Method for manufacturing yarn barrel and yarn processor

A technology of yarn manufacturing and manufacturing method, applied in the field of yarn processing machines, can solve problems such as being unsuitable for fancy yarn dyeing, and achieve the effect of small equipment cost and elimination of rewinding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

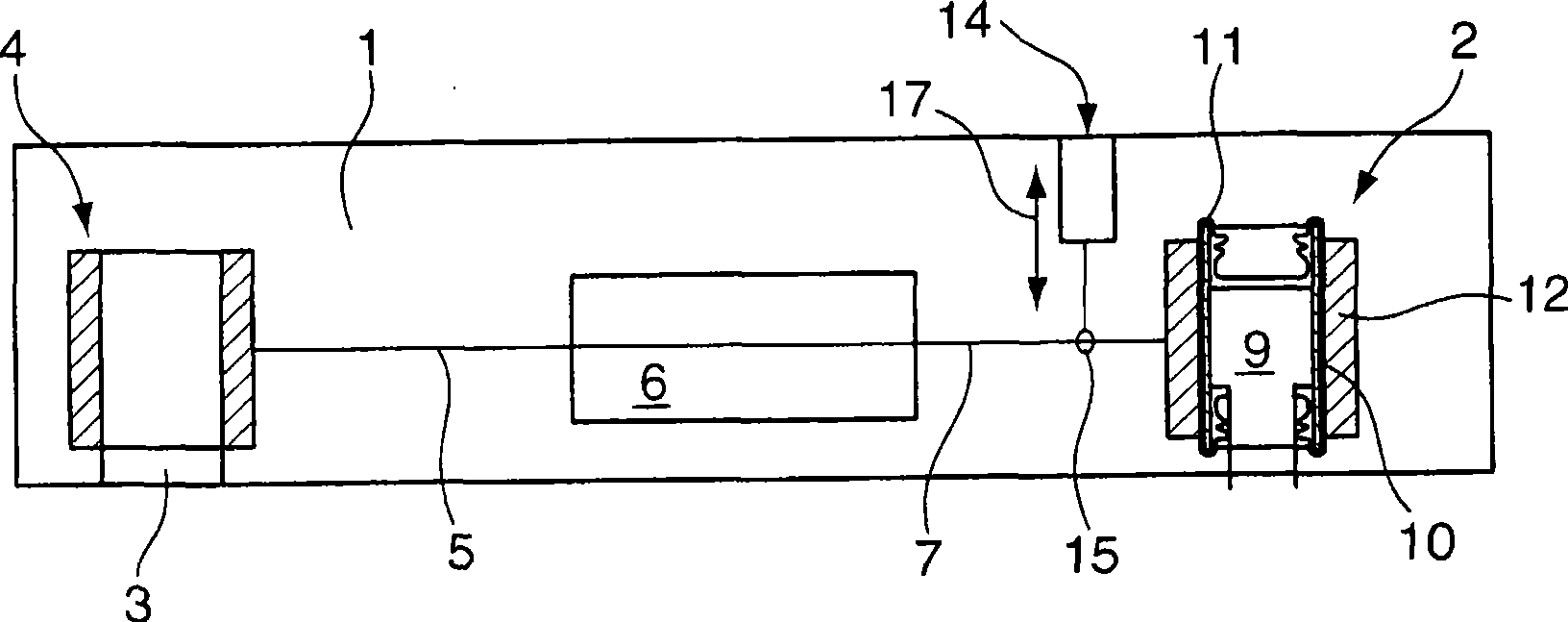

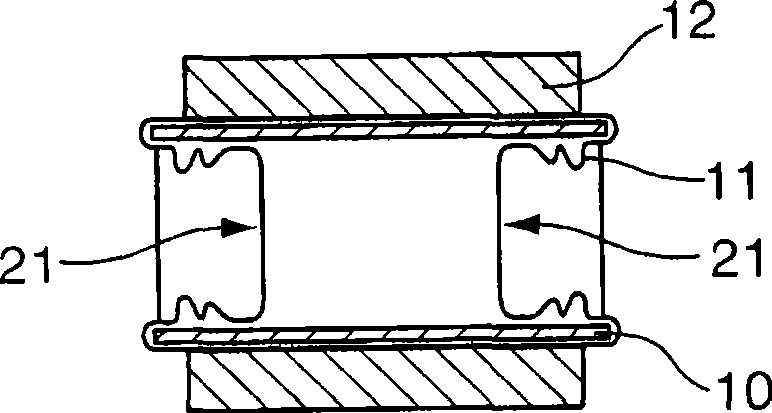

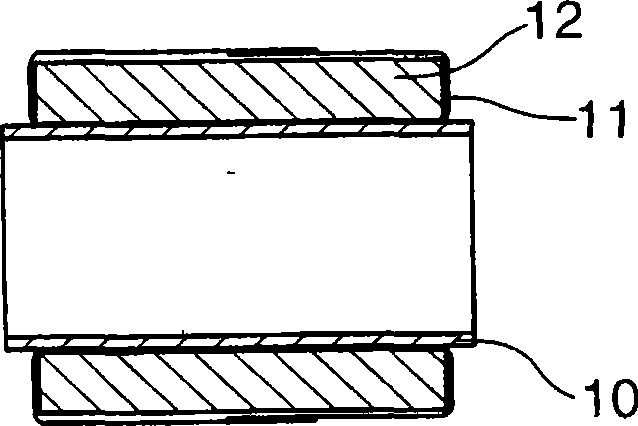

[0035] figure 1 A schematic diagram of a yarn processing machine 1 according to the invention is shown. The yarn processing machine 1 is used for carrying out the method according to the invention for the production of yarn bobbins, ie for the production of dyeing bobbins with cross-winding as twisted yarn bobbins 2 . The filament yarn 5 is processed in a yarn processing unit 6 , for example in a false twist texturing unit, from a yarn supply bobbin 4 prepared on the yarn supply bobbin creel 3 into a fancy yarn 7 . The fancy yarn 7 is wound directly onto a dyeing bobbin with cross-winding as a twisting bobbin 2 on the same yarn processing machine 1, wherein the twisting bobbin 2 is supported on the yarn processing machine 1, wherein the rotation of the twisting bobbin 2 for winding the fancy yarn 7 is preferably directly driven via a motor not shown. The twisting creel 9 thus has a single spindle drive. Wind an armhole package as a dyeing bobbin. For this, a bobbin 10 is s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com