Cable arrangement for robot arm, and industrial robot utilizing the same

一种工业用机器人、机器人手臂的技术,应用在机械手、制造工具、焊接设备等方向,能够解决电弧紊乱等问题,达到减轻负担的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

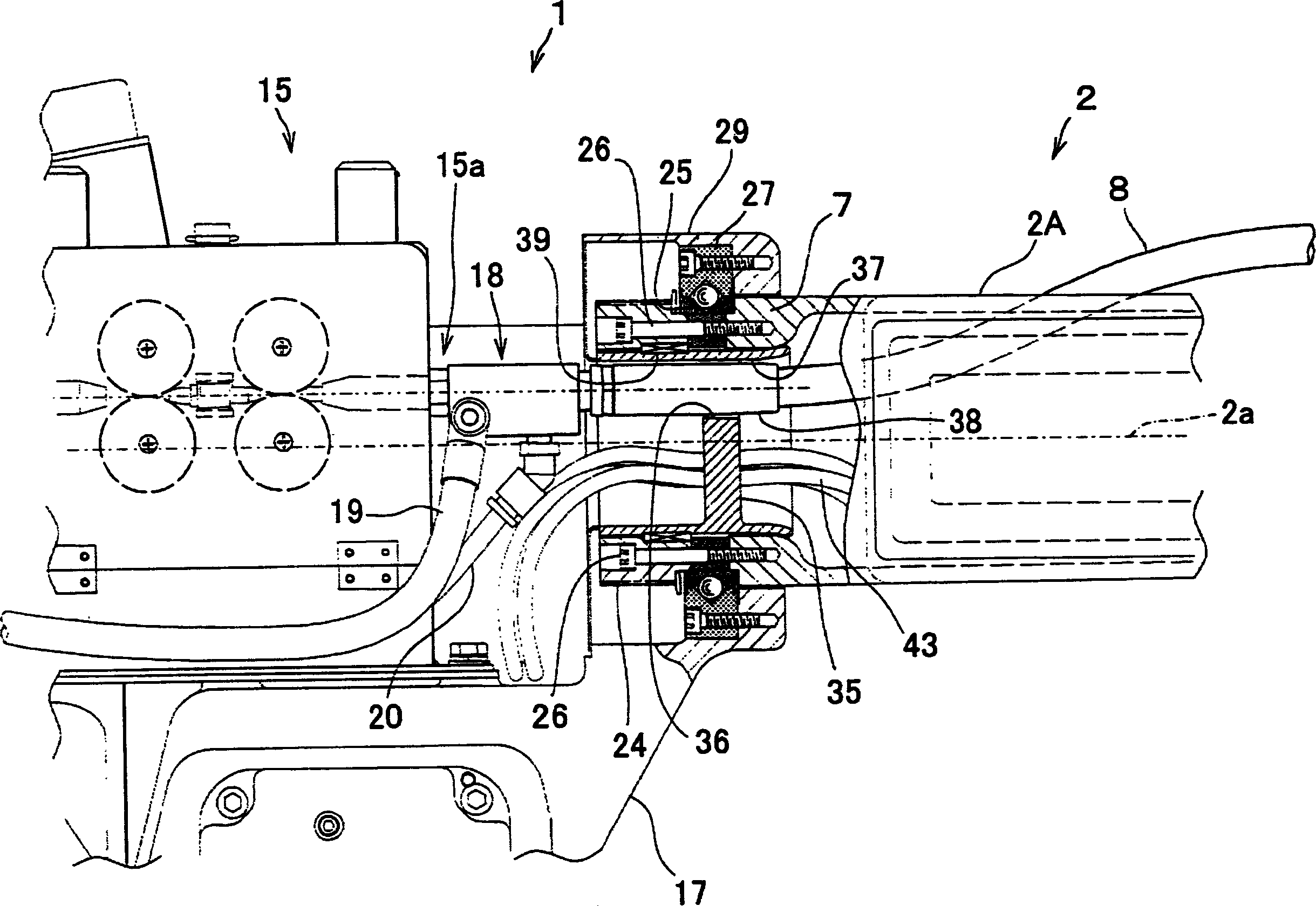

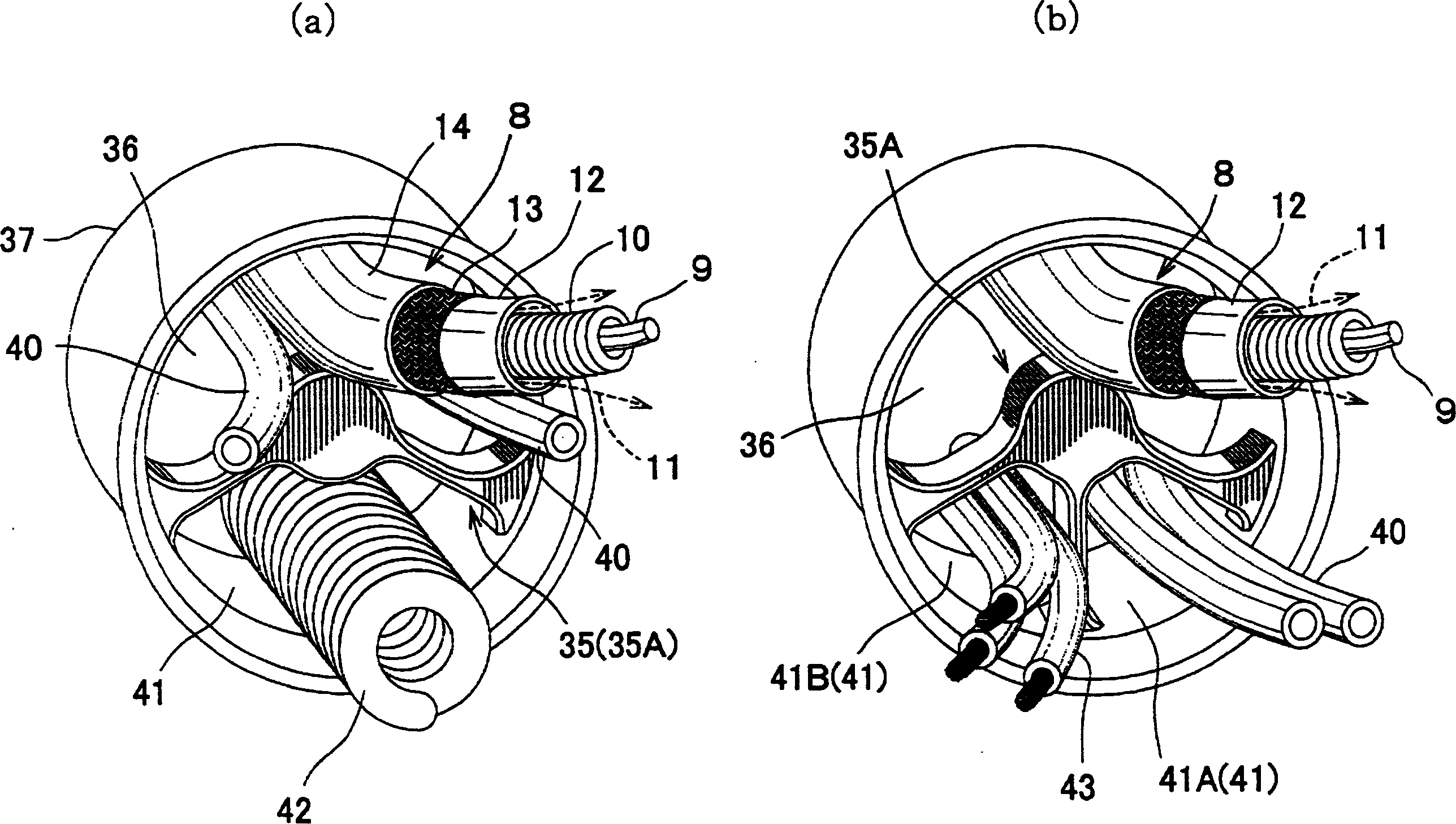

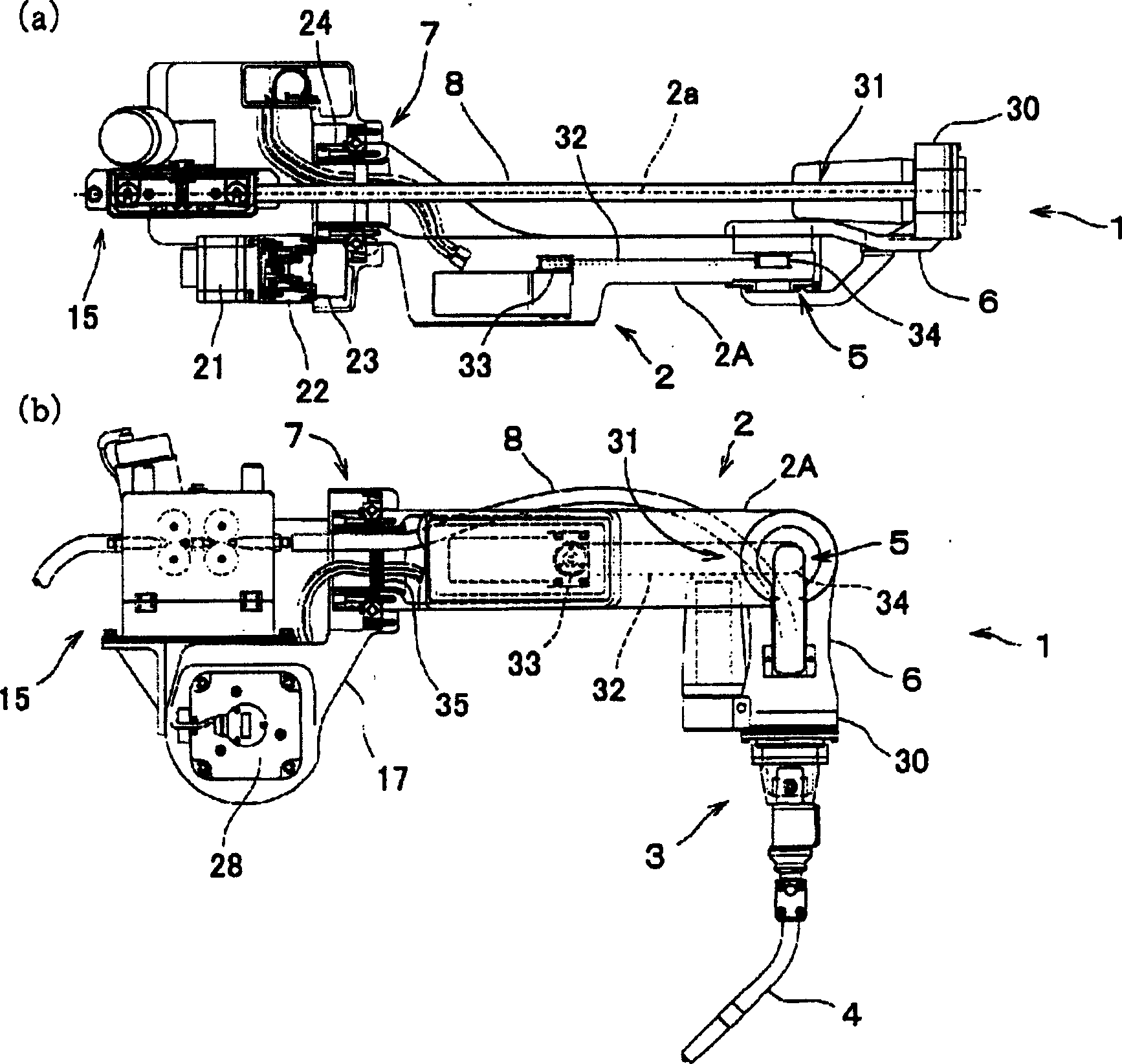

[0050] Hereinafter, the arrangement structure of the cable etc. of the robot arm of this invention and the industrial robot equipped with it are demonstrated in detail based on drawing which shows embodiment. Figure 4 and Figure 5 The articulated arc welding robot 1 using the present invention is shown. (a) of Fig. 4 is the front view of the robot, (b) is its II-II line view, Figure 5 (a) is the III-III line view in Fig. 4(a), and (b) is the top view of the robot. Apart from Figure 5 Except (a), the upper arm 2 using the present invention is shown in any of the figures, and its shape and its mounting form are described. image 3 It is a plan view and a front view drawn so that the arrangement structure of the cable etc. of the upper arm 2 can be seen.

[0051] This arc welding robot 1 has six joints that perform actions indicated by arrows in FIG. The sixth axis 3 among the six axes of the arc welding robot rotates a welding torch 4 attached to a wrist as an end effect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com