Method for judging setting of draw-bead in part drawing and moulding

A technology for drawbeads and parts, which is applied in the field of drawbead setting and judgment, can solve the problems of time-consuming, etc., and achieve the effects of less calculation, elimination of wrinkling, and fewer steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be described in detail below in conjunction with the accompanying drawings.

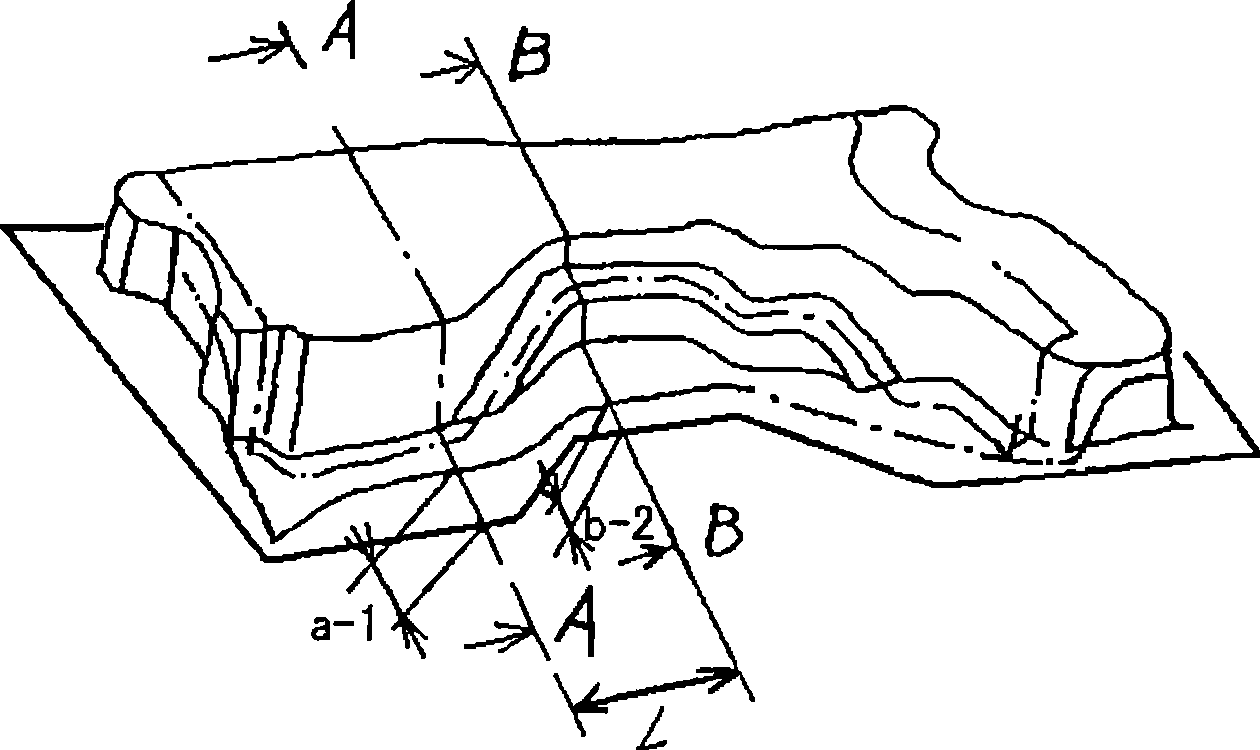

[0017] For such as figure 1 For the products shown or similar products, the cross-sections of some different positions are quite different, so there are different inflows. If there is no treatment, if the inflow difference is too large, the formed product will appear wrinkled. One of the processing methods is to set up drawbeads to artificially adjust the flow of materials through drawbeads, so that the difference in inflow at different sections becomes smaller and wrinkling is avoided. The present invention provides a kind of judging method for quickly determining the setting quantity of drawbeads, which comprises the following steps:

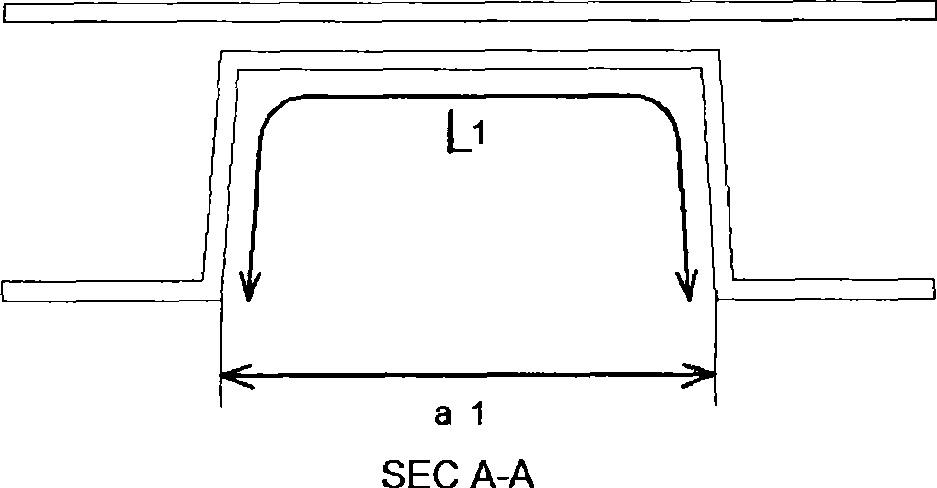

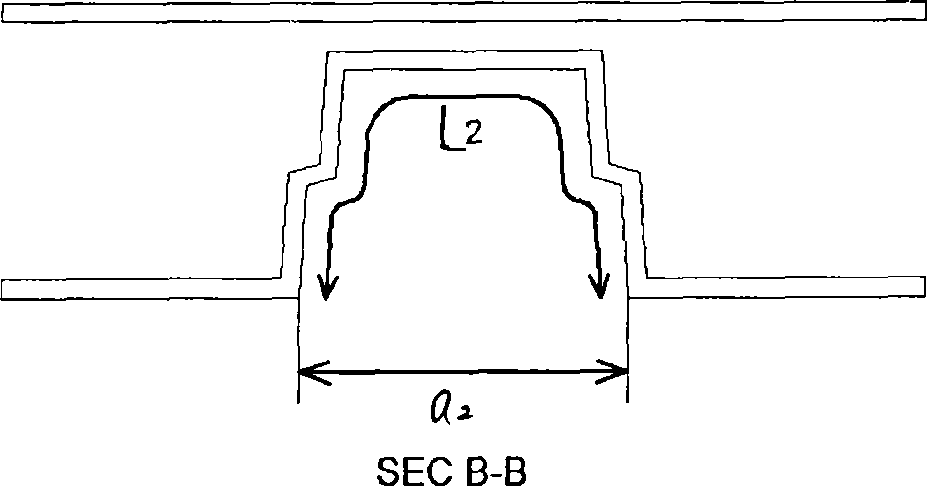

[0018] (1), first determine the two sections with large cross-section differences, and the distance between the two sections is L; the selection of the cross-section is determined based on experience, for example, in places where th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com