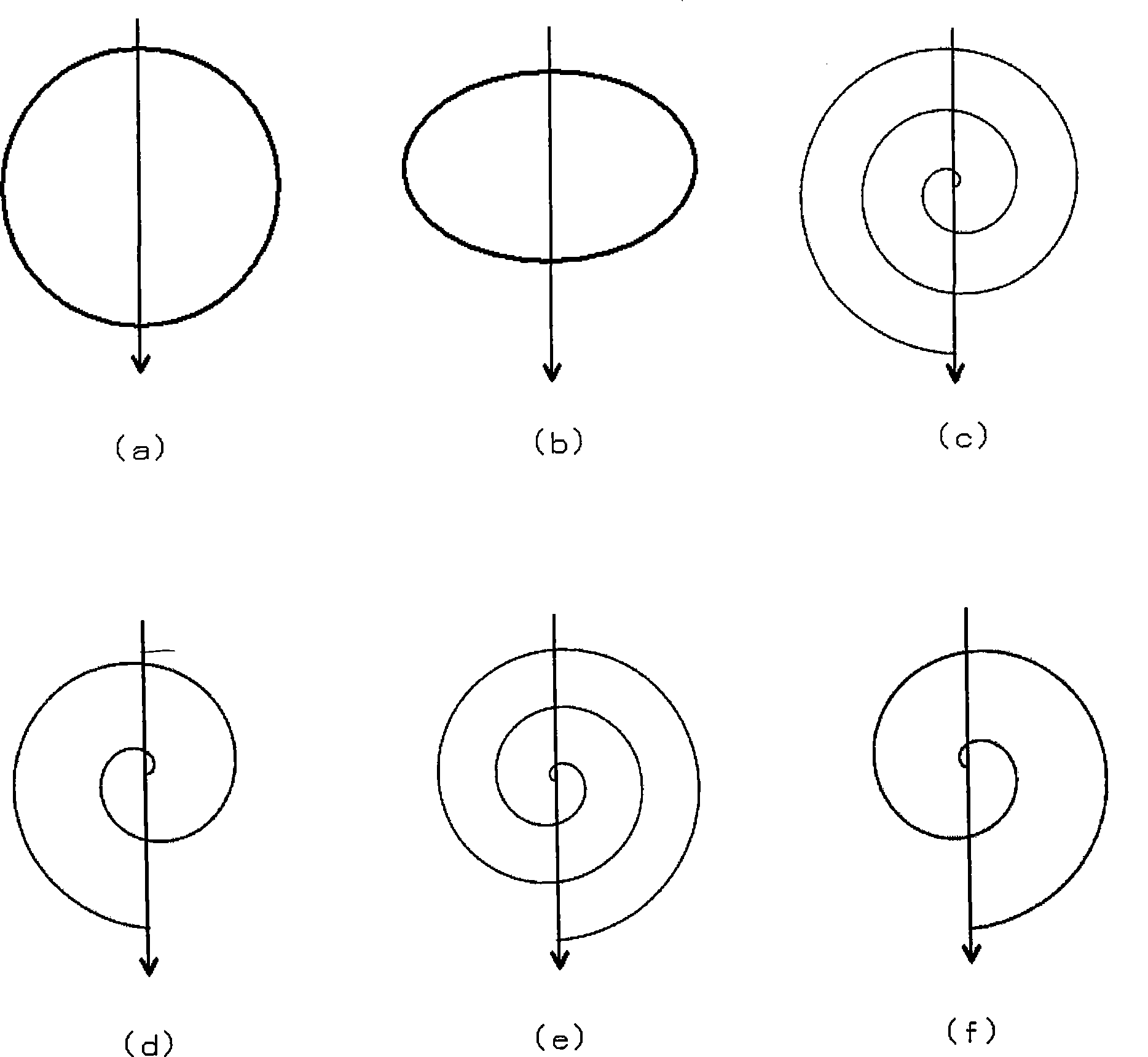

[0178] Next, the third embodiment of the present invention will be described. In the first and second embodiments, the circular welding track Kc (Kc') or the elliptical welding track Kd (Kd') is generated on the work line direction side of the work position Pn or around the work position Pn. However, in the third embodiment, the following The working position Pn is a spiral welding track that spirally rotates toward the outside.

[0179] Picture 9 This is a diagram used to illustrate the spiral welding track. This figure is a view of the YZ plane of the welding line coordinate system described in Embodiment 1 viewed from the X+ direction, and shows how the spiral welding track Kr is drawn on the YZ plane. In this figure, the working position Pn, the working line L, the working line direction Dr, and the rotation direction Rd are related to Figure 4 The parts assigned with the same symbols are the same, so the description is omitted.

[0180] The spiral welding track Kr shown in...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap