Design of universal hydraulic coupling

A technology of hydraulic pipe joints and joints, applied in the direction of pipes/pipe joints/fittings, adjustable connections, mechanical equipment, etc., to achieve the effect of avoiding too small bending radius, low cost, and optimizing the direction of metal pipes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

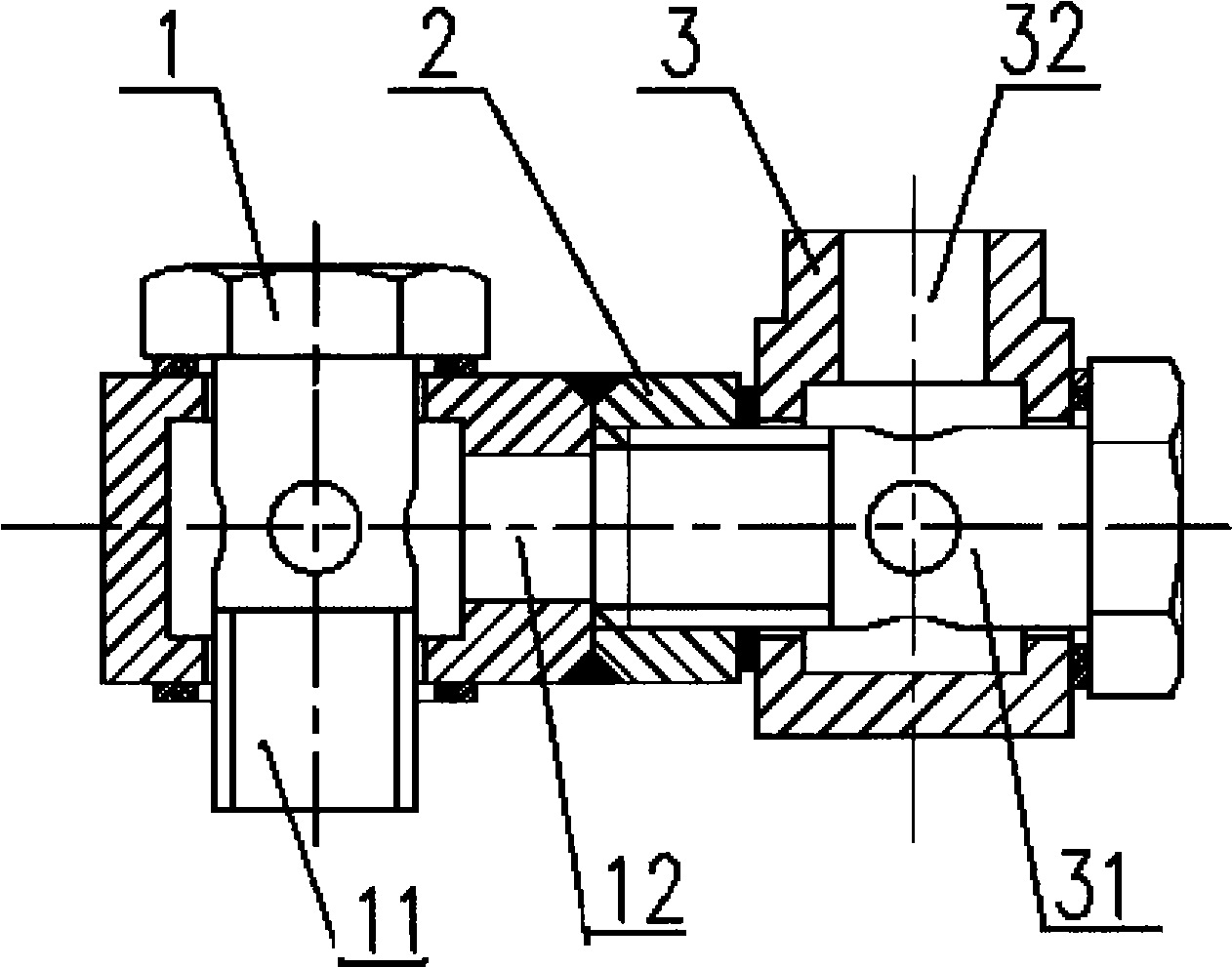

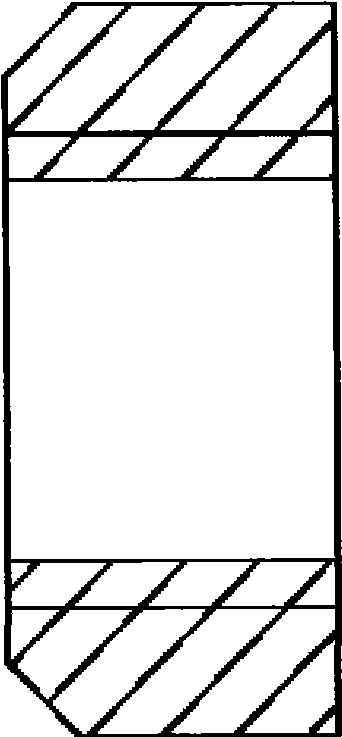

[0013] like figure 1 As shown, the embodiment of the present invention consists of a welded hinged pipe joint 1 , a transition joint 2 , and a welded hinged pipe joint 2 3 . The welded articulated pipe joint 1 has an axial oil port 11 and a radial oil port 12, and the radial oil port 12 is welded with the transition joint 2. The structure of transition joint 2 is as follows figure 2 As shown, there is a straight threaded hole, both ends are flat, and one end is chamfered to facilitate welding. The welded joint 2 3 has an axial oil port 31 and a radial oil port 32 , and the axial oil port 31 is connected with the transition joint 2 . Since both welded articulated pipe joints can rotate freely around themselves 360 degrees, and the rotary motion of welded articulated pipe joint two is always perpendicular to the rotary motion of welded articulated pipe joint one, the two vertical rotary motions can make the oil port 11 and the oil port 32 have any spatial angle, that is to s...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap