Operating mechanism for a printer cover, and a printer

A technology for opening and closing covers and printers, applied to printing devices, printing, connecting components, etc., to achieve the effect of stabilizing printing quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] Hereinafter, embodiments of an opening and closing cover structure of a printer to which the present invention is applied will be described with reference to the drawings.

[0039] (the whole frame)

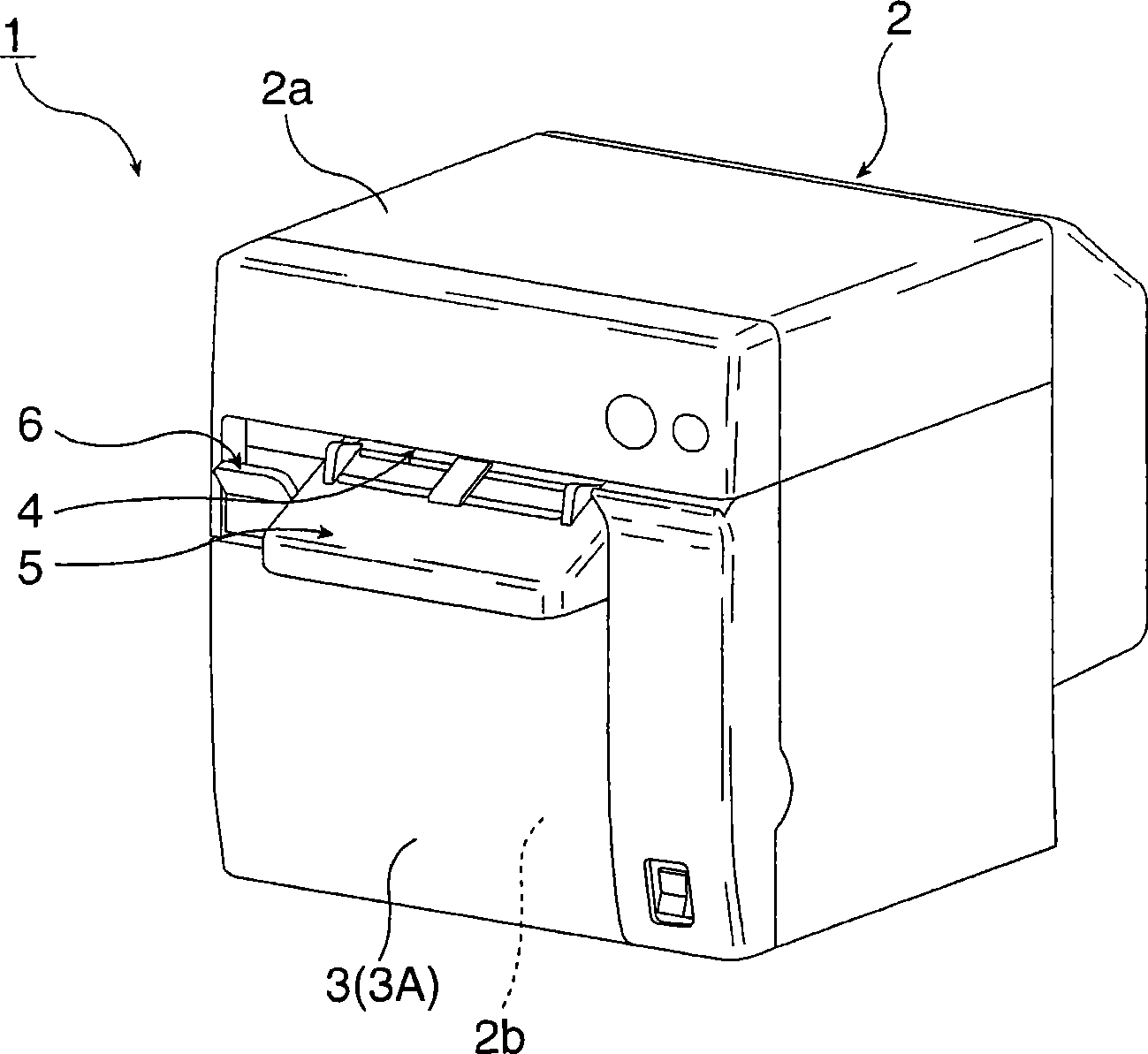

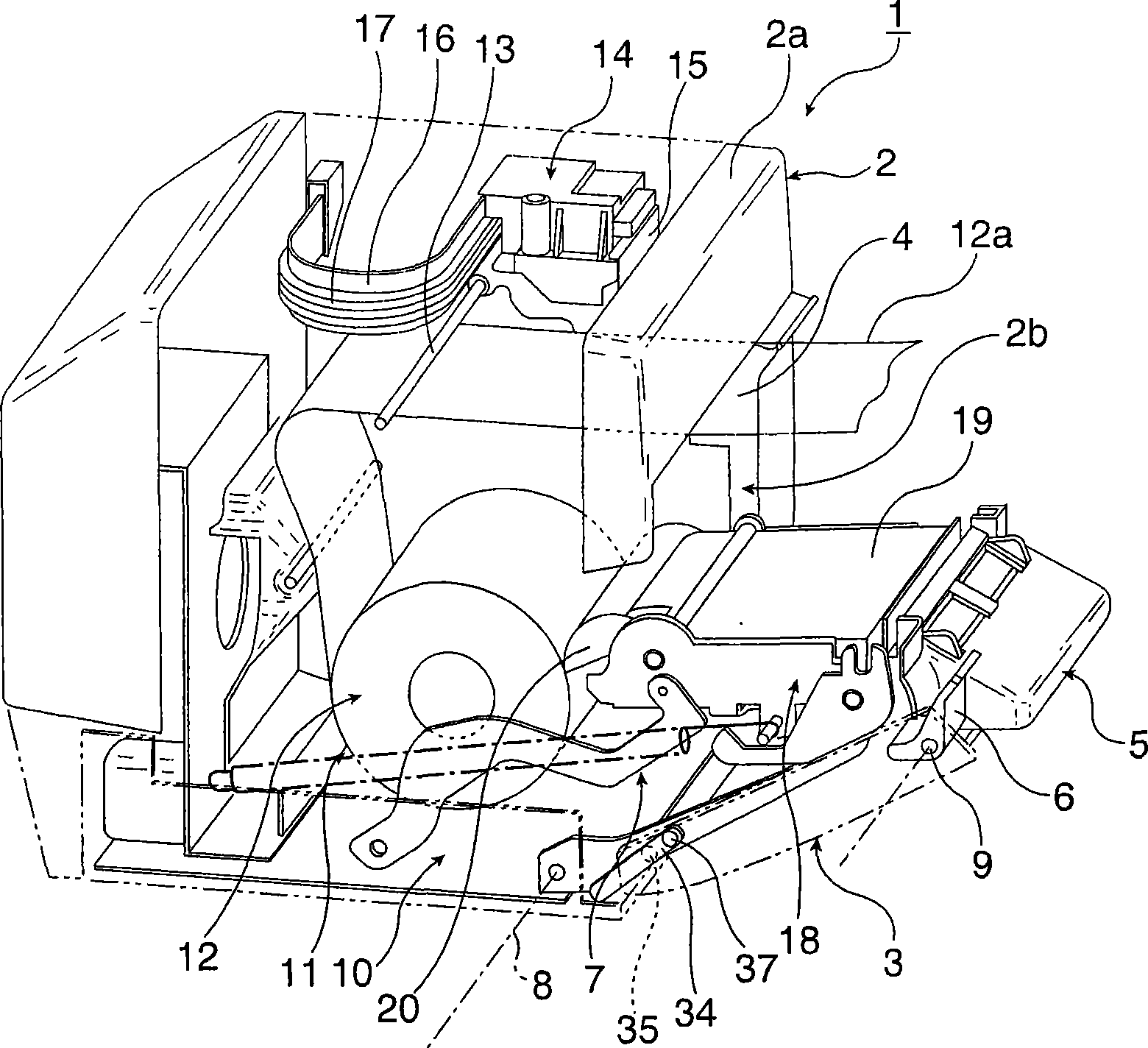

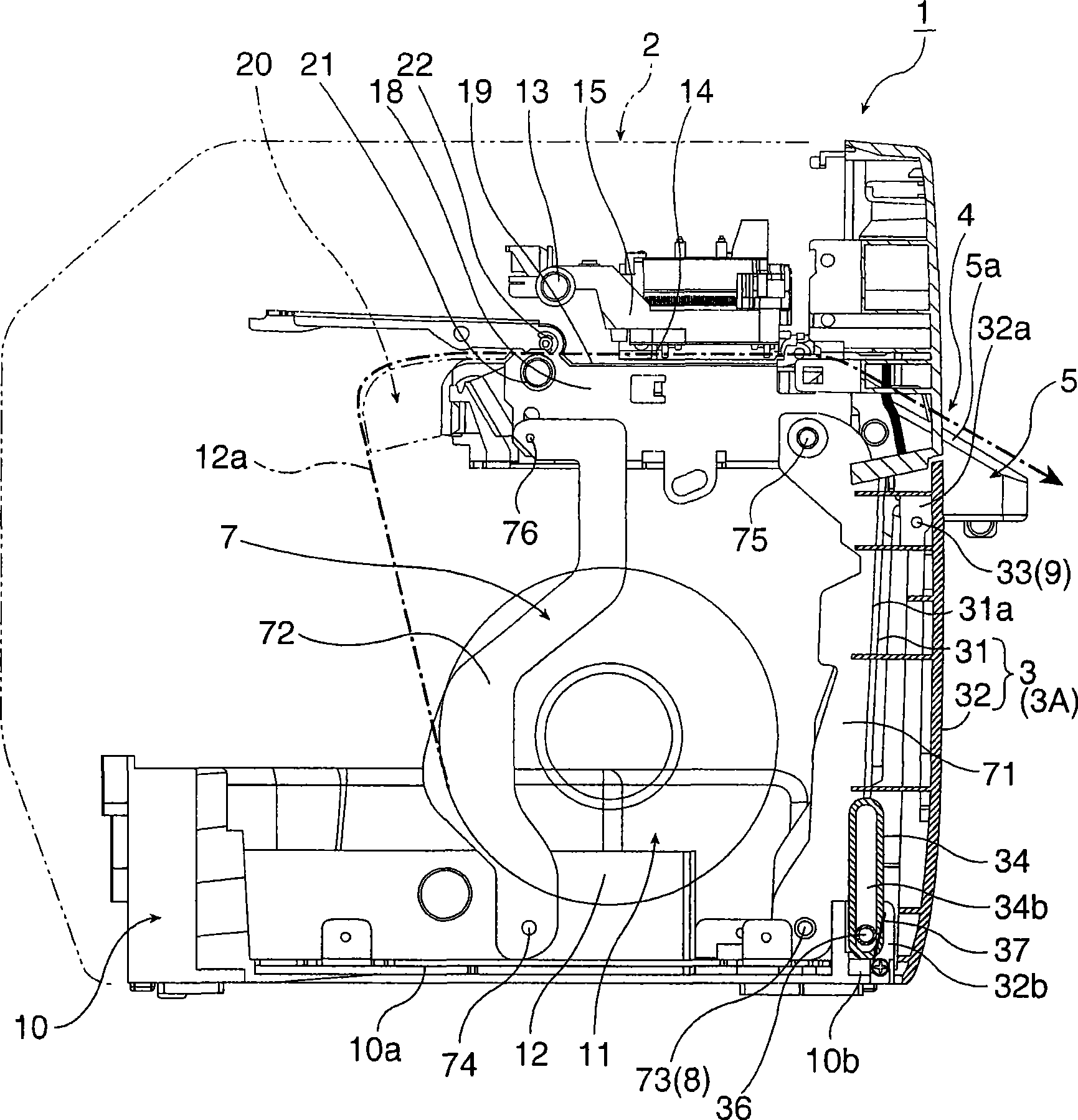

[0040] figure 1 is a perspective view showing the appearance of an inkjet roll paper printer according to this embodiment, figure 2 It is an explanatory diagram of main parts showing a state where the access cover of the roll paper printer is opened. The roll paper printer 1 has a printer 2 generally in the shape of a rectangular parallelepiped as a whole, and an access cover 3 attached to the front of the printer 2 . A recording paper discharge port 4 having a predetermined width is formed on the front surface of an exterior case 2 a of the printer 2 . A paper discharge guide 5 protrudes forward from the lower side of the recording paper discharge port 4 , and a cover opening and closing lever 6 is arranged on the side of the paper discharge guide 5 . On the lower si...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com