Drum type washing machine

A drum-type washing machine and drum-type technology, applied to other washing machines, washing machine control devices, washing devices, etc., can solve the problems of time-consuming and labor-intensive operations, inability to eliminate 61 folds of laundry, and time-consuming and labor-intensive opening of folds, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] Hereinafter, a drum-type washing machine according to an embodiment of the present invention will be described with reference to the drawings. In addition, the following description is a specific example of this invention, and does not limit this invention.

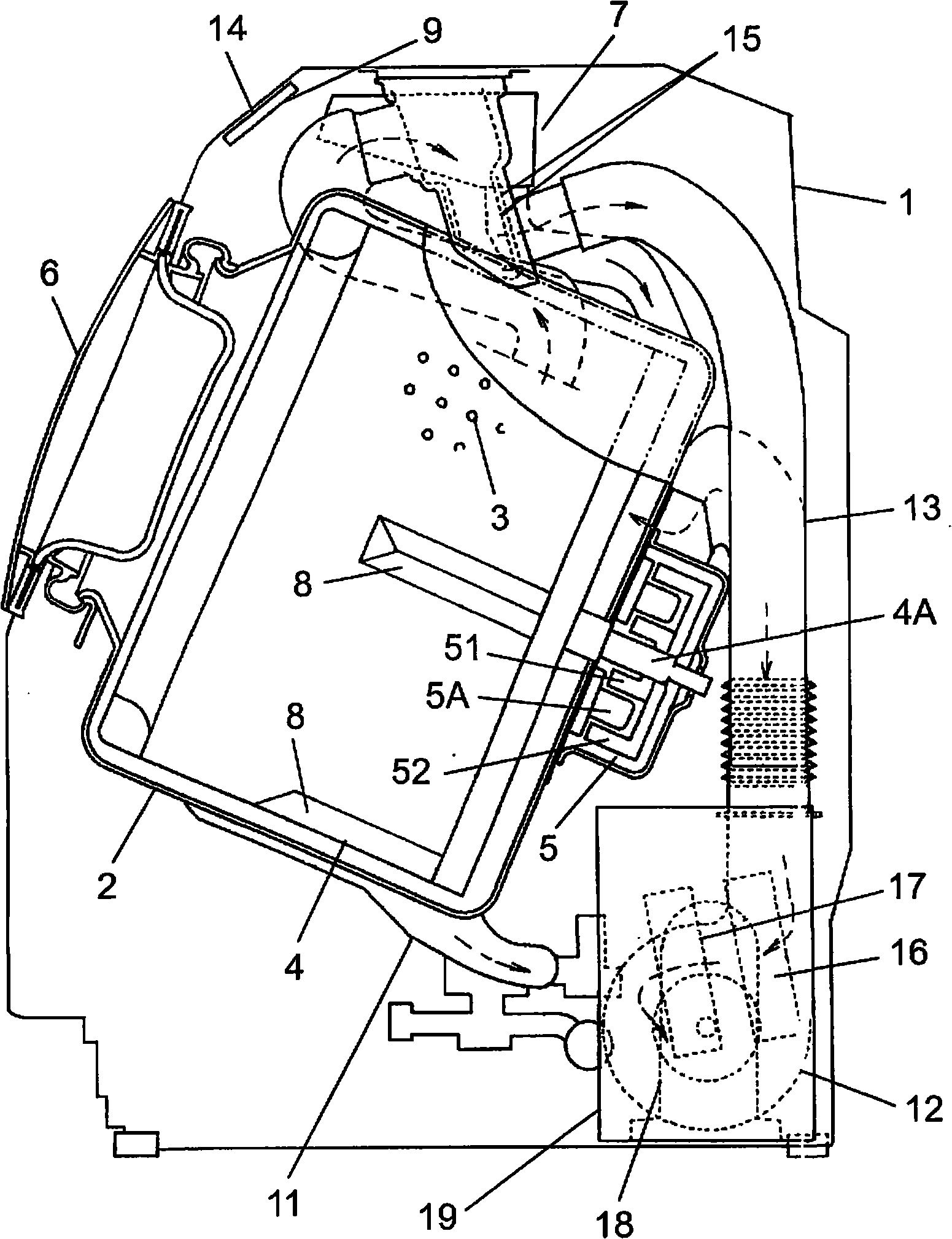

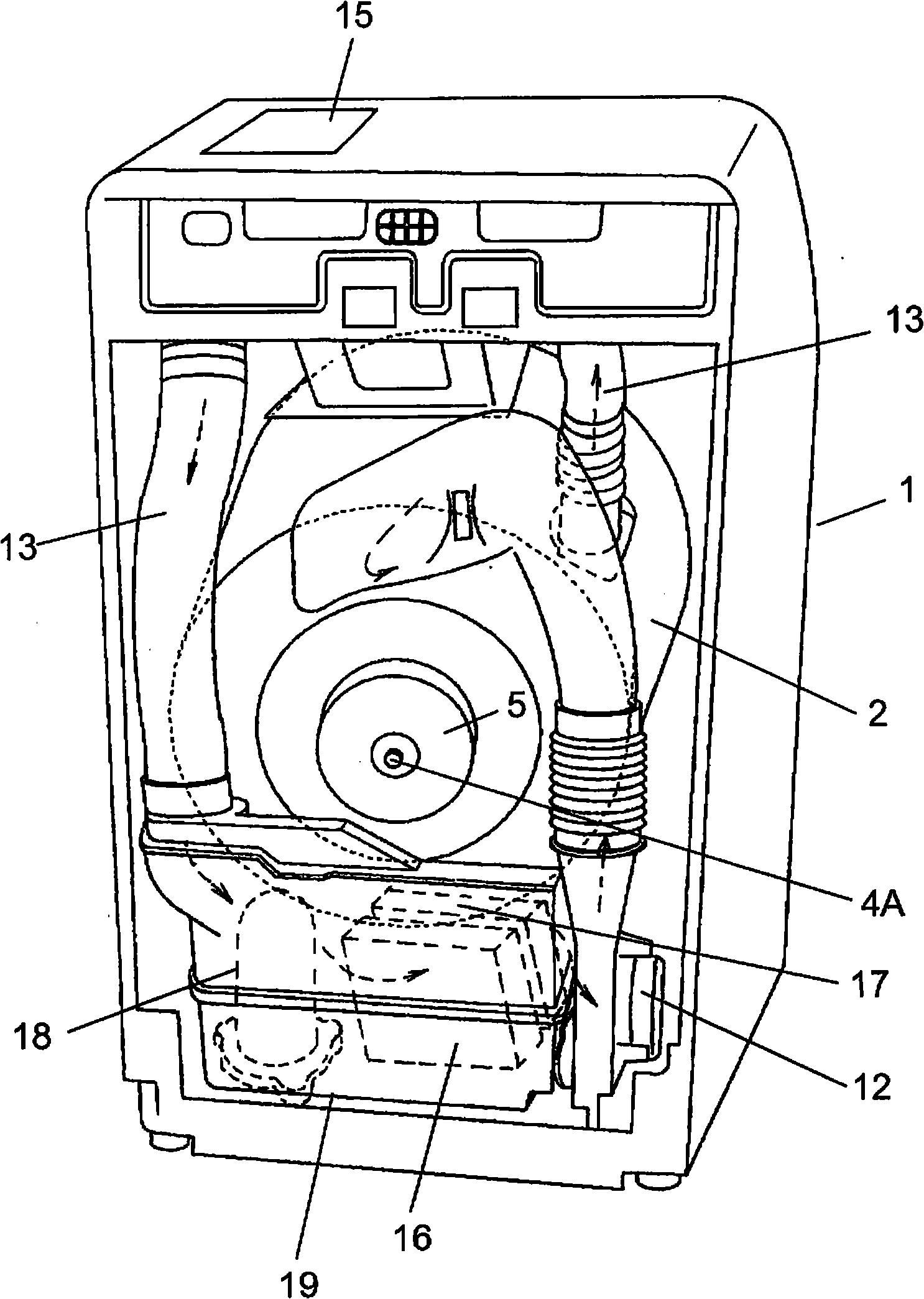

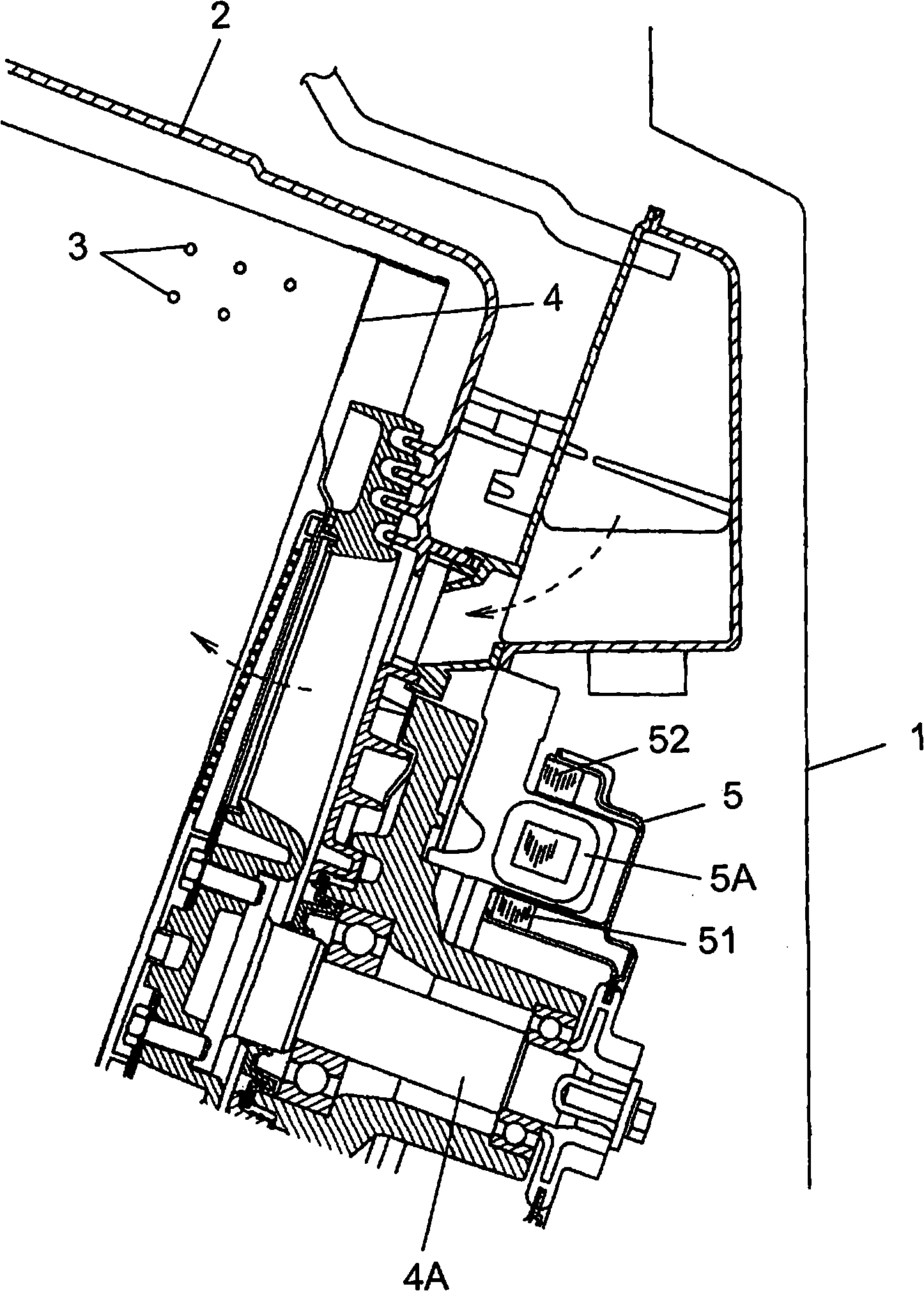

[0032] figure 1 It is a cross-sectional view showing the structure of the front-loading-type washing machine according to the embodiment of the present invention. figure 2 yes means figure 1 Rear view of the interior of the front load washing machine shown. image 3 yes means figure 1 A sectional view of about half of the motor mounting portion of the front-loading washing machine shown.

[0033]The washing machine has a housing 1 , a water tank 2 , a rotary drum 4 , a motor 5 and a door 6 . The water tank 2 is supported in the casing 1 by a suspension structure. A bottomed cylindrical rotary drum 4 formed with a plurality of holes 3 is arranged in the water tank 2 . The motor 5 is used to drive the rota...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap