Conveying apparatus using slide loading platform

A technology of handling device and carrier, which is used in transportation, packaging, motor vehicles, etc., to achieve the effect of good straightness and inhibition of wear and tear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

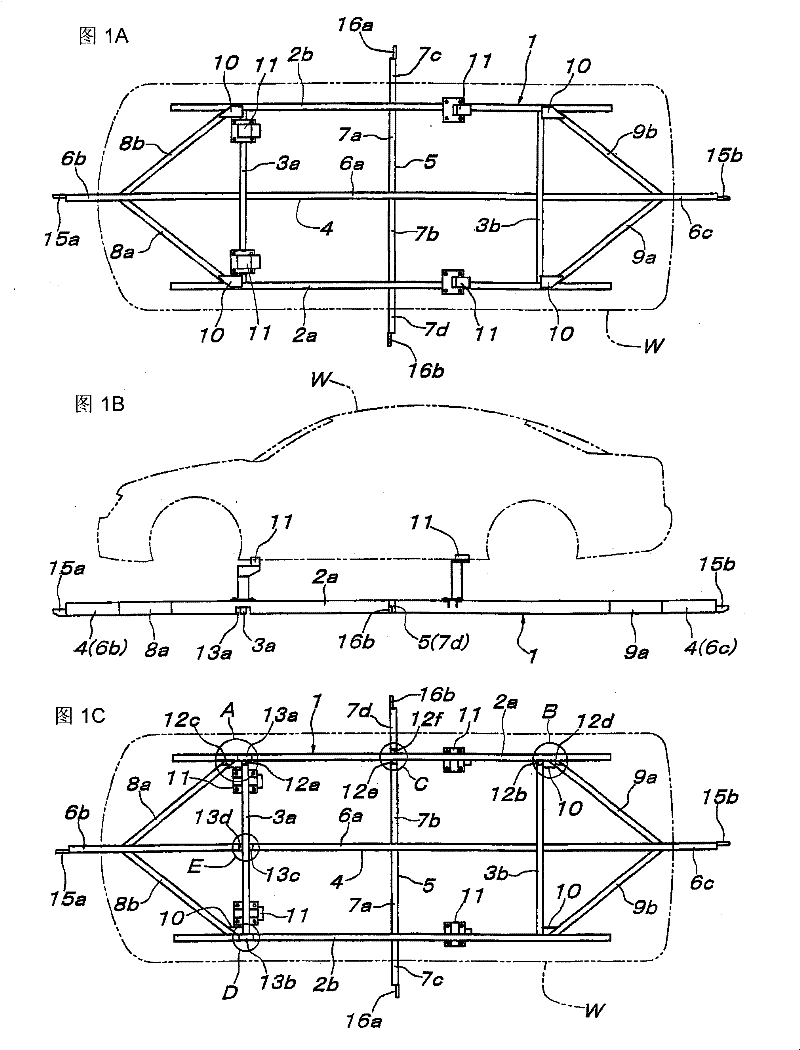

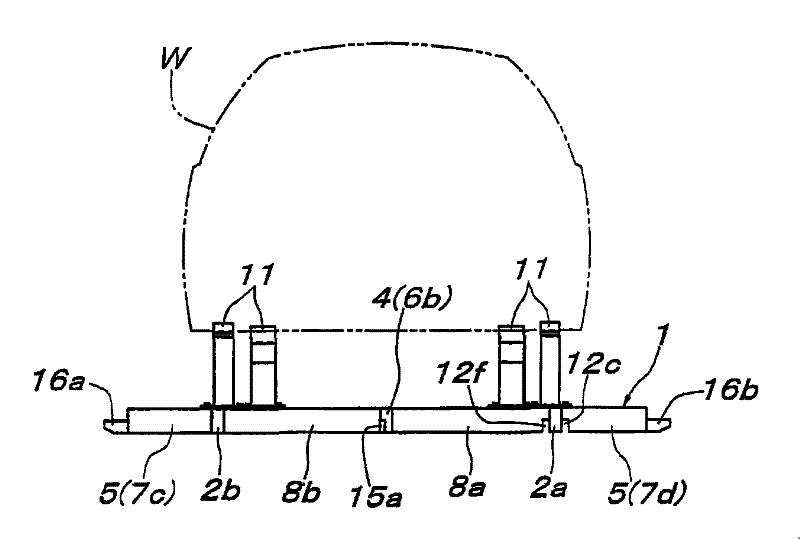

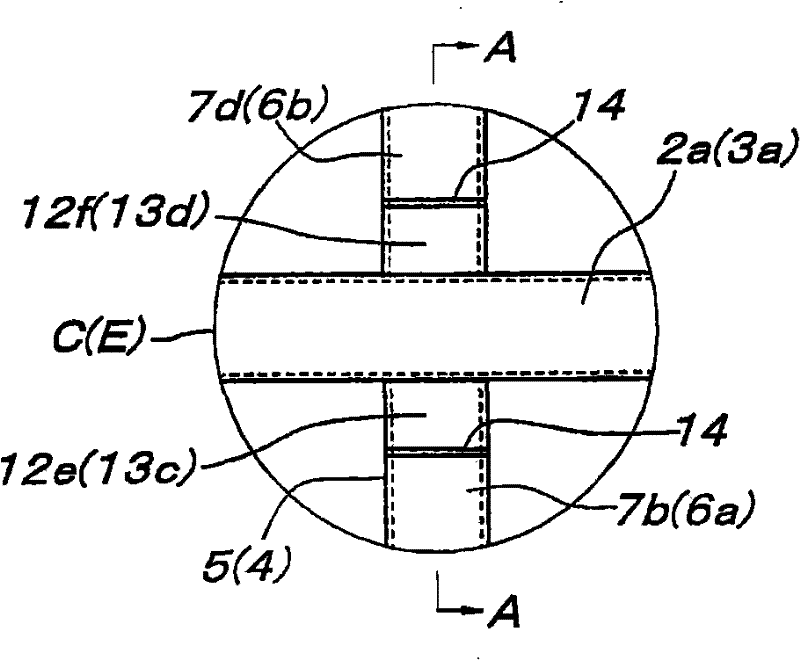

[0079] Although the specific embodiments of the present invention are described below according to the accompanying drawings, in Fig. 1A, Fig. 1B, Fig. 1C and figure 2 Among them, 1 is a slide stage for supporting and conveying a workpiece (automobile body) W, including a pair of left and right long bar-shaped sliding members 2a, 2b parallel to the longitudinal direction of the supported workpiece W, and A pair of front and rear parallel short rod-shaped sliding members 3a, 3b are arranged at the center between the long rod-shaped sliding members 2a, 2b parallel to the longitudinal direction of the workpiece W to be supported, and are longer than the entire length of the workpiece W to be supported. A long friction drive rod 4 for vertical feeding and a short bar-shaped sliding member 3a, 3b arranged in the center between the supported workpiece W in the width direction and longer than the width of the supported workpiece W are provided. A cross feeds rod 4 with friction drive...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com