Variable turbo supercharger and method of driving the same

A turbocharger, a variable technology, applied in the direction of machines/engines, fluid pressure actuators, mechanical equipment, etc., can solve the problems of taking up more space, the slide valve is easily affected by the flow force, and is not so large , to achieve the effect of a simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] An embodiment of the present invention will be described below based on the drawings.

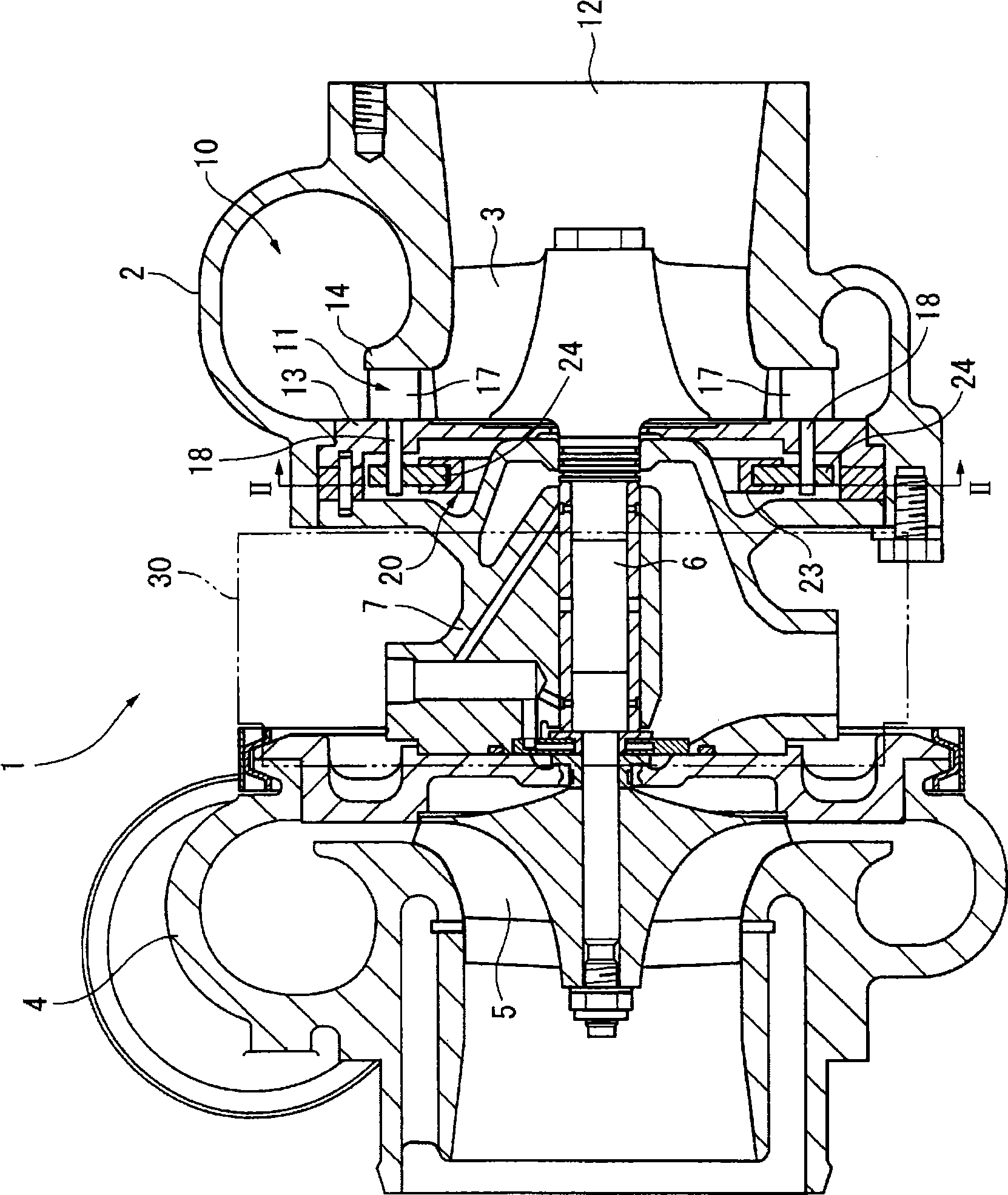

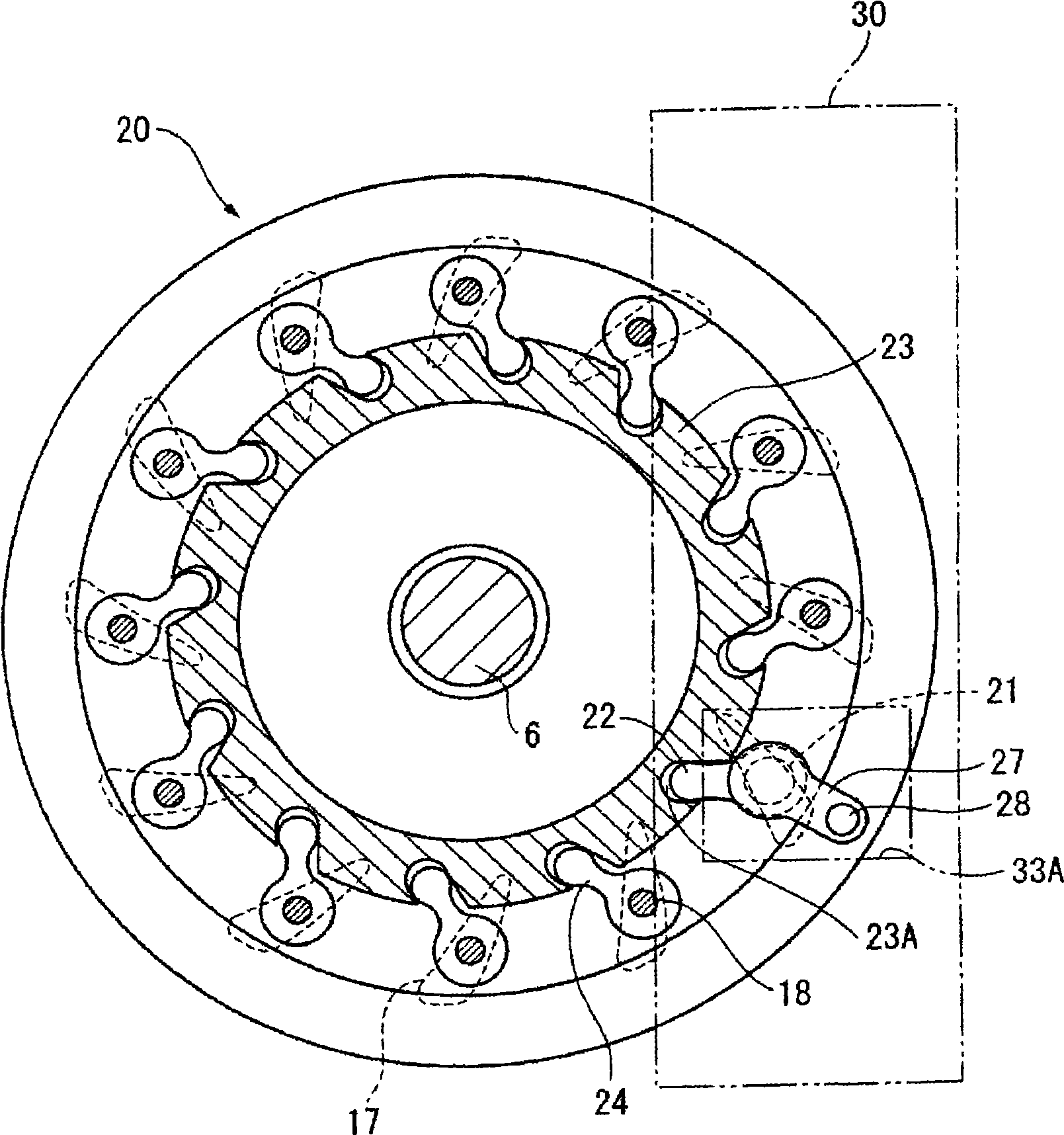

[0047] figure 1 It is a sectional view of the variable turbocharger 1 of this embodiment. The variable turbocharger 1 is provided in an engine body not shown in the figure, and has a turbine on the right side in the figure and a compressor on the left side. The turbine 3 is accommodated in a turbine housing 2 on the turbine side, and the compressor impeller 5 is accommodated in a compressor housing 4 on the compressor side. The shaft 6 is integrated with the turbine 3 , and the compressor impeller 5 is mounted on the front end of the shaft 6 . The shaft 6 is rotatably supported by the center case 7 . Therefore, the rotation of the turbine 3 rotated by the exhaust gas is transmitted to the compressor impeller 5 via the shaft 6 , and the intake gas is compressed and supercharged by the rotation of the compressor impeller 5 .

[0048] The turbine casing 2 is provided with a scroll-s...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap