Automatic separation method and apparatus for metallic rod

A metal bar, automatic separation technology, applied in the direction of automatic packaging control, packaging, packaging protection, etc., can solve the problem that the automatic separation of metal bars cannot be effectively solved, and achieve the effect of avoiding inaccurate quantity, simple operation and reducing waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

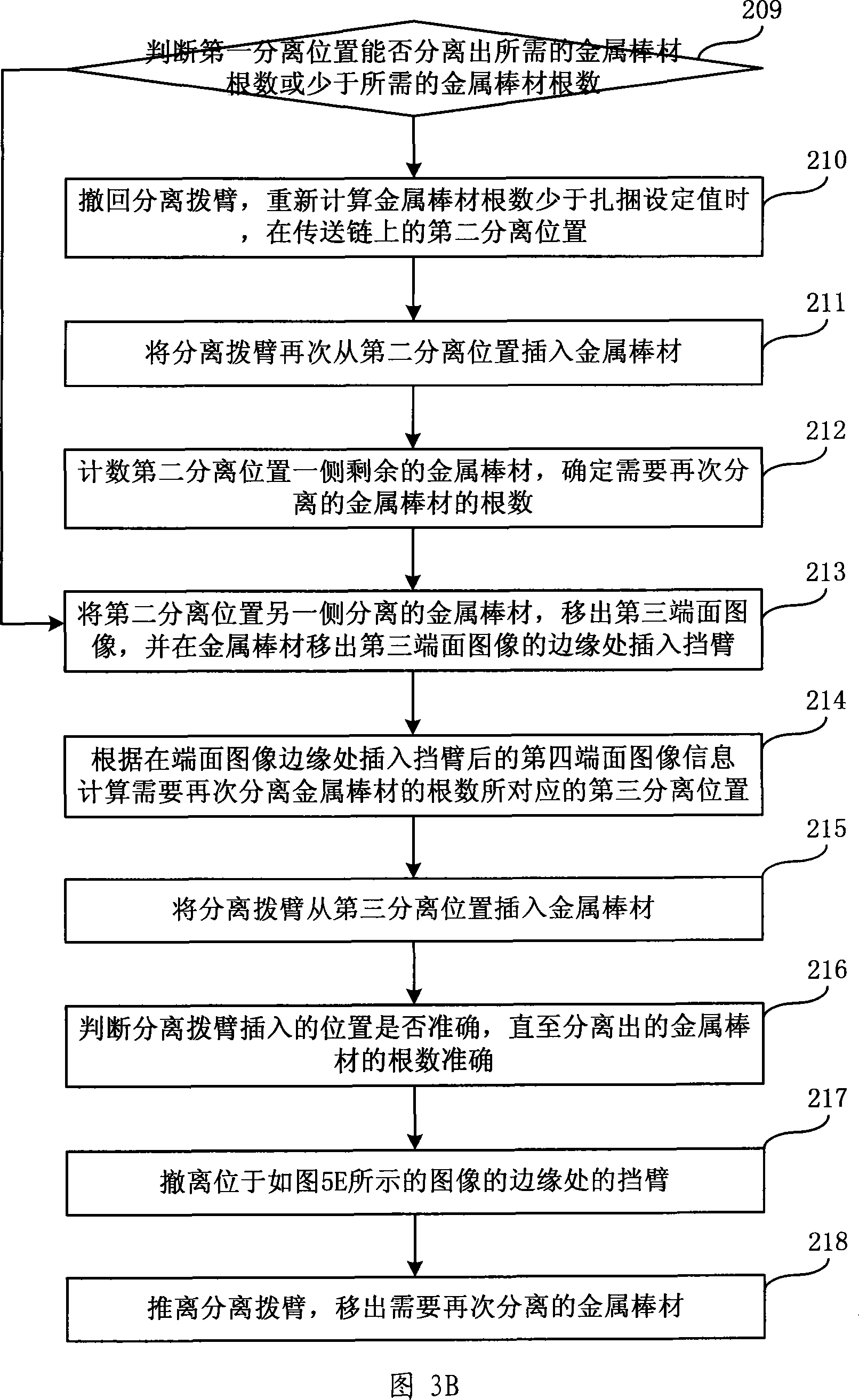

[0032] The metal bar automatic separation method and device of the present invention, through the identification and counting of the end face image of the metal bar, when the number of metal bars bound into bundles is reached, the number of metal bars on the conveyor chain is calculated according to the end face image When the set number of positions is reached, the separation arm or the combination of the separation arm and the stop arm is used to automatically separate the metal bar. It avoids the inaccurate quantity of bundled metal bars caused by uncertain factors when manually separating the metal bars, and can improve efficiency and reduce waste of human resources.

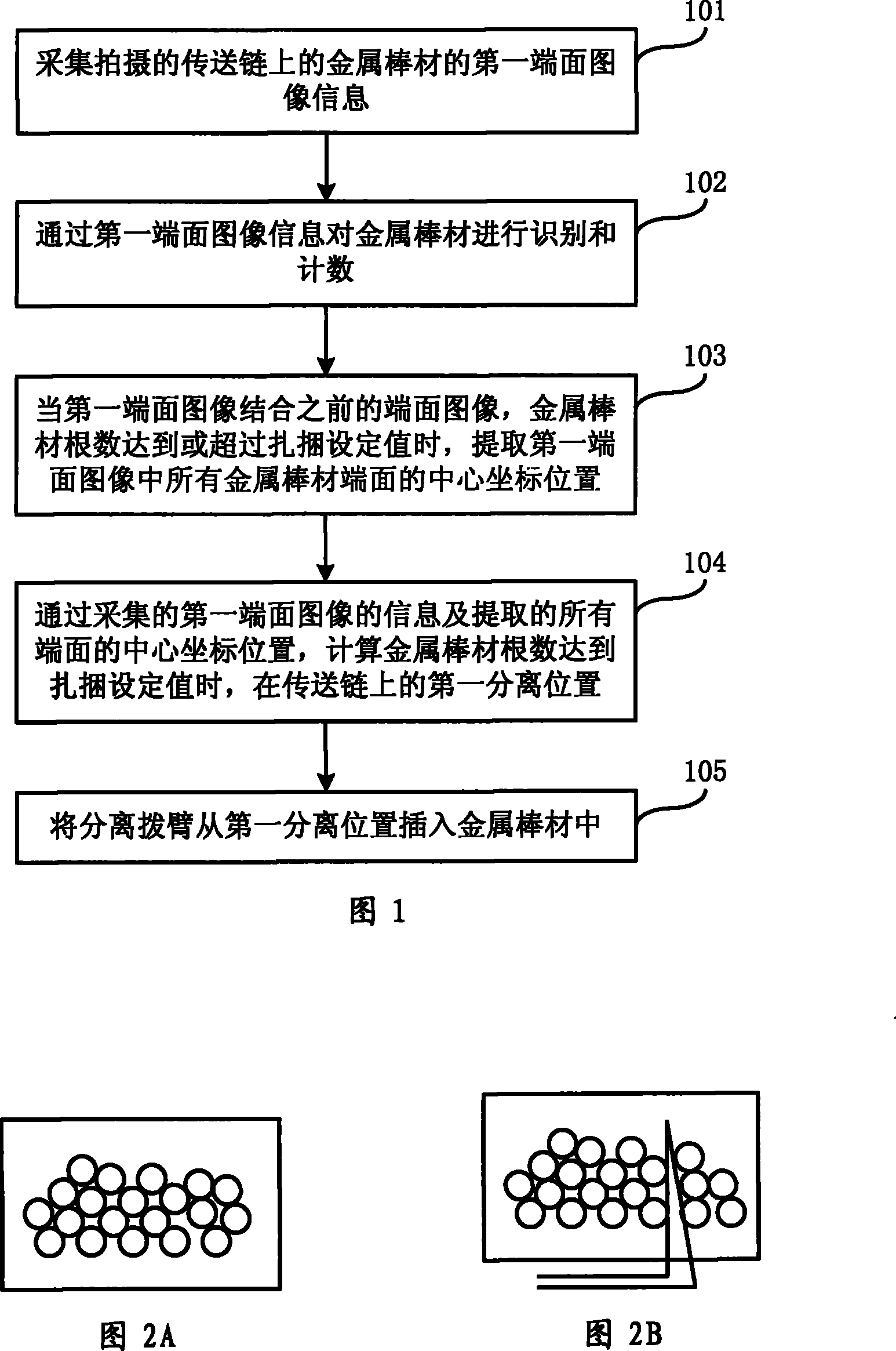

[0033] like figure 1 As shown, it is the method flow chart of Embodiment 1 of the metal rod automatic separation method of the present invention, and the specific steps are as follows:

[0034] The image acquisition of the metal bars conveyed on the conveyor chain is continuous, and the information of the m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com