Contactor device

A contactor and terminal connection technology, applied in the direction of coupling devices, measuring devices, contact parts, etc., can solve problems such as difficulty in manufacturing contactors, contactor manufacturing errors, machine stop position errors, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

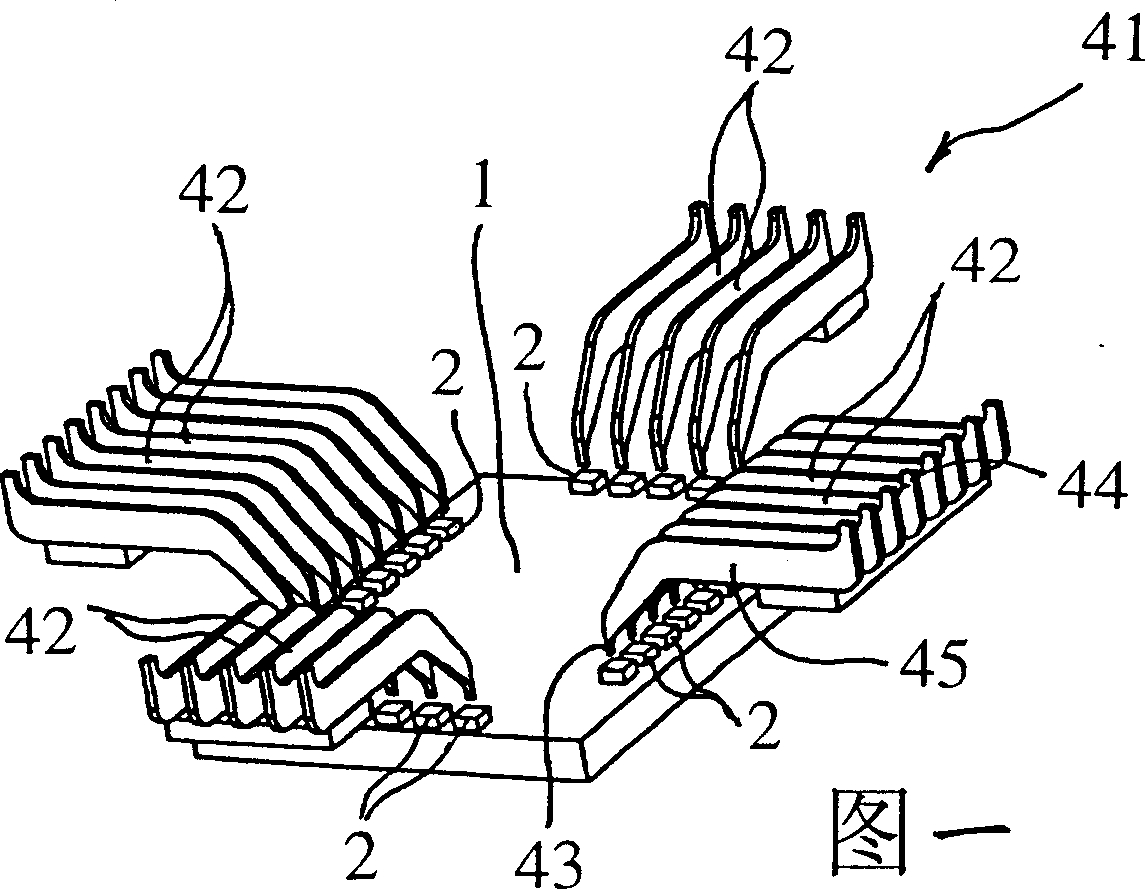

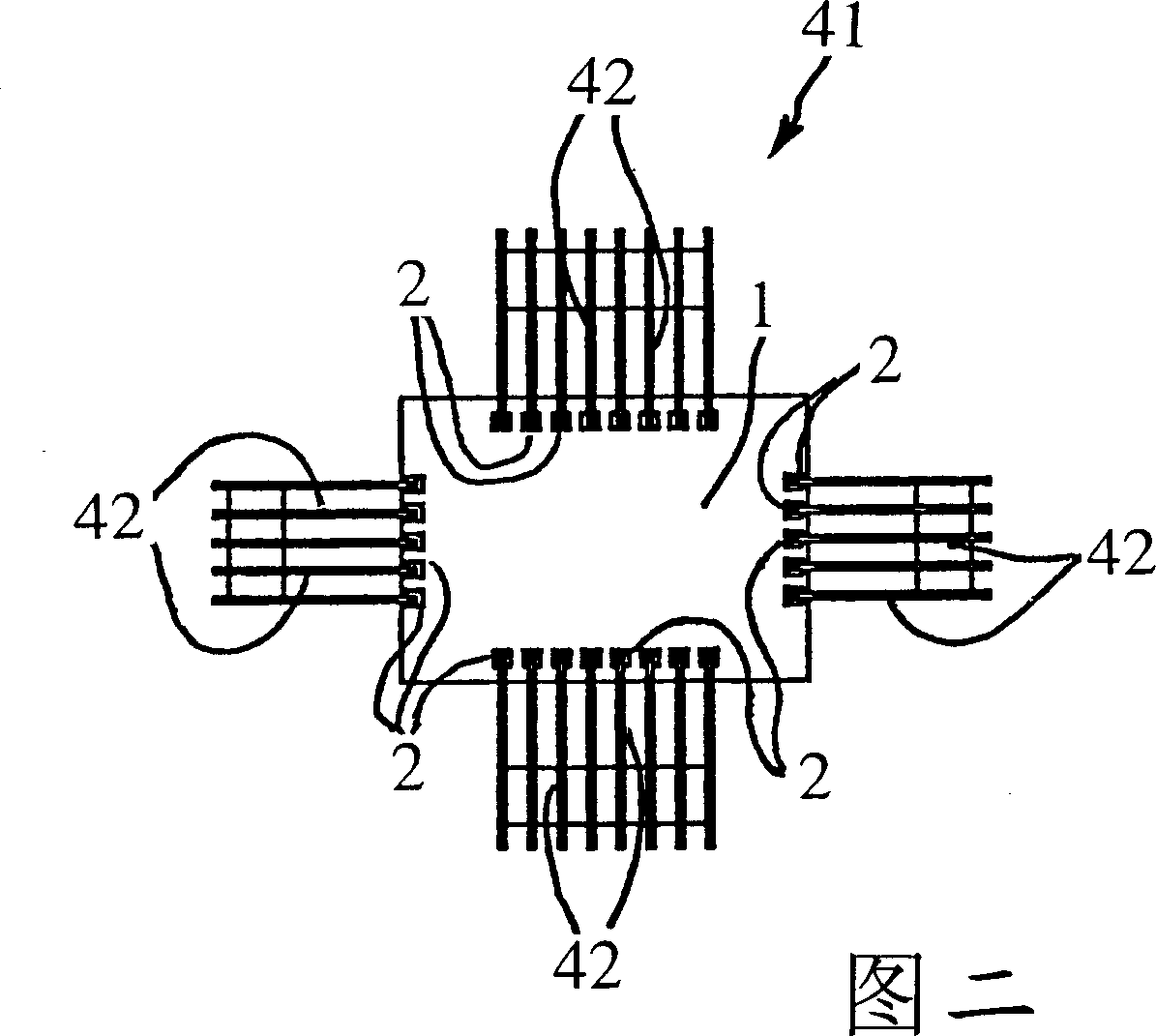

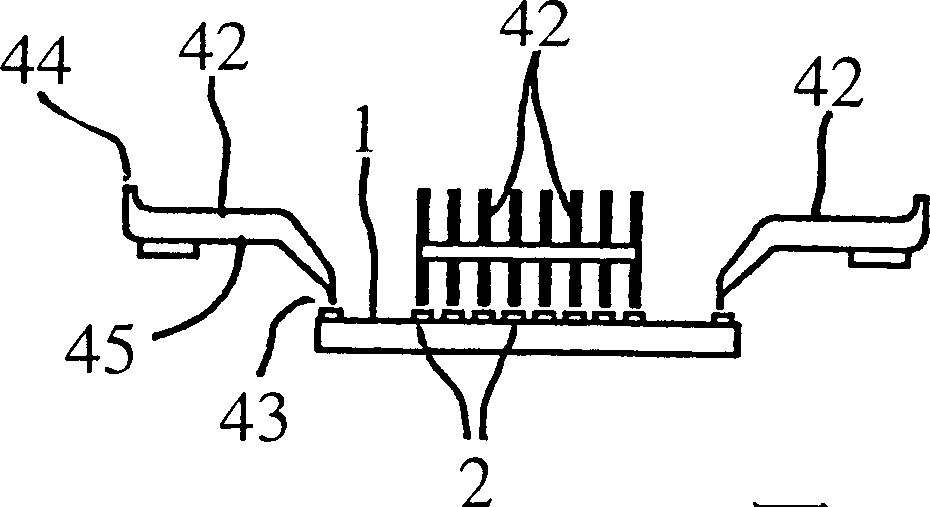

[0053] The first embodiment of the present invention is shown in Fig. 4 to Fig. 21 . FIG. 4 is an arrangement diagram of electrode pads on a wafer base, and FIG. 5 is an arrangement diagram of electrode pads of a circuit network. As shown in FIG. 4 , on the wafer substrate 19 , the electrode pads 191 are arranged in a row and arranged in a rectangular (square) shape as a whole, and some parts of the four corners are not provided with electrode pads. As shown in FIG. 5 , in the circuit network 20 , the electrode pads 120 are arranged in a row and arranged in a rectangular shape as a whole. The electrode pads 191 of a chip of the above-mentioned wafer substrate 19 and the electrode pads 120 of the circuit network 20 are formed to face each other, and have a consistent positional relationship. Embodiment 1 is an illustration for a contactor having the following characteristics: the contactor is effective in the electrical connection and electrical conduction between the aforemen...

Embodiment 2

[0063] 22 to 27 are diagrams showing a second embodiment of the present invention. In Embodiment 2, the case where the electrode pads are arranged in a staggered manner is taken as an example for description.

[0064] As shown in FIG. 22 , the first and second vertical contactors 112 , 212 are in a pair structure such that the outer contactor 22 and the inner contactor 21 are arranged opposite to the electrode pad 191 . In other words, the beam portion from the input portion 13, the output portion 14 of the vertical contactor 112, 212 to the deformation portion 15 extends to the outer electrode pads 191 arranged in a quadrangular shape; and the above-mentioned vertical contactor 112, 212 is They are arranged opposite to the outer electrode pads 191 arranged in a zigzag pattern. Furthermore, the beam portions from the input portion 13, the output portion 14, and the deformation portion 15 of the vertical contactors 112 and 212 extend to the inner electrode pads 191 arranged in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com